quick and error-free results

the importance of packaging to the industry

Effective packaging is crucial. It protects the product and promotes sales. But to present their products in an attractive way, companies are often forced to spend more on the packaging than the actual product.

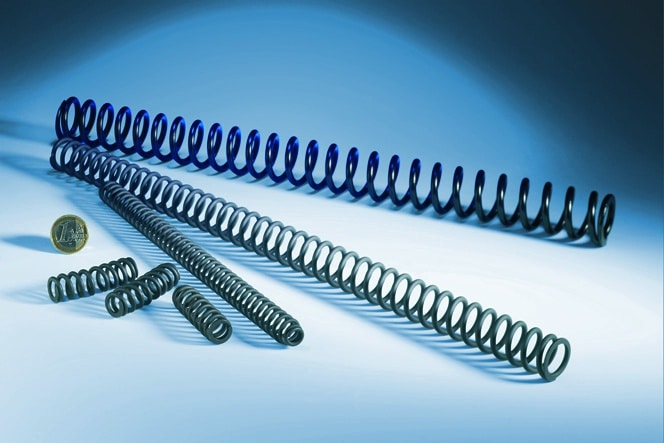

We have a solution to help the industry: surface technologies. Our hardening and coatings optimize packaging machines’ durability and create the conditions required for higher speeds, which improves efficiency and leads to smoother packaging processes.

benefits of packaging industry

Backed by years of experience in the packaging industry, we provide technologies that are optimized by wear-resistant, non-stick and anti-friction properties. This enables us to provide you with a number of key economic improvements:

- Avoid malfunctions and downtime caused by the formation of product, film and adhesive deposits

- The reduction of worn parts means fewer replacements

- Increased machine speed through reduced frictional resistance

- Adhesions and decelerations of bulk material in slides, funnels, trays and scale pans are reduced, meaning filling weights can be perfectly observed without “loss reserves”

- Cleaning and standstill periods are reduced thanks to easy-to-clean surfaces.

- And of course, corrosion resistant

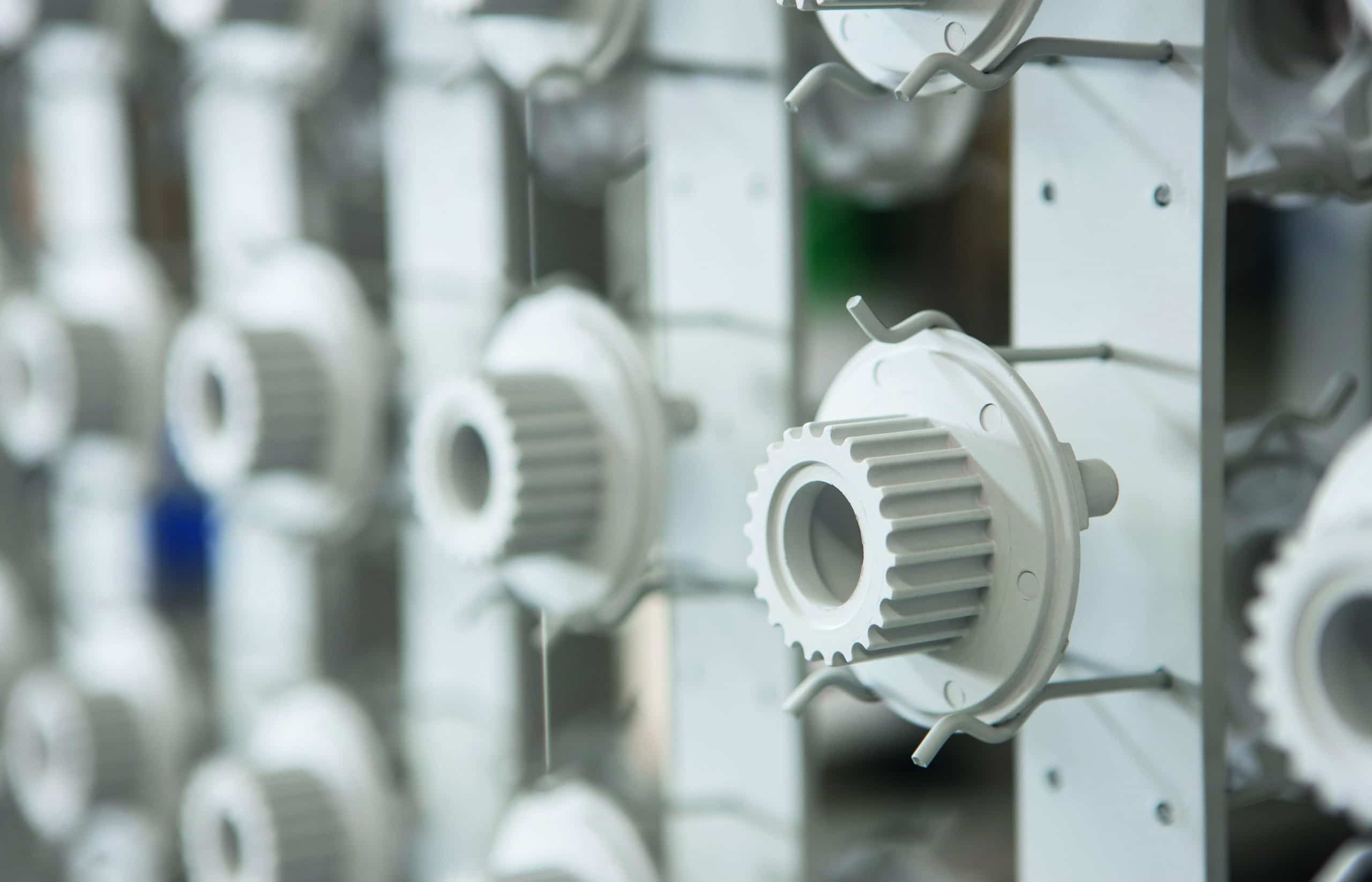

To satisfy their customers, the packaging industry needs to produce quickly and accurately. And we know that the quality of the production equipment is often the decisive factor. Which is why we currently provide the industry with more than ten of our partially patented surface technologies, ensuring we have a premium solutions for every application.

The production of cardboard boxes involves punching the unprocessed cardboard into the desired shape. After adhesive has been applied to the edges of the box, it is placed onto a transport device for further processing. Frequently, the cardboard boxes become stuck in the blunt metal rails of the transport device, particularly when there is a buildup of adhesive and residues from the punching process. The result: constant cleaning and reduced production speeds, meaning fewer boxes are produced.

By coating the conveying tracks with our PlasmaCoat® anti-friction coating, the production speed can be increased significantly. Thanks to improved anti-friction properties, the cardboard boxes will no longer get caught in the tracks, meaning the machines don’t need to be stopped and regular cleaning isn’t required. The result? Lower production costs.

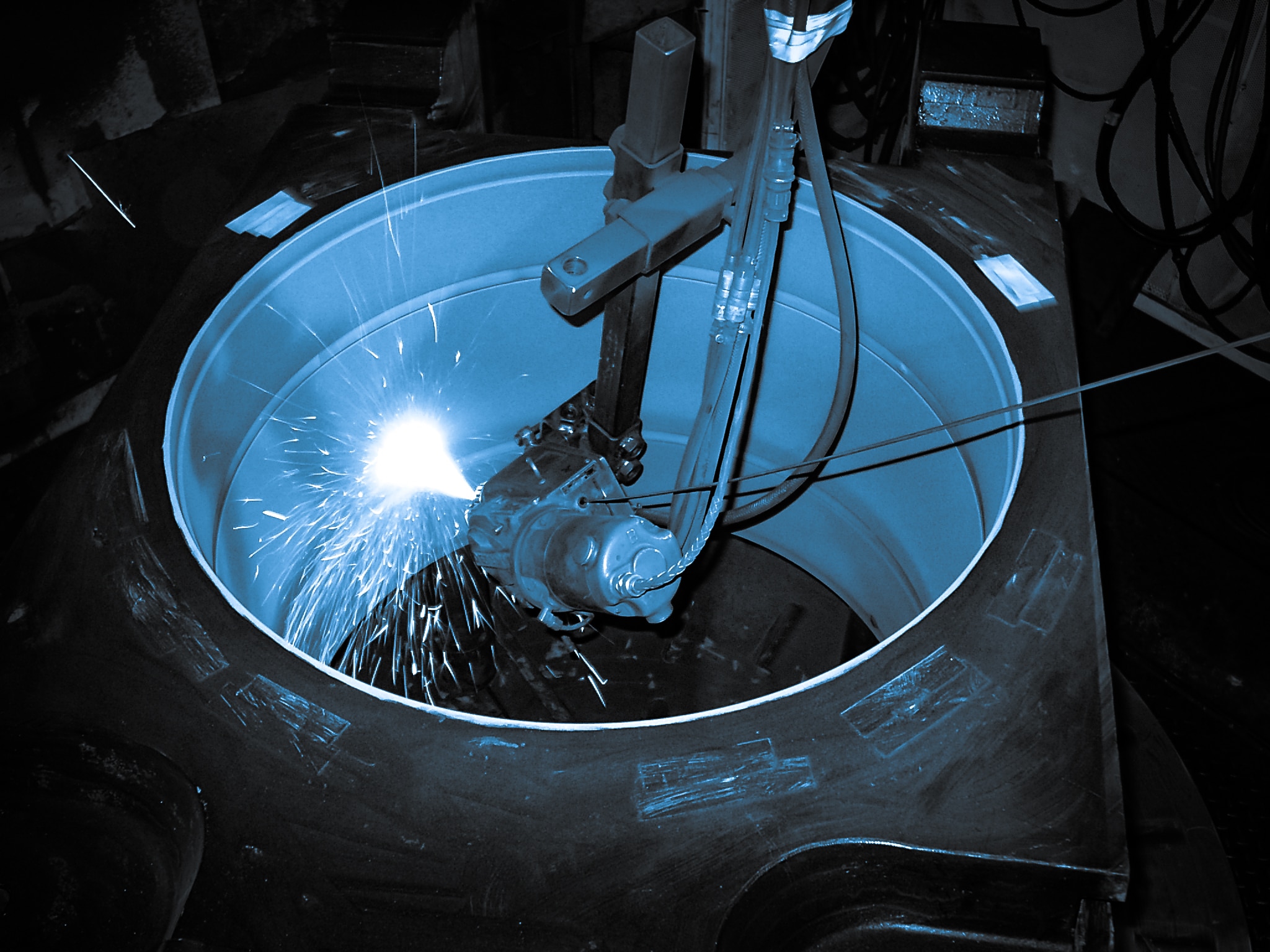

PlasmaCoat® combined coatings offer excellent wear protection for welding bars. Protection is guaranteed even at high temperatures. The coating’s excellent non-stick properties are another advantage, for example when it comes to sealing PE bags.

We develop complex and unique industrial services, helping more than 200 customers within the packaging industry and many thousands of others across a wide range of industries. And we do it globally, from our operations across three continents. We are your technologies partner.

process locations

get in touch

Select your preferred process location or contact us directly.