surface technologies for medical devices

creating the perfect solution for medical devices

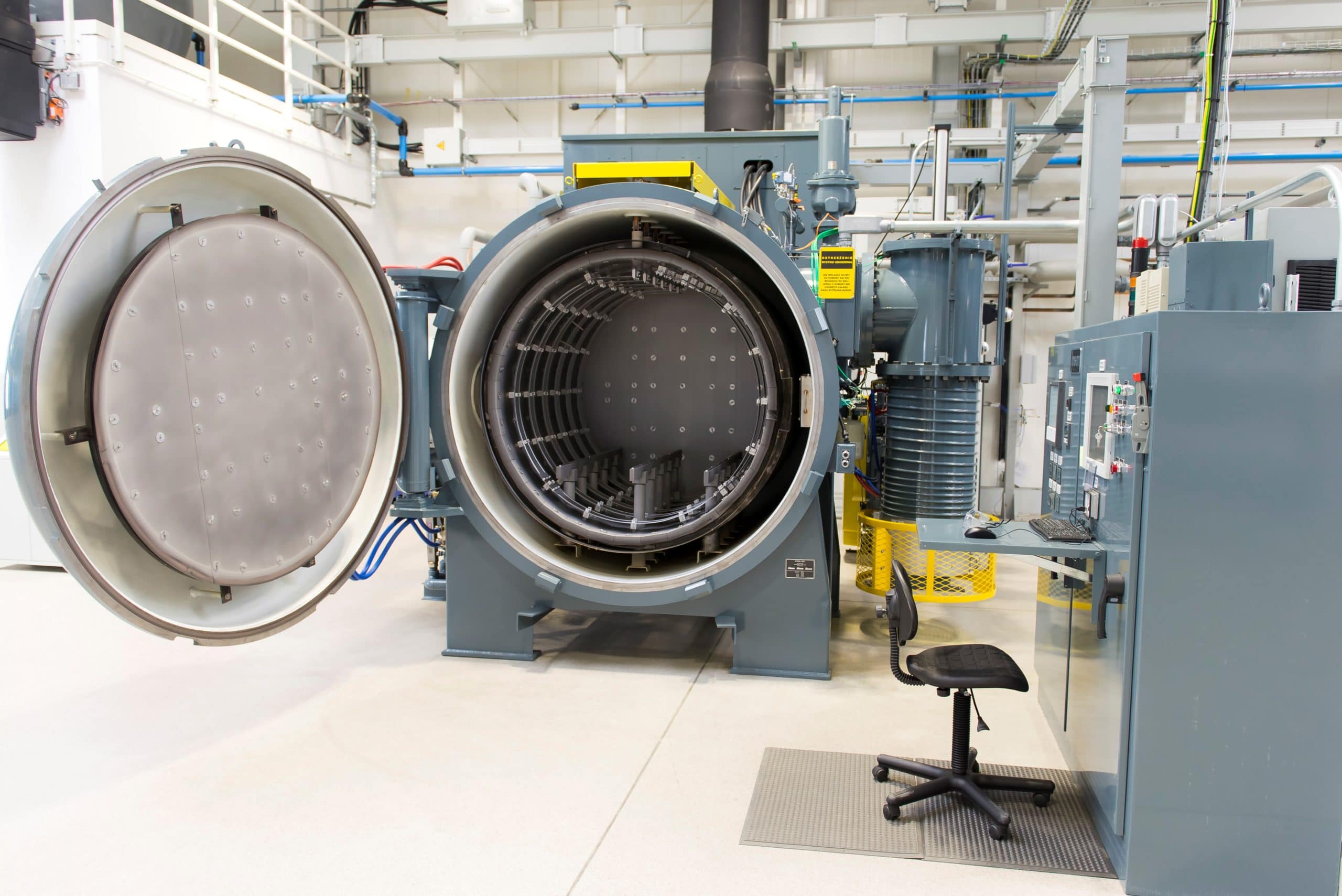

Every day, medical and healthcare professionals work to protect the health and lives of their fellow human beings. But when doing so, they need to be able to rely fully on their medical equipment and instruments. High-quality industrial hardening, vacuum brazing and coatings play a key role in ensuring that this requirement is met.

Our innovative technologies are vitally important in preserving the sterility of implants, medical instruments and components for medical systems, helping healthcare professionals comply with the strictest hygiene standards.

quality in every respect

Modern medical technology sets the highest standards for tribology, durability and biocompatibility, as well as for the degree of purity of coated medical devices. At Aalberts surface technologies, we also fulfil highly complex customer requirements and specialize in the functional refinement of components for medical technology systems, and products for orthopaedic and surgical applications.

High-quality solutions applied to the surfaces of medical instruments and devices prevent the formation of harmful germs. To achieve this, the following properties are indispensable:

- because it is easier for dirt to stick to uneven surfaces, the surface structure must be virtually free from pores and extremely smooth.

- soiling can be removed easily and without leaving any residues when the surface possesses non-stick properties.

- extremely hard and scratch-resistant surfaces help maintain the properties for longer.

- efficient corrosion protection increases the longevity of components.

- as medical devices need to be sterilized with corrosive substances, it is imperative that the surface is highly resistant to aggressive chemicals.

- the surface coating must securely adhere to the substrate.

In medical technology, aluminum has a very high utility value as a basic material or alloy, due to its low weight. During anodizing and hard anodizing, the surface finish grows into the workpiece. Despite the low process temperatures, these processes – which occur with precisely defined dimensional changes – create extremely strong bonding forces between the surface finish and the basic material.

HART-COAT®, our hard-anodized coating characterized by extremely fine pores, offers exceptionally high durability, excellent resistance to corrosion, and hardness values of up to 480 HV0.025.

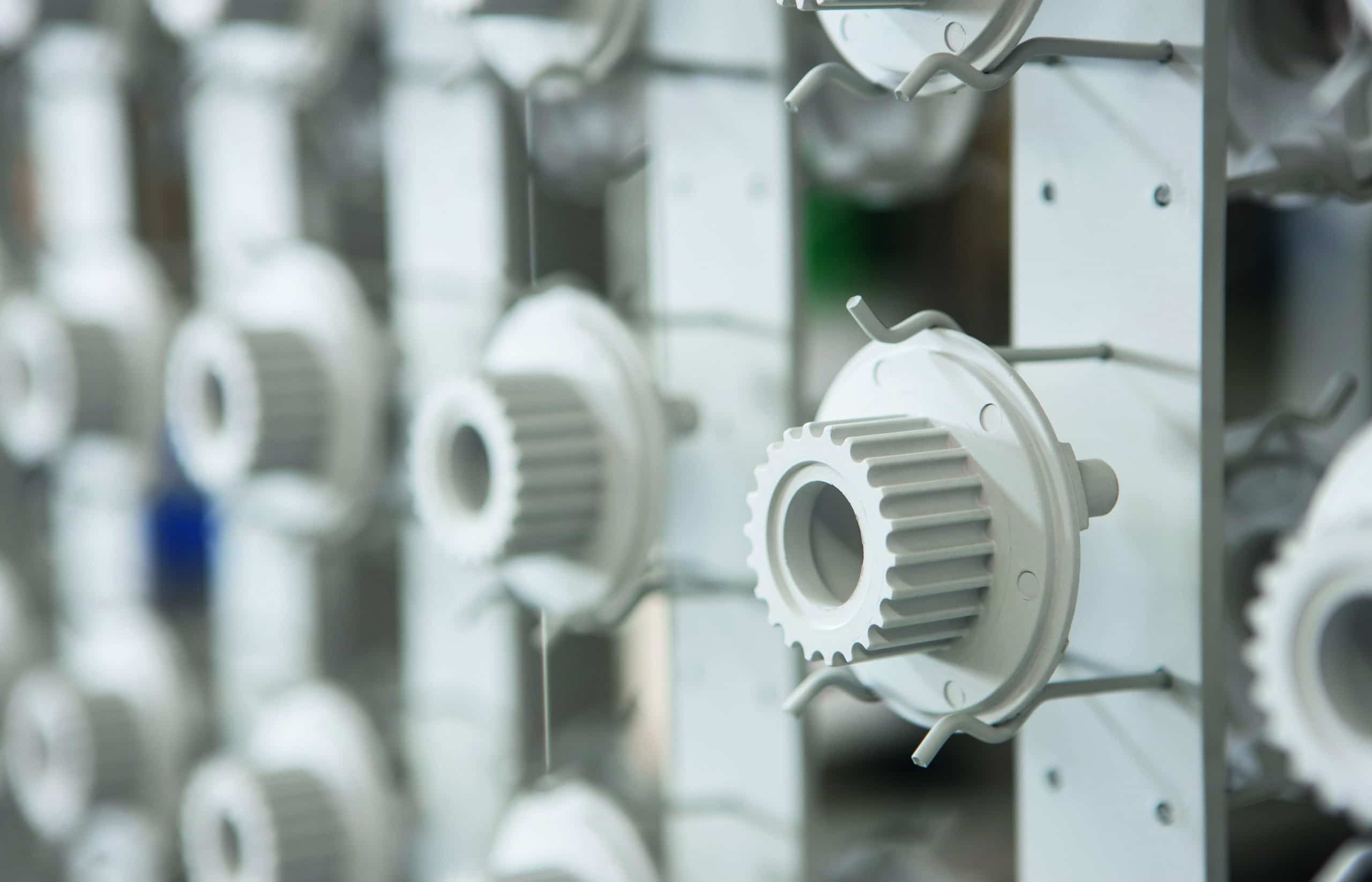

HART-COAT® is used in a range of applications, including to coat fixed-angle rotors of microliter centrifuges. These devices can be found in blood banks and clinical laboratories, where blood and other bodily fluids are centrifuged. In the research area, these centrifuges are used for the extraction of DNA, proteins and enzymes. For weight reduction purposes, fixed-angle rotors are manufactured from aluminum alloys. With a thickness of 40 µm, this hard-anodized layer protects components against corrosion.

Pre-treatment with our SILA-COAT® dip coating ensures more than 1,000 hours of corrosion resistance in the salt spray test. The dielectric strength exceeds that of most hard-anodized layers.

When combining SILA-COAT® with an anodized layer, it is possible to create an extremely resistant surface finish, which is able to withstand acidic and alkaline cleaners in around 1,000 cleaning cycles.

One example is sterile packaging, such as implant and instrument containers. While the container frame consists of plastic, the housing, the inserts and the plates are made from aluminum alloy. In this case, resistance to alkaline cleaning media is more important than resistance to wear and tear.

When it comes to the surface coating of medical devices, we go even further by using our own patents and high-performance processes:

- Plasma-chemical finishing of magnesium and aluminum materials

- Chemical nickel plating of ferrous and non-ferrous materials, which are ideal for combined coatings involving PVD

we know our customers’ needs

We want our customers’ projects to run smoothly, which is why we adapt our concept to your requirements. With almost 60 years’ research and experience into surface technologies and providing professional advice, we are dedicated to finding a solution to your problems. And with branch offices from Europe to Shanghai to Chicago, we are always close by.

applicable processes

relevant process locations

get in touch

Select your preferred process location or contact us directly.