surface treatment

Aalberts surface technologies Uttendorf

about this location

welcome to the Helpfau-Uttendorf plant in Austria

In 1987, the AHC Oberflächentechnik plant was established at the St. Pantaleon site (Upper Austria). In 2015 AHC Oberflächentechnik took over the MST Oberflächentechnik plant, which was founded in 2006 in Helpfau-Uttendorf (also Upper Austria). Since then, AHC Oberflächentechnik has continued its operations at the Helpfau-Uttendorf site. AHC Oberflächentechnik, which has been part of Aalberts since 2001, was renamed Aalberts Surface Technologies Ges.m.b.H. and has been working for its customers under this name ever since.

Through further education and training of our 35 employees and apprentices, we offer the coating of functional surfaces, especially wear and corrosion protection for aluminum components with the processes hard anodizing HART-COAT® and technical anodizing at the highest level.

With our fully automatic large parts plant and the manually operated small parts plant as well as our marking laser, we can offer our customers a wide range of surfaces. On the basis of our certifications in the automotive industry (IATF 16949:2016) and aviation (AS 9100D) as well as ISO 9001:2015, we try to achieve a high level of quality and reliability.

our services for surface finishing in Uttendorf

process overview

| process | max. size in mm | max. weight in kg |

| Color anodizing red | 600x400x600 | 5 |

| Anodizing black | 3000x1250x700 | 1000 |

| Anodizing colorless | 3000x1250x700 | 1000 |

| HART-COAT® black | 3000x1250x700 | 1000 |

| HART-COAT® colorless | 3000x1250x700 | 1000 |

| Surface marking | 680x500x700 | on request |

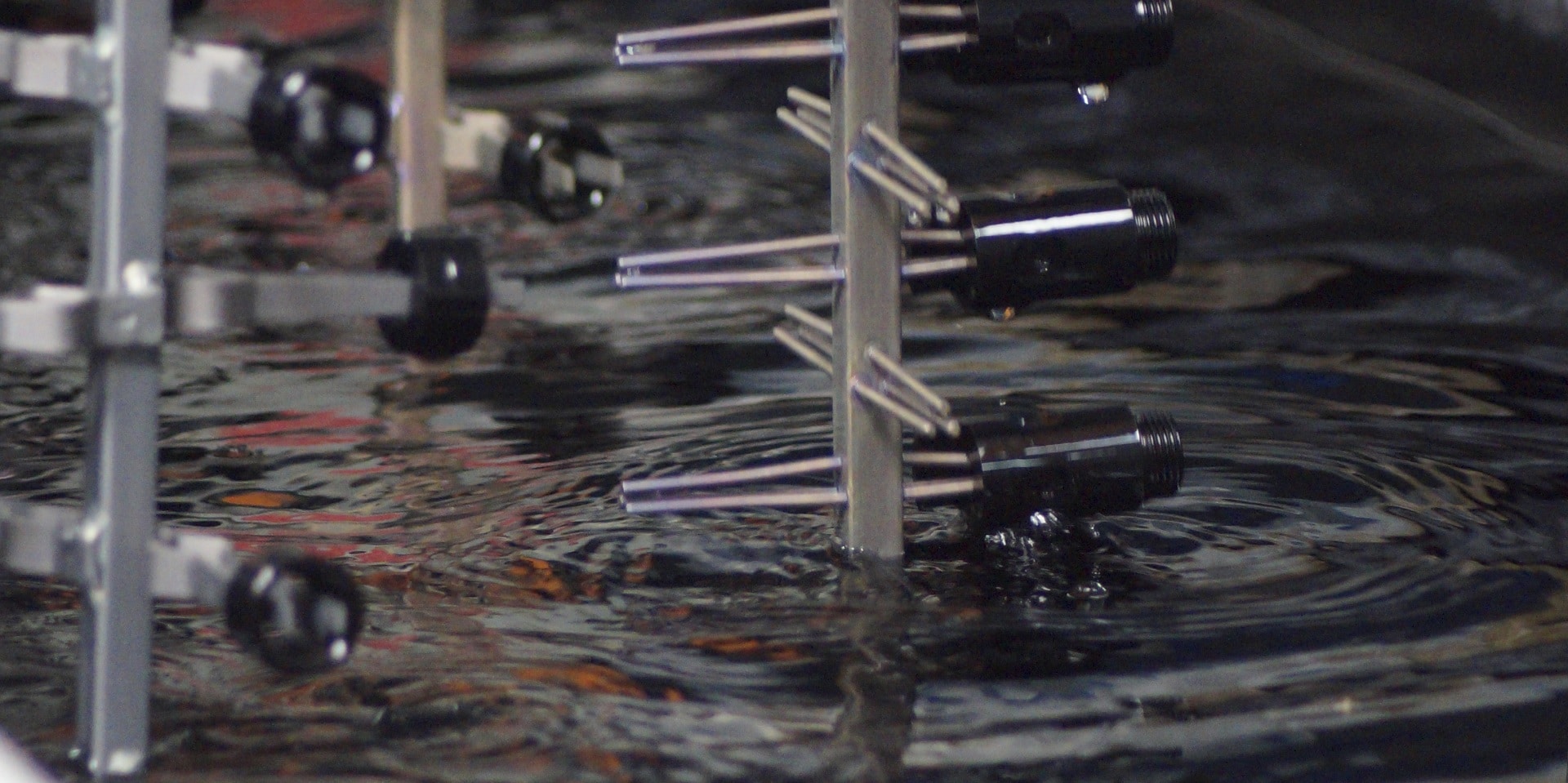

large-scale plant in Helpfau-Uttendorf

HART-COAT® – 2 baths

The HART-COAT® process, or HC for short, is an electrolytic treatment of aluminum which results in the formation of a hard and thick aluminum oxide layer. With HART-COAT® surface refinements we hard anodize in Helpfau-Uttendorf workpieces which require the highest degree of corrosion protection, wear resistance, dimensional accuracy, sliding behaviour or insulation. HART-COAT® coatings are characterized by good adhesion to the base material. Compared to conventional anodized coatings, HART-COAT® coatings are thicker and more wear-resistant.

HART-COAT® surface finishing is used in almost all technical areas where aluminum parts are used that are subject to special functional requirements.

Max. Dimensions: 3,000 mm x 1,250 mm x 700 mm (WxHxD)

- Color: Natural or black

- PTFE coating

- Sealing

- Cold sealing, hot sealing, duplex

TE-Technical anodizing – 1 bath

Technical anodizing is a coating for the functional, but also decorative refinement of aluminum. The coating is applied in an acid electrolyte at temperatures slightly below room temperature. The workpiece is connected as anode. In the course of the treatment, the workpiece surface is transformed into a porous (dense), hard and wear-resistant aluminum oxide layer. By sealing the pores are closed and the corrosion resistance is greatly improved. The layer thickness varies between 10 and 30 µm depending on the intended use and alloy.

Technically anodized aluminum parts offer good corrosion and wear protection in almost all industries.

Max. Dimensions: 3,000 mm x 1,250 mm x 700 mm (WxHxD)

- Color: Natural or black

- PTFE coating

- Sealing

- Cold sealing, hot sealing, duplex

small parts plant in Helpfau-Uttendorf

HART-COAT® – 2 baths

Max. Dimensions: 600 mm x 400 mm x 600 mm (WxHxD)

- Color: natural, black or red

- PTFE coating

- Sealing

- Cold sealing, hot sealing, duplex

TE-Technical anodizing – 1 bath

Max. Dimensions: 600 mm x 400 mm x 600 mm (WxHxD)

- Color: natural, black or red

- PTFE coating

- Sealing

- Cold sealing, hot sealing, duplex

Pre-treatment: Matt and bright pickling

Max. Dimensions matt pickling: 600 mm x 400 mm x 600 mm (WxHxD)

Max. Dimensions bright pickling: 500 mm x 400 mm x 600 mm (WxHxD)

surface marking or partial component decoating

With our laser station TurMark Station 5000 from Trumpf we can offer marking or partial decoating of coated components. This is where the “everything from a single source” solution comes into its own, as we can save time and money for our customers due to the interlocking work steps.

The installation space of the laser is 680 mm x 500 mm x 700 mm (WxHxD) and the marking area: 385 mm x 385 mm.

downloads

Aalberts surface technologies offers security. We want to offer you the greatest possible security. That is why our Aalberts surface technologies sites are certified.

certificates

general terms and conditions

our inhouse processes

We are the right partner for both new parts business and component maintenance. In addition to offering various coating processes, like anodizing and hard anodizing, our competence also includes partial coating of components and keeping technically necessary areas of the components free from coating.

industries we serve

contact & directions

Aalberts Surface Technologies Ges.m.b.H