polymer coating

Aalberts surface technologies Lübeck

welcome to Luebeck

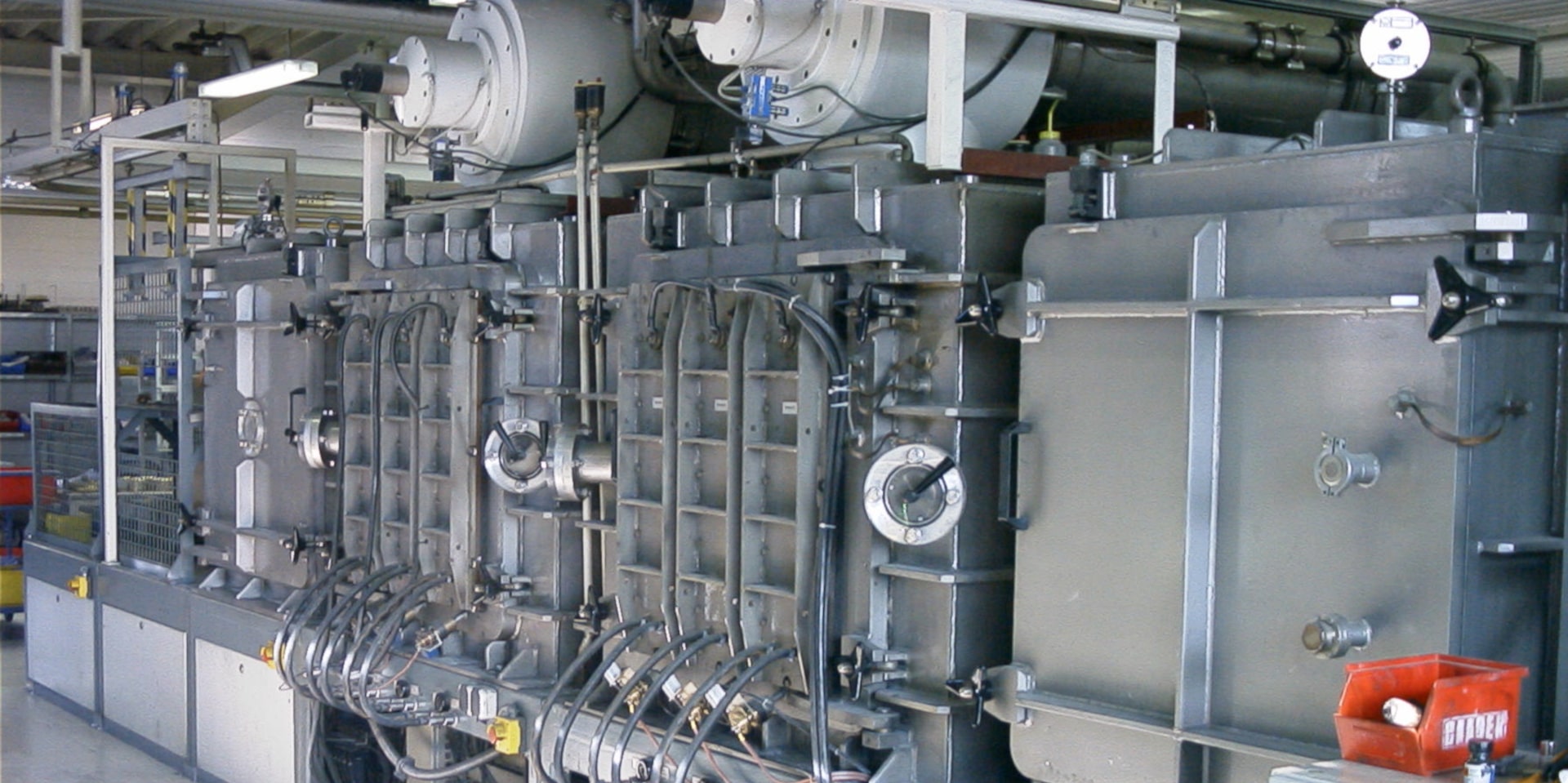

For more than 30 years, Aalberts surface technologies Luebeck has been your problem-solver in the area of surface and material technologies thanks to extremely wear-proof and low-friction vacuum plasma coatings using PVD and PACVD methods.

Our cerid® coatings extend the service life of engines, tools and machines, thereby making a key contribution towards conserving our resources and improving productivity and performance.

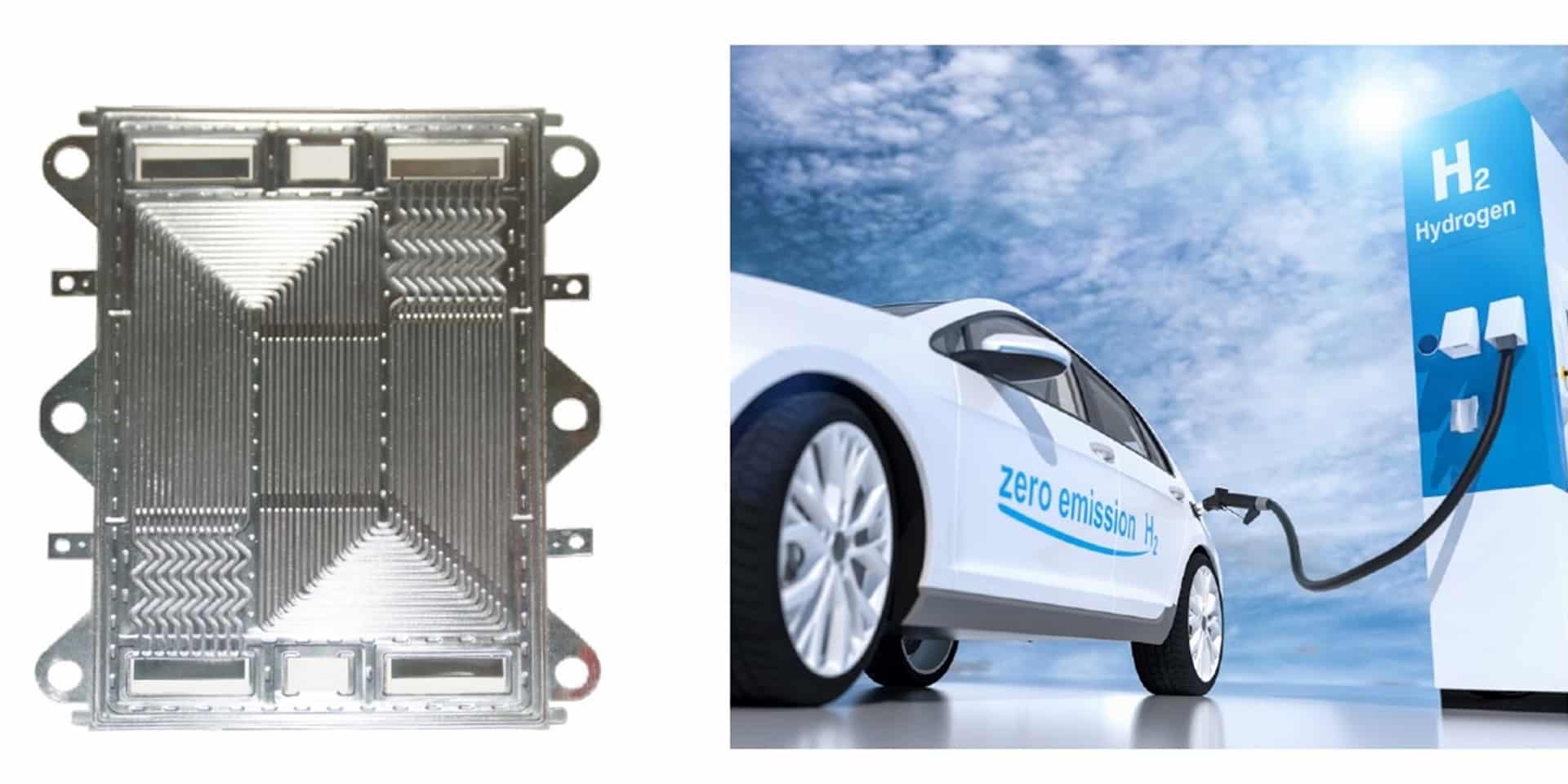

With our 4 in-line series systems, we already have sufficient capacity (5 GW) to play a key role in the energy transition in hydrogen technology. Our focus here is particularly on the coating of bipolar plates and PTL/GDL in fuel cells and electrolyzers.

In addition to coating classic industrial products, we have also been using our coatings in medical technology, e.g. on implants and surgical instruments, for over 30 years.

Our PVD chrome coatings are chrome VI-free and are an excellent replacement for electroplated hard chrome.

our services

coatings

- Precious metal layers (Pt, Au …) for hydrogen technology

- Wear protection

- Corrosion protection

- Sliding coatings

- Wear-resistant non-adhesive coatings

- Allergy reduction

- Biocompatible coatings

- Decorative coatings

process services

- PVD

- PACVD (DLC)

- Combined electroplating/PVD coatings

- Chrome VI substitute – free hard chrome replacement

special services

- High-quality analytics with customized application development

- Logistics

- Storage

- Polishing

- Sandblasting

- Assembly and disassembly

Another key application for thin films is increasing the conductivity and corrosion resistance of drive units in fuel cells and electrolysers. These “stacks” consist of several hundred individual bipolar plates with PTL/GDL nonwovens, which are exposed to extreme loads during operation.

As the preferred development and series partner of a leading German car manufacturer, we have made a decisive contribution to the development of this pioneering technology with our cerid® special layers.

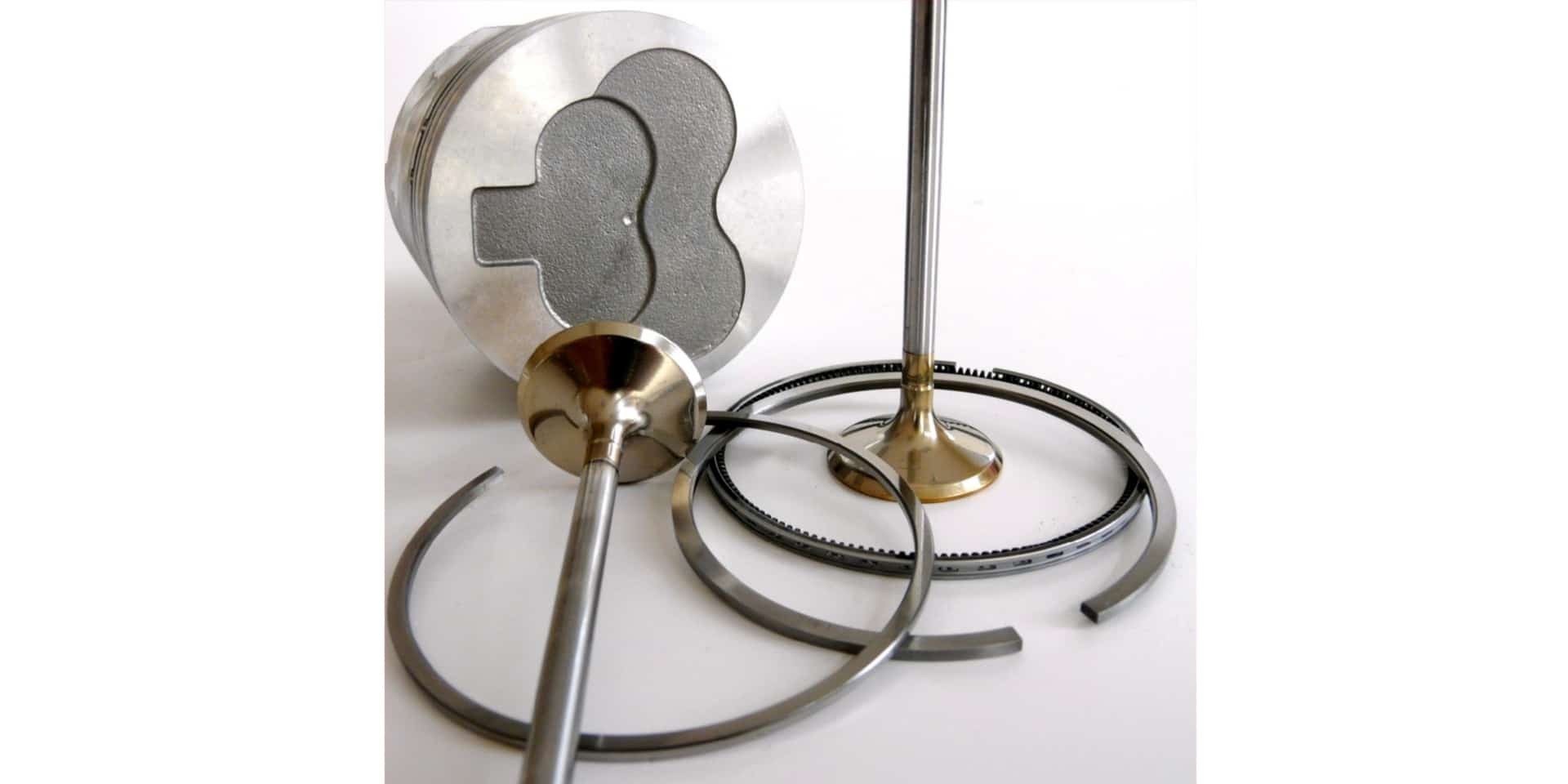

Thanks to their ceramic hardness and low coating thickness of only a few µm, our wear-resistant carbide coatings are particularly suitable as finish coatings. Typical serial applications include valve train components in car engines, for example.

Our unique in-line technology makes us a preferred partner to both automobile manufacturers and suppliers. It enables us to manufacture large PVD series very economically and with maximum reproducible quality.

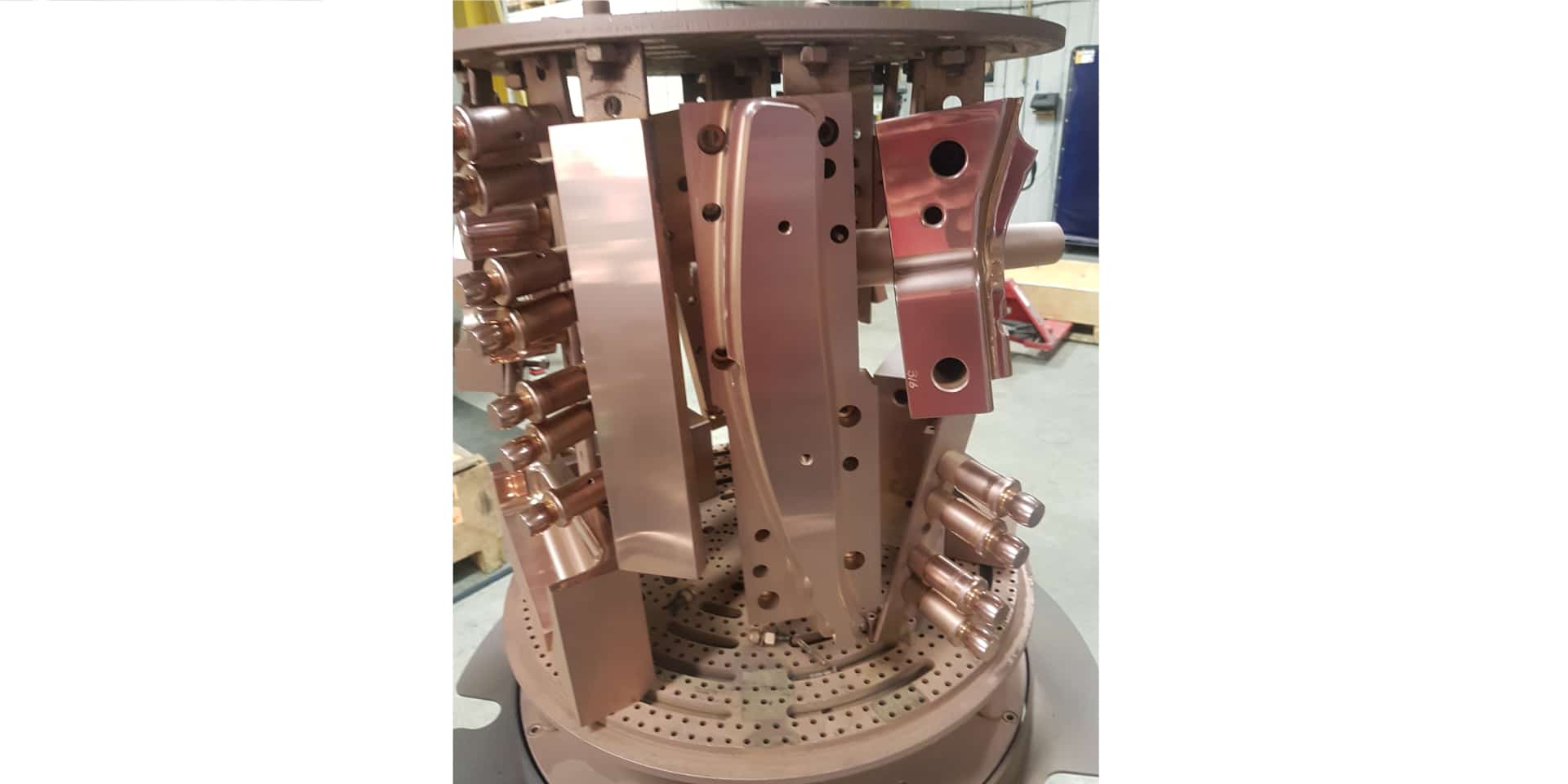

In the area of forming technology, cerid® coatings prevent galling on tools and significantly increase service lives, particularly in the area of complex stainless steel forming.

In the area of forming technology, cerid® coatings prevent galling on tools and significantly increase service lives, particularly in the area of complex stainless steel forming.

In the area of plastics processing (injection moulding / extrusion), cerid® coatings are used as wear protection and as non-adhesive finishes to prevent adhesion.

We have developed special low-friction coatings which display extraordinary anti-adhesion properties and yet very high degrees of wear resistance. They are used, e.g. on calibration parts in PVC extrusion or on tools in the area of plastics processing.

Using a combination of electroplated coatings and PVD, practically pore-free corrosion-protective surfaces can be achieved on components and tools. These are used in the plastics industry, for example, when halogenated fillers are used as fire retardants (aerospace). With coating systems like these, practically gas-proof tool protective coatings can be achieved (PTFE extrusion).

With our various DLC coating variants, manufactured using both PVD and PACVD, friction coefficients of µ < 0.1 can be achieved towards steel. DLC coatings are often used as decorative non-scratch surface finishes (colour: anthracite).

In the medical technology sector and especially in the area of implantology, biocompatible coatings are attributed great significance. The success of the healing process following the insertion of implants into the biological system is decisively influenced by the biocompatibility of the implants themselves – particularly their surface finishes – as well as their durability, i.e. their long-term stability inside the body.

Working with institutes and experienced implantologists, Aalberts surface technologies has dedicated resources to these topics and developed biocompatible coatings which have proved their value in clinical applications for more than 20 years.

quality and know-how

applications

For more than 30 years, we have been developing coatings for the surface finishes of a wide variety of applications and sectors which significantly increase the efficiency and service life of components and tools. Using the experience offered by our experts and the possibilities afforded us by our own in-house material analysis, we develop the optimal solution for any customer. Our manifold plant technologies enable us to implement such solutions, whether they involve individual pieces or large-volume series. We avail of many years of experience in dealing with the high demands of the automotive industry, aerospace and medical technology.

areas of application

downloads

Aalberts surface technologies offers security. We want to offer you the greatest possible security. That is why our Aalberts surface technologies sites are certified.

certificates

We are certified to DIN EN ISO 9001:2015, DIN EN ISO 13485:2016 and VDA 6.1:2016.

general terms and conditions

our inhouse processes

We are the right partner for coating processes like vacuum coatings or electroplating. Our competence also includes partial coating of components and keeping technically necessary areas of the components free from coating.

industries we serve

contact & directions

Aalberts Surface Technologies GmbH