overview

our processes - enhancing our client's businesses

surface treatment process for functional surfaces at Aalberts surface technologies

At Aalberts surface technologies, we offer global and regional customers innovative and heavy-duty surface finishes for a wide range of materials. As the world’s leading service provider for surfaces treatment and heat treatment with more than 80 years of experience and over 80 locations, we are the ideal contact for a wide range of surface finishing applications. Whether for the automotive industry, plastics industry or medical technology, we serve a wide range of industries worldwide.

we process more than one billion components per year

Nature has some ingenious ideas for designing functional material structures, perfectly adapted to their environment. This knowledge – from millions of years of evolution – is valuable information and inspiration for us in developing innovative functional processes. With the experience of more than eight decades, our wide range of surface techniques also include self-developed and patented processes. With our highly qualified and experienced staff, we will work closely with you to find the right process for your requirements. Contact us for extensive and individual consulting.

surface technologies of our different business units

In the five business units at Aalberts surface technologies, we offer a wide range of surface finishing processes aimed to improve material properties. Depending on the requirements, we improve your components in terms of corrosion protection, temperature resistance, wear protection and much more.

heat treatment

We offer all types of heat treatment processes. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. For a complete list and description of heat treatment technologies please select the button.

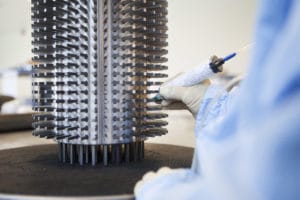

HIP | braze | heat treatment

Hot isostatic pressing (HIP) is used to eliminate porosity. Do you need high mechanical durability and insensitivity to high temperatures for solder joints? We at Aalberts surface technologies offer the solution through brazing.

polymer coating

Polymer coatings can be applied to a wide variety of base materials and offer long-lasting protection. They are particularly well anchored mechanically to the substrate. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance.

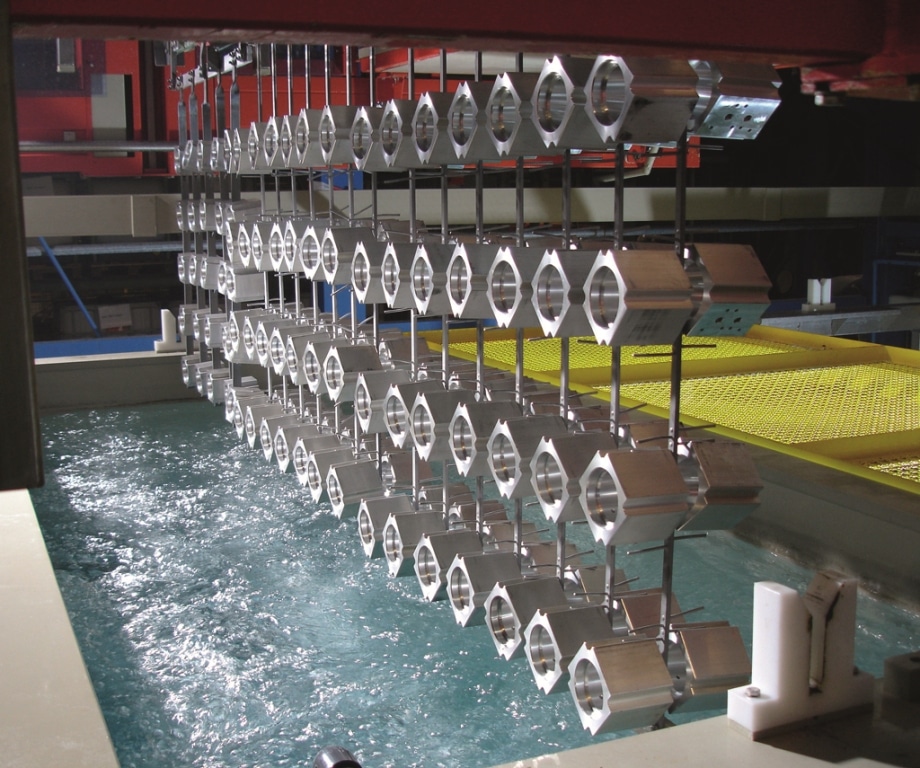

reel-to-reel

With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. Our service includes barrel plating, continuous selective plating and rack plating.

surface treatment

Almost all metallic base materials can have their properties optimised by surface coatings using our proprietary and patented processes, regardless of whether they should be particularly hard, smooth, wear-resistant or corrosion-resistant.