creating specialist treatments for the printing industry

we focus on economic efficiency

In an increasingly digitalized world, the printing industry is becoming more dependent on economic process optimization. And while many end-consumers still prefer to hold a newspaper or book in their hands, the final price needs to be close to that of the digital equivalent. Applying the right technologies can considerably increase the economic efficiency in the printing industry, helping to ensure your company’s continuing competitiveness. And this is where we can help.

benefits for the printing industry

special challenges during the printing process

Paper processing at high speeds generates considerable forces, which might even impact machine components made of steel. For example, the dust generated by the paper leaves soiling on the machine components, and the set web tension gets lost.

Dried bookbinding adhesive residues and inks remain stuck to the containers and rollers. The result? Extensive cleaning and machine downtime. And over the long term, removing particularly stubborn residues can result in damage to the machine.

All these factors can influence trouble-free, smoothly running production.

the patented solution: extremely heavy-duty solutions

To avoid ink traces, maintain the web tension without damaging the material and ensure resistance to dust, you need material surfaces capable of fulfilling different requirements at the same time.

High resistance to wear and excellent non-stick properties characterizes the technologies we provide customers within the printing industry.

We use high-quality polymer and fluoropolymer finishes, in conjunction with functional intermediate layers, for our highly effective and partially patented surface finishes. And before that, our heat treatments come into play

Our applications offer the following key characteristics:

- Excellent wear resistance

- Low degree of roughening

- Firm bonding with the base material

- Outstanding non-stick properties

- Durable anti-corrosion coating

- Excellent sliding properties

customized systems: special solutions

Within printing, certain areas of the production process become more economical when using optimized surface and increasing the machine run time.

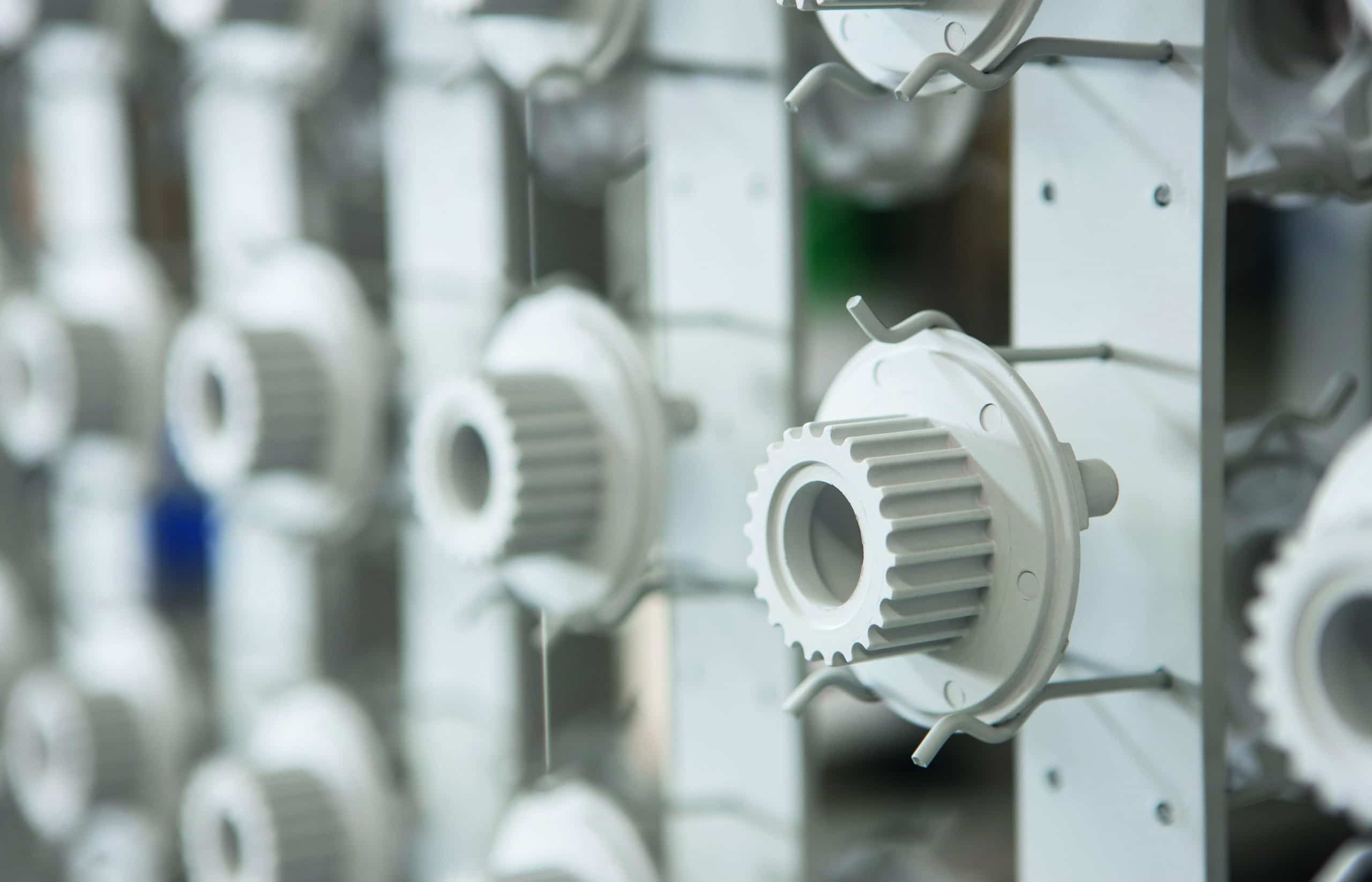

Most modern-day bookbinding machines use strong PUR adhesives to glue together the spines. The adhesive in the glue pot is heated to the required processing temperature and then applied to the spines using several application rollers.

Once the day’s production has been completed, the adhesive cools down and hardens. Valuable working time is lost due to the extensive cleaning of glue pots and application rollers which, in the end, also get damaged by the daily cleaning processes.

Our TempCoat® and MagnaCoat® (formerly known as ChemCoat® and SafeCoat®) coatings improve the non-stick properties of glue pots and application rollers significantly. All you have to do is peel off the cooled adhesive residues, reducing required cleaning and machine downtime. You will also avoid damage to the application rollers and glue pots.

Ink trays are an integral part of the printing industry. They are used continuously, and whenever the ink needs to be changed, the ink residues must be removed from the trays and containers swiftly so that the next print job can be started.

The use of TempCoat® (formerly known as ChemCoat®) for surface coatings in the printing industry ensures that dried ink residues do not stick to the surfaces. This means they can be easily removed. The result? Less cleaning time, more production time. And no damage caused by scratching off any dried ink residues.

When labels are printed, punch cylinders are used to punch different shapes and sizes out of the web. During the punching process, the anvil cylinder’s blades repeatedly push onto the punch cylinder’s metal surface.

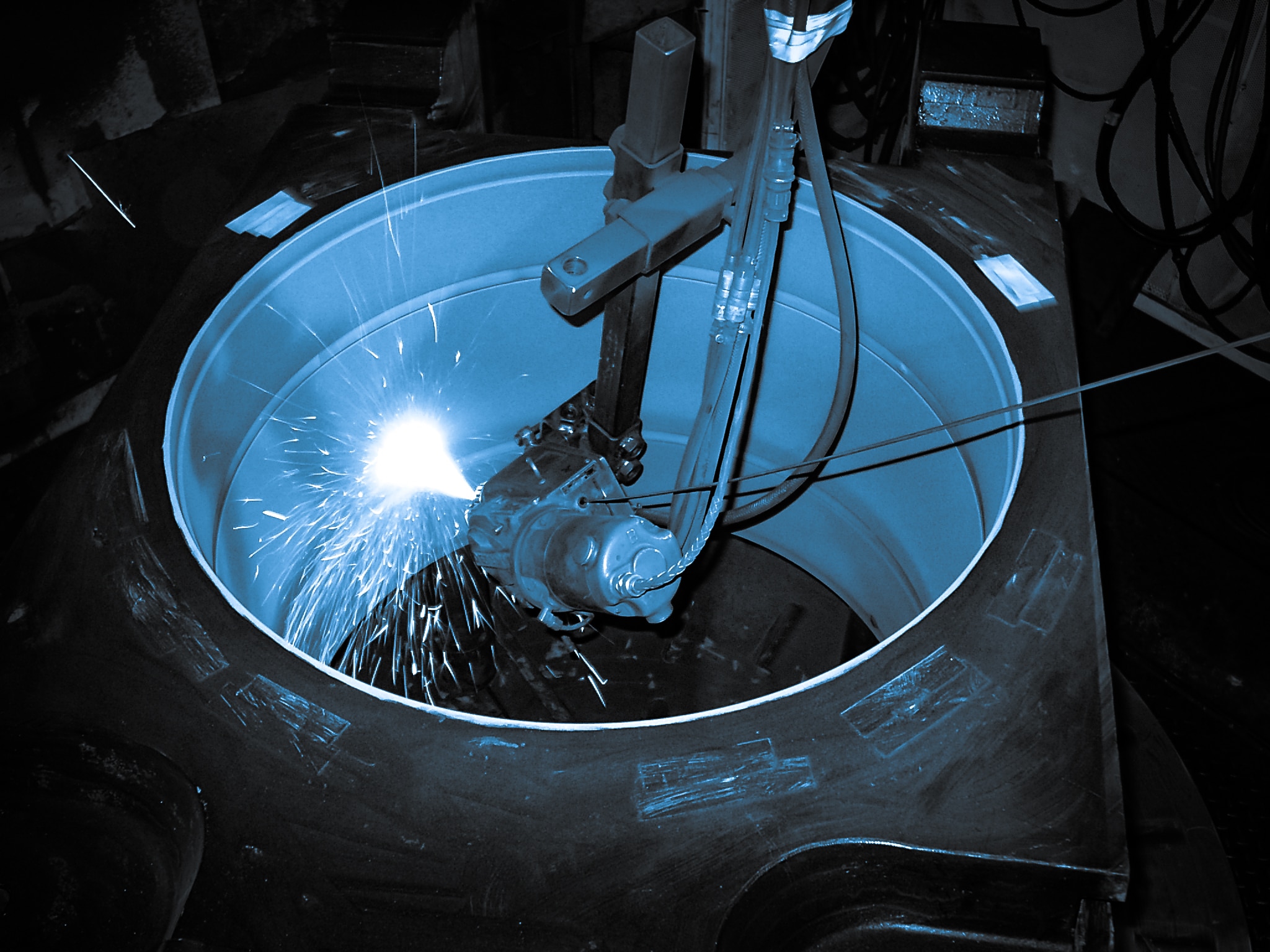

As well as the cutting knives becoming blunt over time, the surface of the punch cylinder can also get damaged. An extremely hard type of coating, StarCoat®, offers excellent wear protection. Both the punch cylinders and the anvil cylinders are thus protected against damage and wear. To create a layer with durable wear protection, StarCoat® metal and carbide coatings are applied to the surface using high-speed thermal spraying processes. This application method results in increased productivity thanks to a larger number of punching operations. Which means no premature repairs or new acquisitions.

surface technologies solutions: available globally

We develop complex and unique industrial services, helping thousands of customers across a wide range of industries. And we do it globally, from our operations across three continents. We are your technologies partner.

process locations

get in touch

Select your preferred process location or contact us directly.