aluminum oxide polymer composite layers

hard anodizing

what is hard anodizing?

Hard anodizing is the term used to describe the functional refinement of aluminum components as anode in special, cold electrolytes. This process is sometimes also referred to as hard coat anodizing. Hard anodizing creates very thin, non-metallic conversion coatings. Parts of the base material become fully integrated with the coating, which results in an extremely high bonding strength of the anodic layers. Aalberts surface treatment offers two hard anodizing processes: NUCOCOMP® and HART-COAT®.

hard anodizing with NUCOCOMP®

NUCOCOMP® stands for hard-anodized aluminum oxide-polymer composite coatings. The coating process has been patented, among others, in Europe and in the USA.

hard anodizing with HART-COAT®

One of our core competencies, HART-COAT® laid the foundation for hard anodizing in Germany as early as at the beginning of the 1960s. Today, we serve customers from all key industries. Every year, more than 500 million components are finished with our reliable hard anodizing processes.

The advantages you benefit from when partnering with Aalberts surface technologies:

- Cutting-edge process technology for aluminum components in lengths of up to eight meters

- Great variety of processes for individual component properties

- Maximum precision with our own electrolytes

- HART-COAT® conforms to the ISO 10074 standard

- We are the market leader for hard anodizing processes in Germany and, thanks to many locations in Europe and China, we are well positioned when it comes to the implementation of international projects

NUCOCOMP®

When materials are finished with NUCOCOMP®, the base material is transformed into hard-anodized layers through anodic oxidation and the aluminum oxide layer’s simultaneous molecular bonding to polymers. This process creates an ideal bond between the coating and the base material. Due to the molecular polymer content, NUCOCOMP® offers chemical bond bridges when combined with specifically matched top coats so that an excellent bonding strength is created here as well.

Thanks to the very hard aluminum oxide, the NUCOCOMP® surface treatment technique scores with high, alloy- and process-dependent strength. When subjected to abrasion resistance testing (Taber Abraser test), the coating excels with outstanding resistance to wear. Often, it scores better than conventional, anodized coatings. NUCOCOMP® coatings have high corrosion resistance. When subjected to notched-bar impact testing, they show a fibrous fracture pattern, whereas conventional oxide layers burst in a brittle way similar to glass.

NUCOCOMP® creates an optimized micro structure on the surface: In friction pairings and friction tests, the composite layers show excellent gliding properties – so-called “seizures” as a result of poor lubrication could be excluded. Apart from that, NUCOCOMP® coatings can be easily dyed. Our standard colors include black, titan grey, blue, red, gold and green. The colored surfaces are more resistant to light than dyed conventional anodized coatings. NUCOCOMP®-H is the variant to go for when it comes to special requirements. This coating is even harder and offers even better wear and corrosion protection.

NUCOCOMP® is suitable for almost all aluminum alloys.

HART-COAT®

Hard anodizing is a surface coating process for the functional refinement of aluminum materials. Using electric current, we transform the workpiece surface into a hard, ceramic-like aluminum oxide layer. The new layer is created in the form of regular, hexagonal cells which, like honeycombs, are perpendicular to the workpiece surface. This columnar arrangement creates a particularly stable cell structure; each cell has a pore channel. As a result, HART-COAT® protects workpieces against wear and corrosion. Available in different variants and suitable for many post-treatment processes, HART COAT® is a very versatile type of coating.

As a result of the aluminum oxide’s metamorphosis, HART-COAT® coatings are extremely hard and wear-resistant. During the hard anodizing process, half of the oxide grows into the base material, whereas the other half grows out of it. This creates a particularly strong bond between the coating and the base material. The ceramic-like HART-COAT® layer is electrically insulating. It has low thermal conductivity and high dielectric strength. With increasing coating thickness, the dielectric strength increases, but not proportionally. When applied as a protective layer to the bottom ends of motor pistons, it is able to withstand extremely high temperatures for a short time. Depending on the requirements profile, special post-treatment processes can be implemented to further increase the wear and corrosion resistance or the gliding behavior.

| Temperature in °C | Heat conductivity in W/m·K |

| 25 | 20,9 |

| 50 | 18,4 |

| 100 | 19,2 |

| 150 | 18,5 |

| 200 | 18 |

Be it wrought alloys, cast alloys or die-cast alloys, almost all technically interesting aluminum alloys may receive a finishing with HART-COAT® coatings. Where possible, the following must be observed should you decide to have your components coated by us:

- No material, processing or surface defects

- No oil residues

- Protective, parts-specific packaging

- Machining before coating

- No foreign particles on the workpiece surface

- Thoroughly deburred and, if possible, rounded edges

- End distances must be taken into account

- Bleeder holes might become necessary

fields of application for materials coated with NUCOCOMP®

The combination of low-density aluminum and NUCOCOMP® opens up new possibilities when it comes to technical and decorative applications with increased quality requirements. NUCOCOMP® does not affect the base material’s flexural fatigue strength, which makes it particularly interesting for applications in the aviation sector.

further areas of application in which NUCOCOMP® excels:

- Automotive

- Electrical engineering

- Mechanical engineering

- Medical technology

- Packaging machines

fields of use of hard-coated materials

Thanks to its good wear resistance, hard-coated aluminum can replace more expensive, wear-resistant steel or other corrosion-resistant materials.

Hard-anodized aluminum is used to prevent contact corrosion, improve the gliding properties and increase the electrical or thermal insulation.

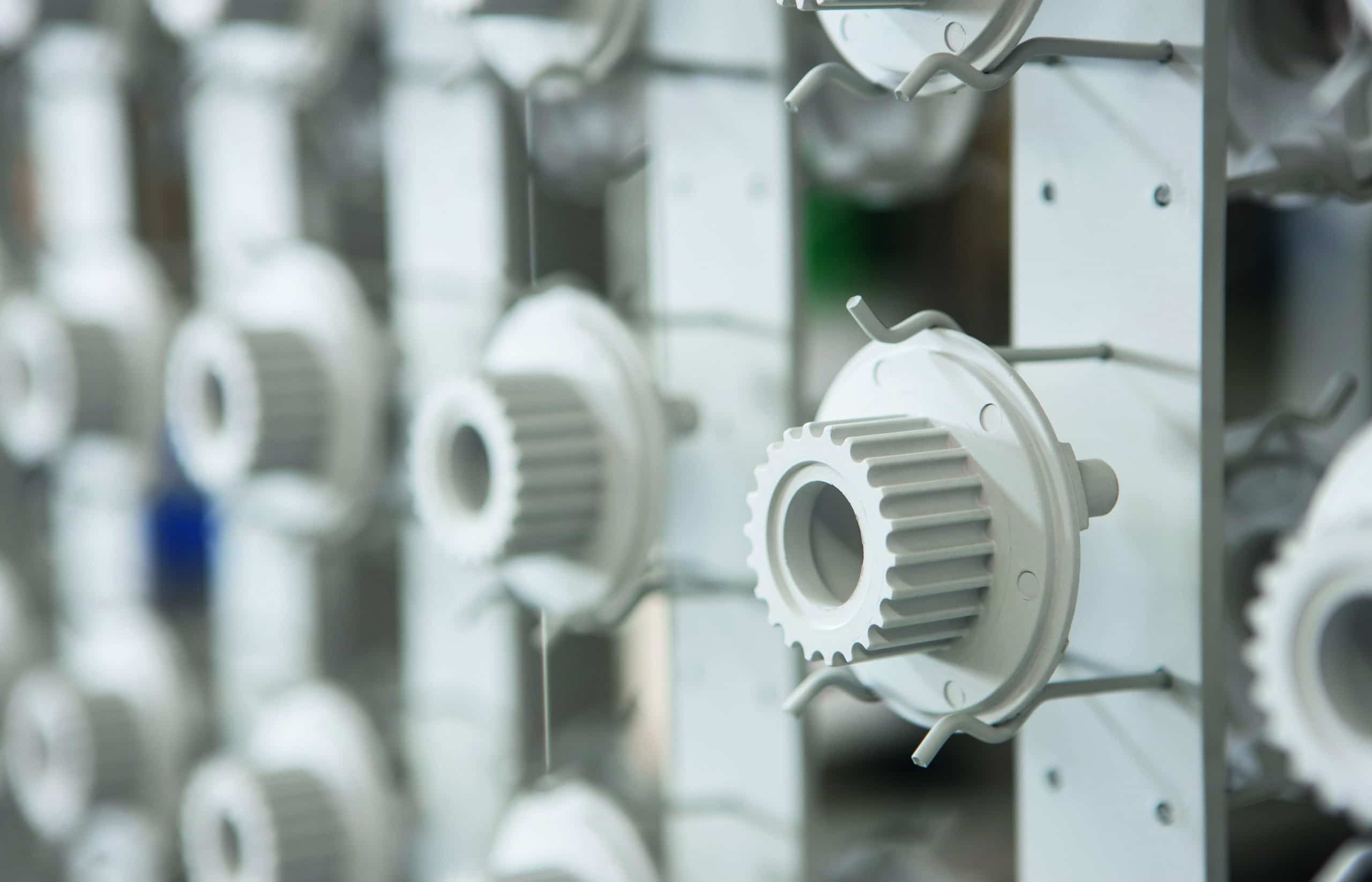

The density of aluminum alloys is equal to one third of the value of common iron materials and non-ferrous metals. When switching from steel or brass to aluminum, it is possible to significantly reduce the inertial forces of fast spinning machine parts. This results in new constructive possibilities and energy cost savings. HART-COAT® creates the required surface resistance.

examples of components which can be finished with HART-COAT®:

| Spacers | Bearing rollers |

| Iron bottoms | Bearing shells |

| Surgical instruments | Baffle plates |

| Damping chambers | Guide rollers |

| Nozzles | Mounting plates |

| Guided cylinders | Cam discs |

| Housings | Pneumatic and hydraulics cylinders |

| Holders and fixtures | Rollers |

| Levers | Coils |

| Heating plates | Transport levers |

| Insulators | Valves |

| Camera parts | Compressor wheels |

| Rocker arms | Toothed wheels and racks |

| Clamping devices | Centrifuges |

| Pistons | Cylinder heads |

| Clutch parts | Cylinder liners |

HART-COAT®-GLATT - especially smooth and wear-resistant

HART-COAT®-GLATT (HC-GL) is a process variant of HART-COAT® that produces very smooth and highly wear-resistant coatings on aluminum materials. HC-GL coatings are formed by anodic oxidation in a cooled acid electrolyte of special composition. We offer the process at our sites in Kerpen, Weiterstadt, Kirchheim as well as Göppingen-Voralb.

| Temperature in °C | Heat conductivity in W/m·K |

| 25 | 33,0 |

| 50 | 28,1 |

| 100 | 30,3 |

| 150 | 28,9 |

| 200 | 27,2 |

HC-PLUS surface treatment with PTFE

The anti-friction and corrosion behavior of HART-COAT® layers can be improved with the use of PTFE

(polytetrafluorethylene). The PTFE particles are applied to the HART-COAT® layer in a secondary process. This supplies optimum dry-lubricated performance, and the anti-adhesive properties of the surface and the anti-adhesive properties facilitate the cleaning of the surface.

HART-COAT-H2®

Our HART-COAT-H2® (HC-H2®) is a hard-anodic coating that due to its properties is predestined for applications in the field of hydrogen technology.

The anodic layer is particularly suitable for several aluminum components in the hydrogen path of fuel cells. Due to the dense and homogeneous layer structure as well as the only slight increase in roughness by the anodization process, there is a high general corrosion resistance. This higher resistance leads to longer durability of the electrically non-conductive anodic layer, which also increase the resistance to crevice corrosion or under-surface corrosion on sealing surfaces. The still intact aluminum oxide layer maintains the continuous barrier effect against hydrogen which is another advantage using HC-H2® instead of classic (hard) anodic layers.

- Anode recirculation blower (ARB)

- Hydrogen gas injector (HGI)

- Anode block as carrier module for ARB and HGI

- Hydrogen supplier module (HSM)

- Rails or manifolds for hydrogen distribution (from filler via pressure vessel to stack)

- Typical operating conditions for fuel cells range in temperature between -40 °C and +120 °C with a pressure load of up to 20 bar

- High requirements for corrosion resistance and impermeability in this area

- Test procedures for individual stresses (temperature change, impermeability and corrosion) or superimposed stresses (cyclical complex stresses) specified by OEMs and suppliers have been passed successfully

- Typical layer thicknesses range between 10 to 25 μm (+/- 5) with a typical layer hardness of > 450 HV 0.025

downloads

industries we serve

frequently asked questions

Yes, given that the aluminum alloy has the right mechanical properties.

The aluminum component’s mechanical properties (such as the tensile strength) must be suitable for the respective application.

Compared to steel, aluminum offers the following advantages:

- Aluminum is about two thirds lighter than steel

- Use of aluminum components in vehicles

- Fuel savings and thus less pollutant emissions

- Realisation of higher payloads

- Increased driving ranges of electric vehicles

- Aluminum is a good thermal conductor (Al: 170-220 W/mK, steel: 47-58 W/mK)

- Aluminum can be processed and shaped in countless ways

Usually, oil and residues compromise the quality of the coating. They can have an insulating effect that prevents the formation of a layer. Since hard-anodised coatings are conversion coatings, residues may later be visible on the surface. When oil or other residues come off during the coating process, the anodizing bath becomes soiled. Oil and residues inside the bath may reattach to the components when these are being removed from the bath.

Hard anodizing improves the wear and corrosion resistance of aluminum components. Hard-anodized coatings are thermal and electric insulators. Since they are electrically insulating, they can be used for electrical isolation. Components treated with hard anodizing may be temporarily exposed to high thermal loads. As the high temperatures reach the base material evenly and with delays only, they will not damage the components. Hard anodizing is the finishing method to go for when it comes to aluminum components for mass applications.

The maximum weight depends on the capabilities of the coating plant. As aluminum has a low density, it is not the weight, but rather the dimensions of the component which have to be considered.

These coatings are so-called conversion coatings. Parts of the base material become fully integrated with the coating, which results in an extremely high bonding strength of the anodic layers.

process locations

Any questions? Contact us directly or select a process location near you.

Helpfau-Uttendorf

Austria 48.168118113.1232299 uttendorf@aalberts-st.com +43 7724 44144 show locationBurg

Germany 52.2509811.88427 burg@aalberts-st.com +49 3921 4829 0 show locationCormenon

France 47.97014060.8907598 ast.cormenon@aalberts-st.com +33 (0) 2 54 73 45 40 show locationDzierżoniów

Poland 50.732931316.6280222 dzierzoniow@aalberts-st.com +48 748108508 show locationGöppingen

Germany 48.66539429.6795345 eschenbach@aalberts-st.com +49 7161 15688 0 show locationHangzhou

China 30.274084120.15507 hangzhou@aalberts-st.cn +86 (571) 5757 9777 show locationKaufbeuren

Germany 47.91376710.6489502 kaufbeuren@aalberts-st.com +49 8341 6601 0 show locationKerpen

Germany 50.88076.6800999 kerpen@aalberts-st.com +49 2237 502 0 show locationKirchheim-Heimstetten

Germany 48.151143811.7440283 muenchen@aalberts-st.com +49 89 990241-0 show locationKirkby-In-Ashfield

United Kingdom 53.1043759-1.2474762 nottingham@aalberts-st.com +44 1623 753 107 show locationWeiterstadt

Germany 49.897638.61422 weiterstadt@aalberts-st.com +49 6151 9806 0 show locationBerlin

Germany 52.528455313.5331206 berlin@aalberts-st.com +49 30 549904 0 show locationVillers-Cotterets

France 49.24847423.1020097 info.villers@aalberts-st.com +33 323 9601 01 show locationUnsere Verfahren

Wir bieten weltweit alle Arten von Wärmebehandlungsprozessen an. Unsere Anlagen sind logistisch eng miteinander verknüpft, so dass Ihnen alle Verfahren zur Verfügung stehen. Erfahren Sie mehr zu unseren Wärmebehandlungsverfahren.

Heiß-Isostatisches Pressen (HIP) dient der Beseitigung von Porosität. Sie benötigen bei Lötverbindungen eine hohe mechanische Haltbarkeit und Unempfindlichkeit bei hohen Temperaturen? Wir bei Aalberts surface technologies bieten die Lösung durch Hartlöten (brazing).

Polymerbeschichtungen können auf viele Grundmaterialien aufgebracht werden und bieten lang anhaltenden Schutz. Sie sind mechanisch besonders gut mit dem Untergrund verankert und bieten verbesserte Gleiteigenschaften und/oder hohe Verschleißfestigkeit.

Mit 40 Jahren Erfahrung in der kontinuierlichen Veredelung von reel to reel können Sie sich auf Aalberts surface technologies verlassen, um innovative Lösungen zu finden. Unser Service umfasst Trommelgalvanik, kontinuierliche selektive Galvanik und Gestellgalvanik.

Fast alle metallischen Grundwerkstoffe können mit unseren selbstentwickelten und patentierten Verfahren durch Oberflächenbeschichtungen in ihren Eigenschaften optimiert werden, egal ob sie besonders hart, glatt, verschleißfest oder korrosionsbeständig sein sollen.

Discover our services

We offer all types of heat treatment processes. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. For a complete list and description of heat treatment technologies please select the button.

Hot isostatic pressing (HIP) is used to eliminate porosity. Do you need high mechanical durability and insensitivity to high temperatures for solder joints? We at Aalberts surface technologies offer the solution through brazing.

Polymer coatings can be applied to a wide variety of base materials and offer long-lasting protection. They are particularly well anchored mechanically to the substrate. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance.

With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. Our service includes barrel plating, continuous selective plating and rack plating.

Almost all metallic base materials can have their properties optimised by surface coatings using our proprietary and patented processes, regardless of whether they should be particularly hard, smooth, wear-resistant or corrosion-resistant.

The Aalberts websites use cookies (read more) to analyse website usage and improve usability. We also use third party tracking-cookies to measure user preferences, enable content sharing on social media and interest-based advertising. If you hit 'accept' you allow to us to place the different types of cookies.

privacy overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |