resistance in harsh environments

increased performance, sophisticated surface technologies

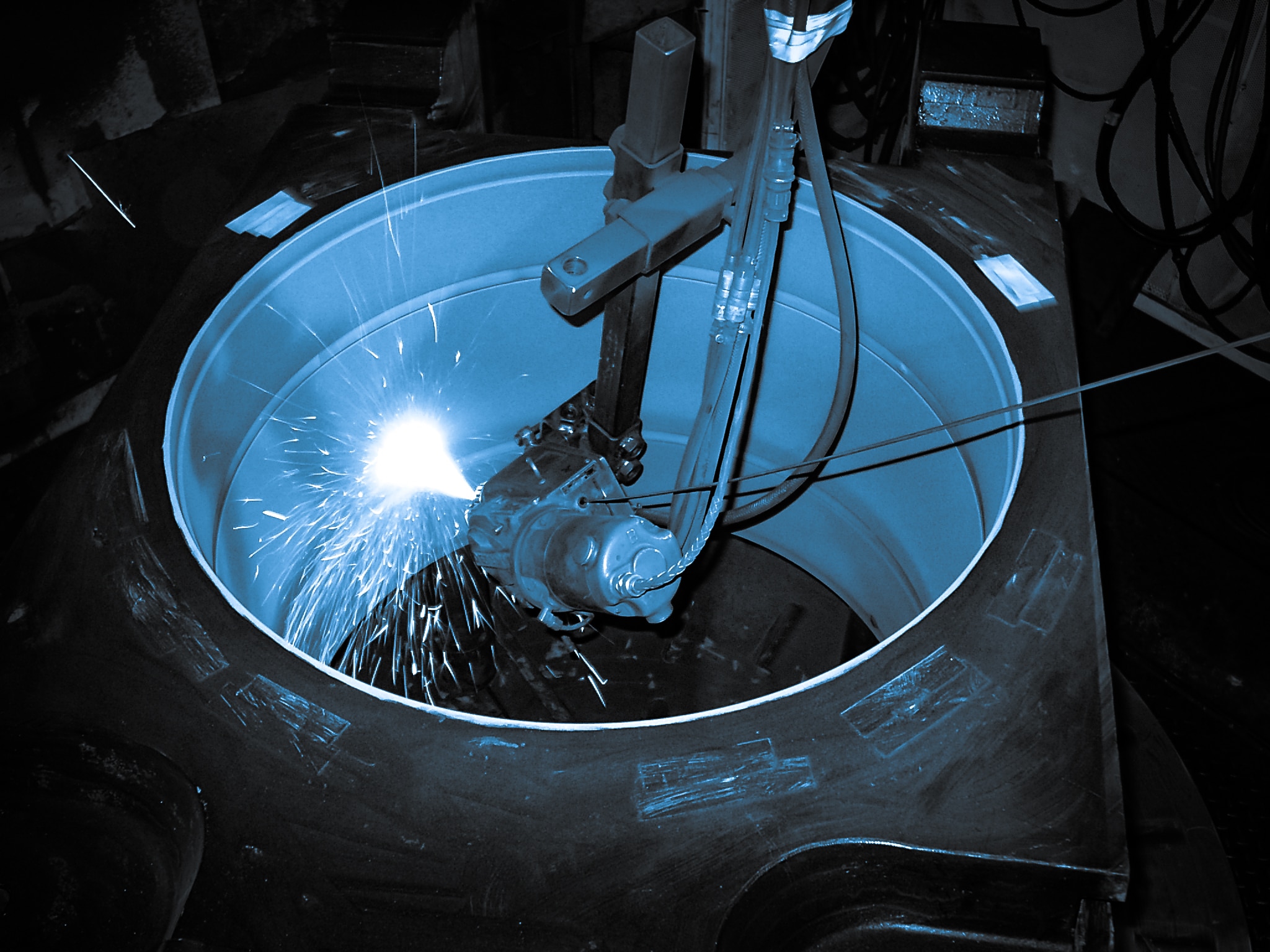

The oil and gas industry. Machines operating under challenging conditions day after day; parts subject to strong chemical and galvanic corrosion; extreme wear and tear and massive abrasion.

We understand the harsh environments the fossil fuel industry operates in, and our heat and surface treatments are designed to protect your equipment in the field, leading to long-lasting, efficient processing.

benefits of oil and gas

for nearly 60 years, we have helped provide the oil and gas industry with solutions that offer:

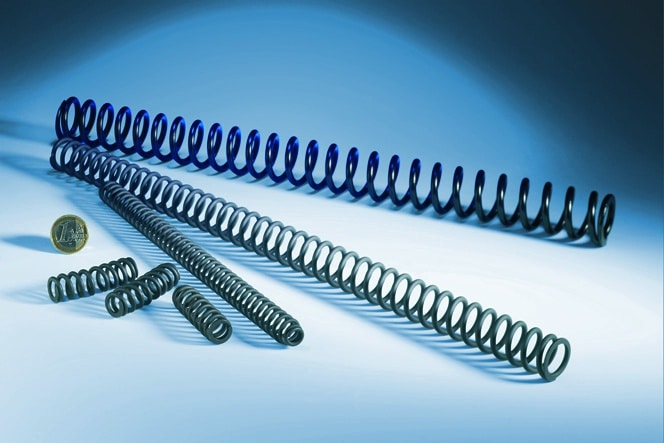

- High wear resistance

- Extreme corrosion protection

- Strong resistance to chemicals

- High temperature resistance

we have a solution for any requirement

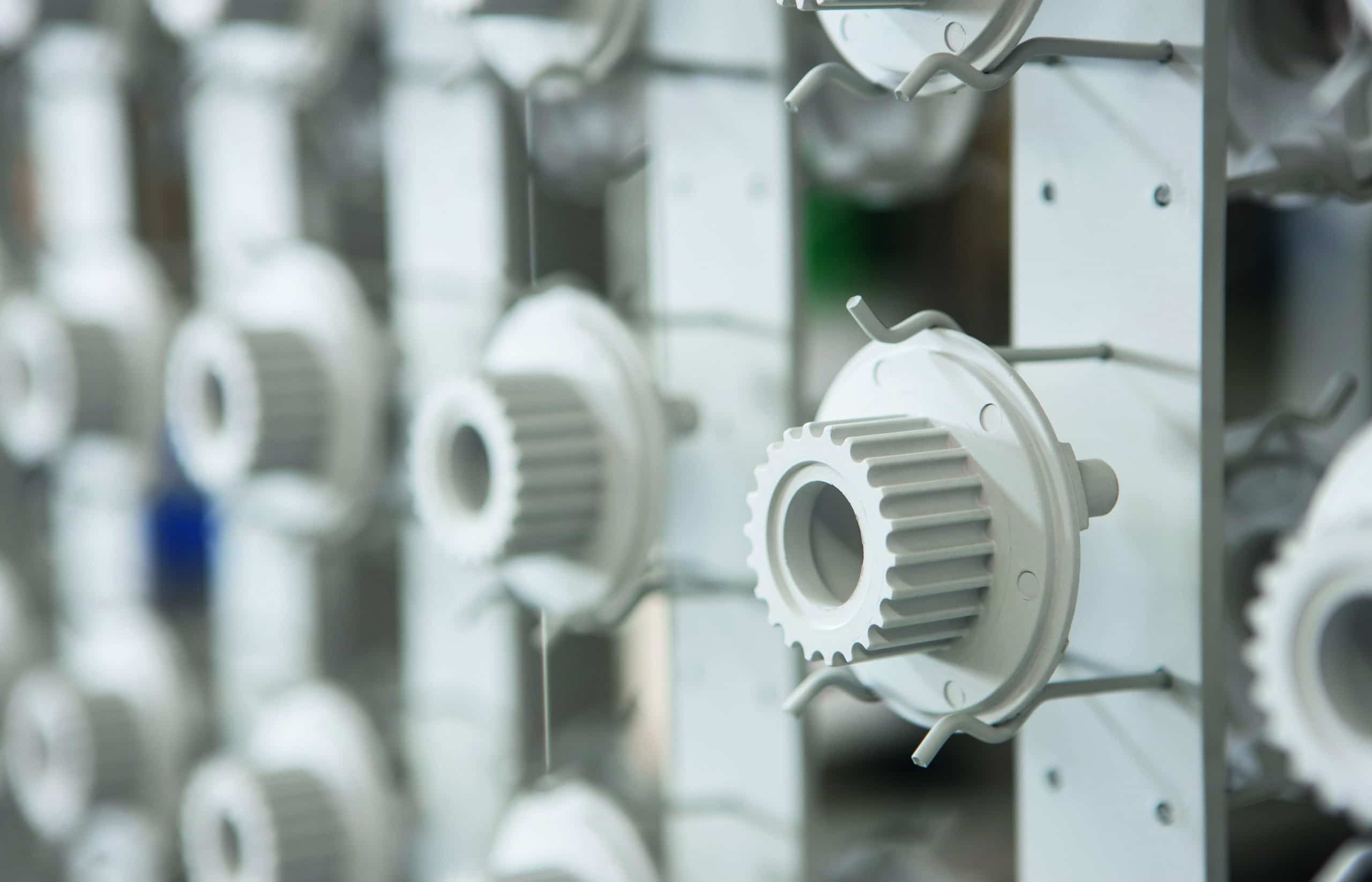

We develop innovative, premium-class solutions, such as our Stainihard® or Nitrotec®, ensuring that whatever your requirements, we have the solution. Other examples include:

- DURNI-COAT® 471

Aalberts surface technologies finished the valve housing shown on the front left-hand side with electroless nickel plating. The pump, which is used to transport aggressive waters, was made more resistant to corrosion and wear.

- TUFRAM®

This coating creates a steely, self-lubricating plastic-ceramic surface infused with polymer particles. It is used to increase the components resistance to seawater

The oil and gas industry are constantly looking to increase performance and efficiency for the machinery they depend on most. Austempered materials have a proven track record of providing strength, durability, and dependability for the critical applications within the oil and gas industry.

process locations

get in touch

Select your preferred process location or contact us directly.