metal layers are brilliant performances

electroplating

what is electroplating?

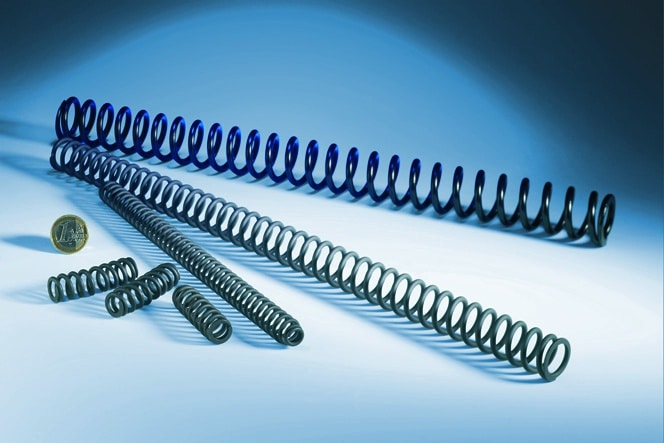

The creation of metallic coatings using electroplating techniques is a process with a long tradition. Aalberts surface technologies offers professional, state-of-the-art electroplating services with many kinds of metal finishes (nickel, chrome, copper, etc.). It is our goal to improve the properties of your components! Some of our electroplating processes enhance their gliding properties and increase their resistance to wear and corrosion.

electroplating of metals

Electroplating involves the use of direct current to deposit metallic coatings onto workpieces. The type of metal used as anode is determined by the coating to be deposited onto the cathode. Depending on the desired function or decorative purpose, we offer the following electroplating metal finishes:

- Chrome

- Gold

- Copper

- Nickel

- Nickel sulfamate

- Silver

- Tin

Please do not hesitate to get in touch with us if you are looking for comprehensive and non-binding advice on the surface treatments and surface finishes suitable for your components.

Continue reading to learn more about the advantages and features of our custom electroplating services.

electroplating - technology and process

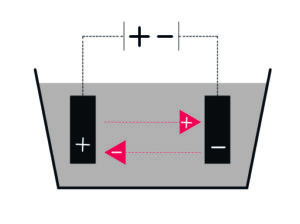

Electroplating covers a wide range of applications for research and practice: During electroplating, the parts to be finished are immersed in special electrolytes. Electrochemical and chemical reactions occur.

In electrochemical processes, metal ions are loosened from the anode (the metal to be applied) and deposited onto the cathode (the object to be coated) through electric current. The results are influenced by different parameters, such as the anode, the material, the electrolyte composition, the temperature and the current.

Products finished with high-tech electroplating (Tin, silver and gold)

beyond the limits of common electroplating processes

As for materials which are difficult to electroplate, we prefer to perform chemical pre-treatments and, in some cases, sandblasting or frictional grinding. Thus, we prevent embrittlement in high-strength steels. Steel alloys with high copper, lead or manganese contents require appropriate preliminary treatments in order to allow the electroplated coating to unfold its full durability and protective effect. Our offer comprises all common treatments, such as degreasing by pickling, degreasing by boiling, electrolytic degreasing and deoxidation. Using temperature sensors, we record the temperatures during the burn-in process so that you can keep track of the hydrogen de-embrittlement of your batch.

We at Aalberts surface technologies attach great importance to the further development and optimization of tried and tested processes. That is why we perform in-depth research activities in the area of innovative, economic and high-performance processes: We adjust every single set screw and take inventive approaches to future technologies. The focus of our developments is on functional electroplating processes. Apart from that, we offer a wide range of decorative finishes, a great variety of which can be easily combined with our technical and functional surface coatings.

gold plating - for good solderability

Being able to turn non-precious metals into gold has been a dream of mankind for as long as anyone can remember. Although we cannot fulfill this dream either, we can finish metallic components with gold plating. During electroplating, a steady current flow from an electrolyte enriched with salts and gold ions deposits the gold onto the component’s conductive surface. Gold coatings are generally characterized by high ductility, resistance to tarnishing, good solderability and a low, specific electrical resistance.

We offer both common gold plating and gold/cobalt alloy coatings, which are more resistant to wear and harder. Both types of surface coatings are suitable, for instance, for electroplating plug connectors for the electronics industry. However, these coatings are also worth considering when it comes to batteries, professional halogen lamps, components used in the aerospace industry, radar equipment and high-temperature soldering.

electroplating with copper - the basis for nickel

Copper serves as a base for further electroplated coatings, such as tin or nickel electroplating. The procedure starts with the deposition of bright, microcrystalline and ductile copper coatings in an electrolytic process. The advantage of a finished copper-nickel coating system: It fulfills numerous requirements when it comes to corrosion protection accompanied by attractive looks. Copper is characterized by good covering properties, high ductility and excellent electrical and thermal conductivity. When applied as a base coating, it counteracts strains between the component and the coating system. What is more, copper coatings are also suitable for subsequent passivation.

nickel electroplating - smooth nickel coatings from matte to shiny

Nickel electroplating is a process during which metallic workpieces are coated with nickel. Nickel has a silvery color with a slightly yellowish tint. The deposition of the nickel coating occurs in an electrolytic way via so-called nickel electrolytes. Subtle irregularities on the workpiece surface are compensated by special organic additives contained in the electrolyte and by the adjustment of certain process parameters. These measures result in the creation of a shiny finish. Nickel electroplating increases both the material’s corrosion resistance and electrical conductivity.

When it comes to decorative applications, nickel-plated components are a possible alternative to chrome coatings. Be it matte or polished to a shine, nickel coatings can be customized to your individual needs. Aalberts surface technologies has been a successful provider of high-quality nickel electroplating services for the automobile and electronics industries for years.

nickel sulfamate - electroplating technology for the repair of components

Nickel sulfamate is a complex chemical compound used in electrolyte solutions for the deposition of relatively thick and pure nickel layers. This surface treatment technology is particularly suitable for the repair of damaged and defective components. Nickel sulfamate coatings are very ductile and offer good protection against wear and corrosion. Beyond that, the coatings are ideal for machining.

expert silver electroplating services

Silver plating involves the use of current in electrolytes enriched with silver salts to deposit silver onto conductive workpiece surfaces. Silver coatings are characterized by excellent electrical conductivity, good chemical resistance and high ductility, which is why they are ideal for soldering. What is more, they reduce transition resistances and have a self-lubricating effect.

Due to their excellent electrical conductivity, silver coatings are used, inter alia, in the electronics, high-voltage and telecommunications industries. Besides, Aalberts surface technologies has a long history of cooperating with renowned companies from the chemicals industries. Stainless steel connectors and shut-off valves, for example, are finished with silver plating to reliably prevent fretting and corrosion.

tin plating for electromagnetic shielding

Tin plating involves the use of current in electrolytes enriched with tin salts to deposit tin onto conductive workpiece surfaces. Aalberts surface treatment offers tin plating services for aluminum alloys as well as for non-ferrous metals, ferrous materials, stainless steel, titanium materials and die-cast zinc parts.

The advantages of tin coatings:

- Good solderability

- High ductility

- Good electrotechnical properties

- Excellent corrosion protection, also on copper and steel

- Resistant to organic acids (in the absence of oxygen)

- Self-lubricating

Tin plating is primarily used for technical parts which have to be conductive, solderable and electromagnetically shielded, as is the case, for example, with housings of electric plugs or plug contacts. Self-lubricating bearings also fall within the scope of application of tin plating. Please do not hesitate to get in touch with us if you would like to discuss the application possibilities and viable alternatives.

downloads

industries we serve

frequently asked questions

In the past, chrome plating would be used to protect metal parts (such as door handles, bumpers or trims) against corrosion. Today, many components are made from plastics. If such components are chrome-plated at all, it occurs partially for decorative purposes only.

When it comes to drives, some parts are still finished with hard chrome plating to protect them against wear.

Hard chrome plating is usually used for this purpose.

This depends on the field of use.

When it comes to decorative corrosion protection, attractive and perfect finishes as well as targeted design effects can be created with electroplating processes and coating systems involving copper/nickel/chromium.

The automotive industry attaches great importance to long-term corrosion protection and attractive finishes, features which must also be able to withstand high temperatures. Cathodic corrosion protection fulfills these criteria. These finishes are achieved with galvanically deposited zinc and zinc alloys.

Permanent protection against wear and corrosion can also be achieved with hard chrome plating.

We create the following electroplating metal finishes: chrome, DURALLOY® (hard chrome), gold, copper, nickel, nickel sulfamate, silver, zinc, zinc-iron, zinc-nickel and tin.

process locations

Any questions? Contact us directly or select a process location near you.

Chicago (Illinois)

United States 41.9897386-87.7325852 sales@ppc1904.com +1 773 583 3333 show locationCormenon

France 47.97014060.8907598 ast.cormenon@aalberts-st.com +33 (0) 2 54 73 45 40 show locationDeurne

the Netherlands 51.45566135.7704517 deurne@aalberts-st.com +31 493 352 820 show locationEindhoven

the Netherlands 51.43406225.4346575 eindhoven@aalberts-st.com +31 402 5076 07 show locationPiedmont (South Carolina)

United States 34.7468007-82.4056893 sales@rmf-sc.com +1 864-277-0420 show locationVillers-Cotterets

France 49.24847423.1020097 info.villers@aalberts-st.com +33 323 9601 01 show locationUnsere Verfahren

Wir bieten weltweit alle Arten von Wärmebehandlungsprozessen an. Unsere Anlagen sind logistisch eng miteinander verknüpft, so dass Ihnen alle Verfahren zur Verfügung stehen. Erfahren Sie mehr zu unseren Wärmebehandlungsverfahren.

Heiß-Isostatisches Pressen (HIP) dient der Beseitigung von Porosität. Sie benötigen bei Lötverbindungen eine hohe mechanische Haltbarkeit und Unempfindlichkeit bei hohen Temperaturen? Wir bei Aalberts surface technologies bieten die Lösung durch Hartlöten (brazing).

Polymerbeschichtungen können auf viele Grundmaterialien aufgebracht werden und bieten lang anhaltenden Schutz. Sie sind mechanisch besonders gut mit dem Untergrund verankert und bieten verbesserte Gleiteigenschaften und/oder hohe Verschleißfestigkeit.

Mit 40 Jahren Erfahrung in der kontinuierlichen Veredelung von reel to reel können Sie sich auf Aalberts surface technologies verlassen, um innovative Lösungen zu finden. Unser Service umfasst Trommelgalvanik, kontinuierliche selektive Galvanik und Gestellgalvanik.

Fast alle metallischen Grundwerkstoffe können mit unseren selbstentwickelten und patentierten Verfahren durch Oberflächenbeschichtungen in ihren Eigenschaften optimiert werden, egal ob sie besonders hart, glatt, verschleißfest oder korrosionsbeständig sein sollen.

Discover our services

We offer all types of heat treatment processes. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. For a complete list and description of heat treatment technologies please select the button.

Hot isostatic pressing (HIP) is used to eliminate porosity. Do you need high mechanical durability and insensitivity to high temperatures for solder joints? We at Aalberts surface technologies offer the solution through brazing.

Polymer coatings can be applied to a wide variety of base materials and offer long-lasting protection. They are particularly well anchored mechanically to the substrate. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance.

With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. Our service includes barrel plating, continuous selective plating and rack plating.

Almost all metallic base materials can have their properties optimised by surface coatings using our proprietary and patented processes, regardless of whether they should be particularly hard, smooth, wear-resistant or corrosion-resistant.

The Aalberts websites use cookies (read more) to analyse website usage and improve usability. We also use third party tracking-cookies to measure user preferences, enable content sharing on social media and interest-based advertising. If you hit 'accept' you allow to us to place the different types of cookies.

privacy overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |