e-mobility

providing process solutions

E-mobility is the new mobility, with electric cars, e-bikes and e-scooters becoming increasingly important across society. For manufacturers, this creates new challenges in the supply chain: from hybrid technology, lightweight construction solutions, advanced safety systems and autonomous driving, through to influences on acoustics and the service life of vehicles.

Yet when most of us think of e-mobility, we think of battery and fuel-cell technology for alternative drive systems. Yet that’s only part of the story. Heat and Surface finishing also plays a vital role, with innovative technologies able to optimise many key areas. And in a rapidly changing market, flexibility is key, as many of these new requirements can be met by selecting the right treatment systems.

benefits

acoustics in e-mobility

Vehicle acoustics deals with the modeling of sounds – both inside the vehicle and those heard outside the vehicle. For a vehicle’s occupants, the focus is on noise reduction. While outside the vehicle, the focus is on safety: because e-vehicles don’t produce the same noise as a combustion engine, the focus switches to the acoustics of the electric drive train and operating noise.

This means that developing e-vehicles involves meeting both the emotional needs of customers, and reducing movement and vibration noise in a targeted manner.

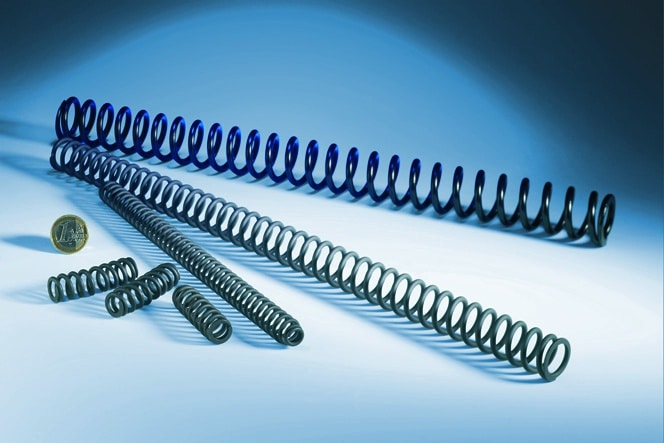

To cut vibration noise, we provide customers with a range of specialised products. These include dry-lubricating bonded coatings in the form of polymer systems based on PTFE, PFA or FEP fluoropolymers, as well as MoS2 or graphite. Well-known systems include Xylan®, Molykote®, Gleitmo®, Antifricor® and GLISS-COAT®.

We help customers reduce contact noises caused by vibration, by using flock coating with cathodic dip coating (KTL) as the base layer. Further advantages of the pure flock coating are the compensation of manufacturing tolerances, and noise insulation on metal and plastic surfaces.

electrification

Electric vehicles are not only powered by electricity, they are also equipped with a variety of on-board electrical systems. While this improves performance and comfort, it also significantly increases power consumption. This means that the 12 volts used in combustion engine vehicles are no longer sufficient for electric cars onboard systems, which is why we have seen a recent shift 48-volt technology.

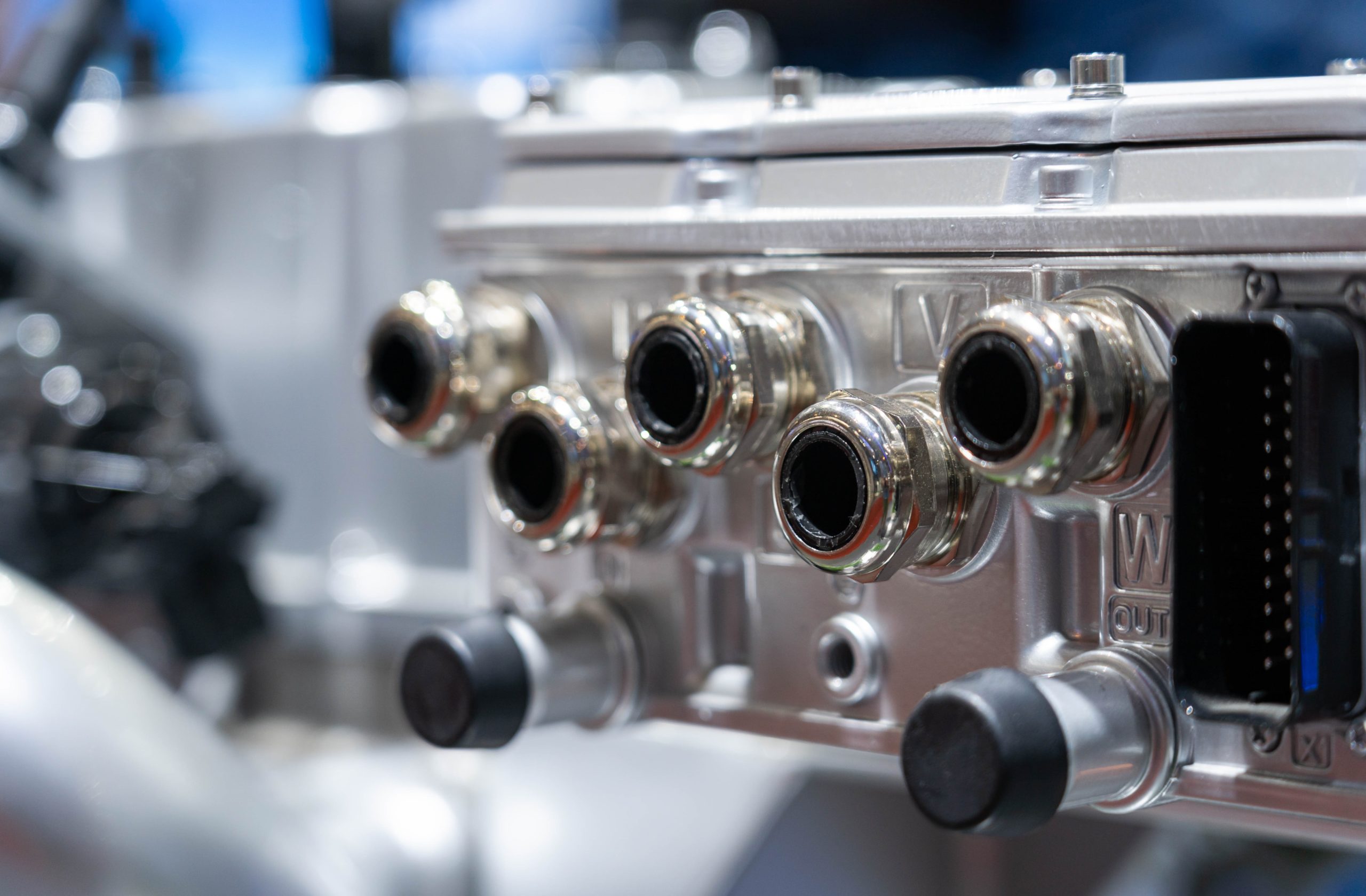

The basic requirement for good electrical conductivity is high-quality contacts or connectors and busbars, ideally coated with tin, silver or gold. The best option is to choose combination layers with a diffusion barrier of copper and nickel, since these ensure good corrosion protection and good signal and current transmission.

However, when using 48 volts, the operating temperature of the fasteners rises to over 160°C, meaning that for safe operations silver coatings in higher layer thicknesses must be deposited on the components.

A professional coating is also crucial for the safe operation of large vehicle batteries, because efficient protective devices, such as corrosion-protected battery housings, can only be created with high-quality surface technology.

Nickel plating with sulfamate nickel offers the advantage of solderability and weldability in addition to high-coating thicknesses and a good adhesion base for combination coatings. In addition, investigations are currently underway to replace the graphite layer on the anodes of lithium-ion batteries with a tin layer and thus achieve a significant reduction in costs.

A frequently neglected aspect connected to electrification is the transmission of high-frequency signals in the vehicle. For these to run without interference, good contacting and an effective reduction of interference sources are required. A multi-layer structure allows static charges on hard-anodized aluminum surfaces to be selectively dissipated and signal transmission interference to be reduced, while also providing electrical insulation.

Due to their high conductivity, silver-plated or tin-plated connectors are also indispensable for future standards, such as autonomous driving or sensor-based hazard detection. Coating technology thus creates the basis for the safe operation of the on-board systems of the future.

lightweight construction

The Achilles heel of many of today’s electric vehicles is their low range. One way manufacturers is aiming to combat this is to use lighter construction materials. In addition to aluminum and high-strength steel, higher-quality materials such as titanium and magnesium are increasingly used for this purpose. Heat treatment, which improves the strength and stiffness, is absolutely necessary. And these materials have to be coated correctly.

For example, magnesium rims need a magnesium oxide coating for corrosion protection and to prepare them for wet paint or powder coating. High-strength steel can be used with very thin walls, but this leaves them susceptible to corrosion damage, which can be protected against using effective coating. And for titanium, galvanic corrosion with other metallic materials, which can occur despite the formation of a passive layer, can be prevented by applying an oxide coating.

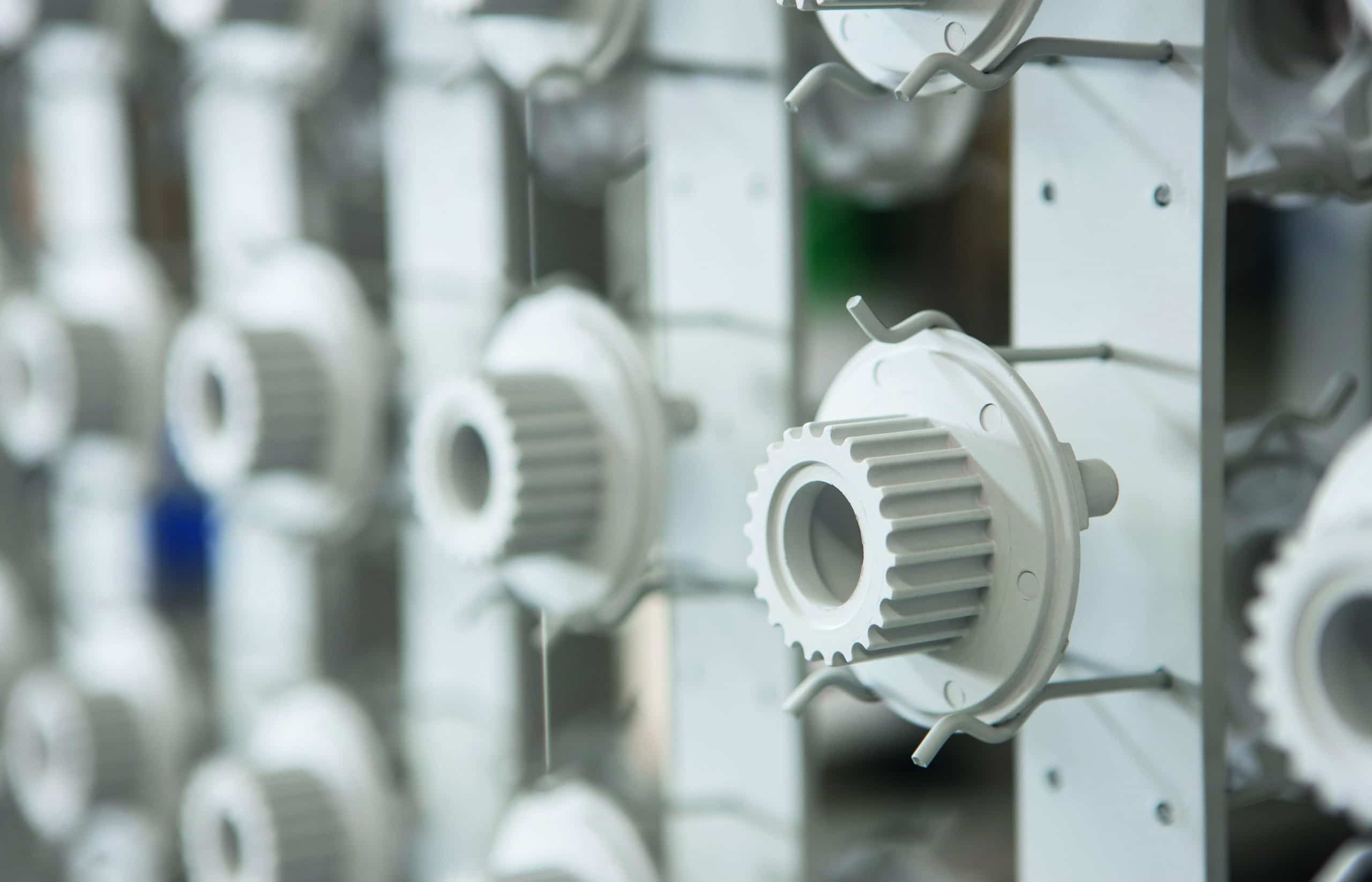

In e-bikes, manufacturers typically use aluminum and magnesium to save weight. For example, an aluminum oxide coating on battery housings creates a primer for adhesives – as a common alternative to welded joints – and magnesium coatings provide improved wear protection, for example on gear wheels.

service life and the price structure of components

As we shift to electric vehicles, one focal area is the adjustment of components service life. In principle, electric vehicles can be used for longer because they suffer less wear and tear than combustion vehicles, and contain fewer components. At the same time, consumers expect the vehicles to have a longer service life because of their higher purchase price.

As the industry develops, the focus in the future will be on new assembly methods and increased corrosion protection classes for chassis components. In those areas where low corrosion protection classes are currently sufficient, he focus will shift to heat treatment of high-strength steels (Stainihard®, Nitrotec ®), higher quality microlayer corrosion protection systems (zinc flake coatings) or electroplated nickel (sulfamate nickel) and electroless nickel (DURNI-COAT®). This will make the professional heat treatments and coating of a wide range of components even more crucial across the automotive industry.

relevant process locations

get in touch

Select your preferred process location or contact us directly.