tool manufacturing

tool and mold industry

Critical tolerances and precise dimensions are parameters which are very important in the tool and mold industry. Our versatile system and processing technologies coupled with our consistent quality management make Aalberts surface technologies a very strong partner for many companies in the field of tooling. We use our long-standing expertise to provide optimal care to your products and to reach an optimal end result. Moreover, we offer an optimal support throughout all phases of your project.

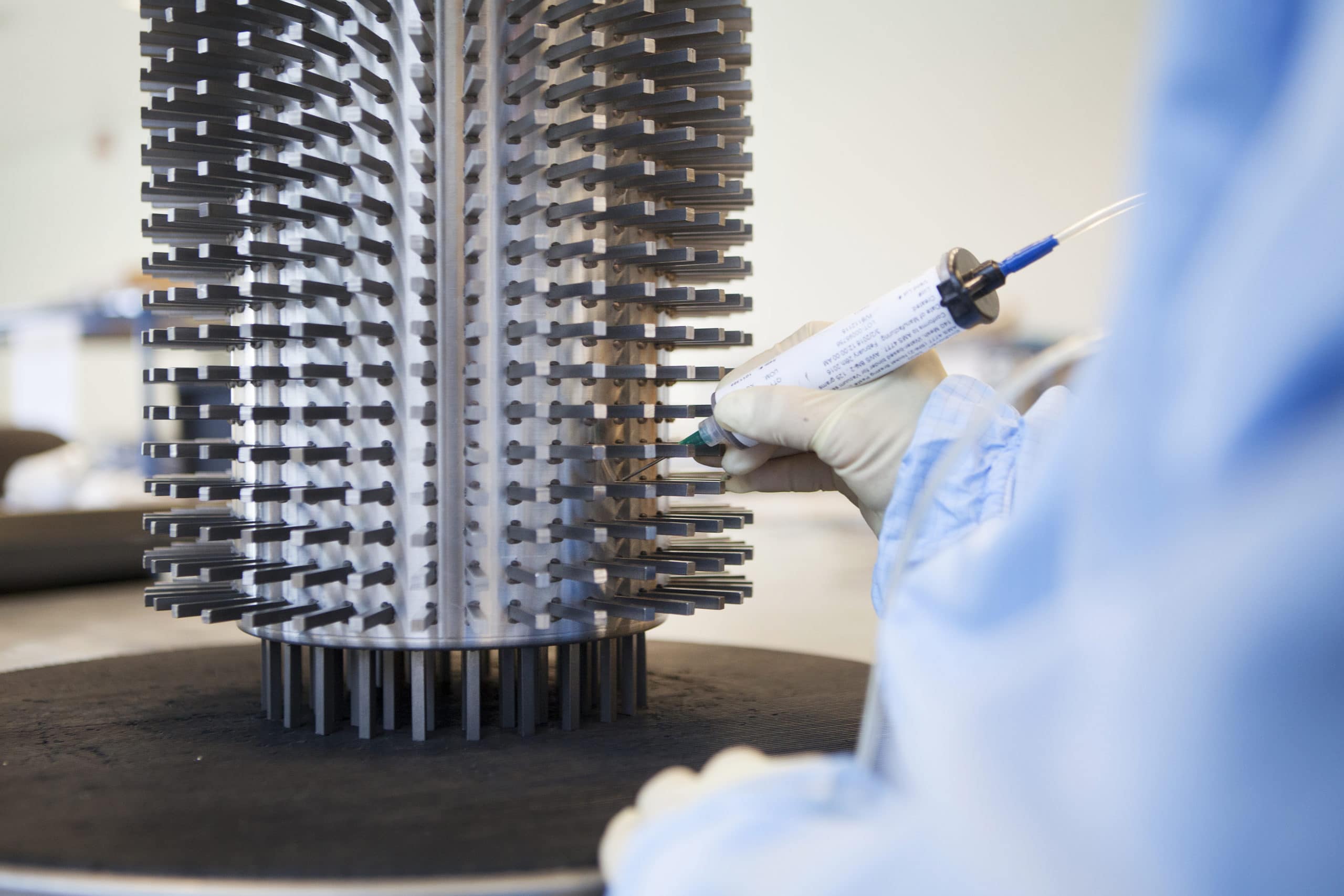

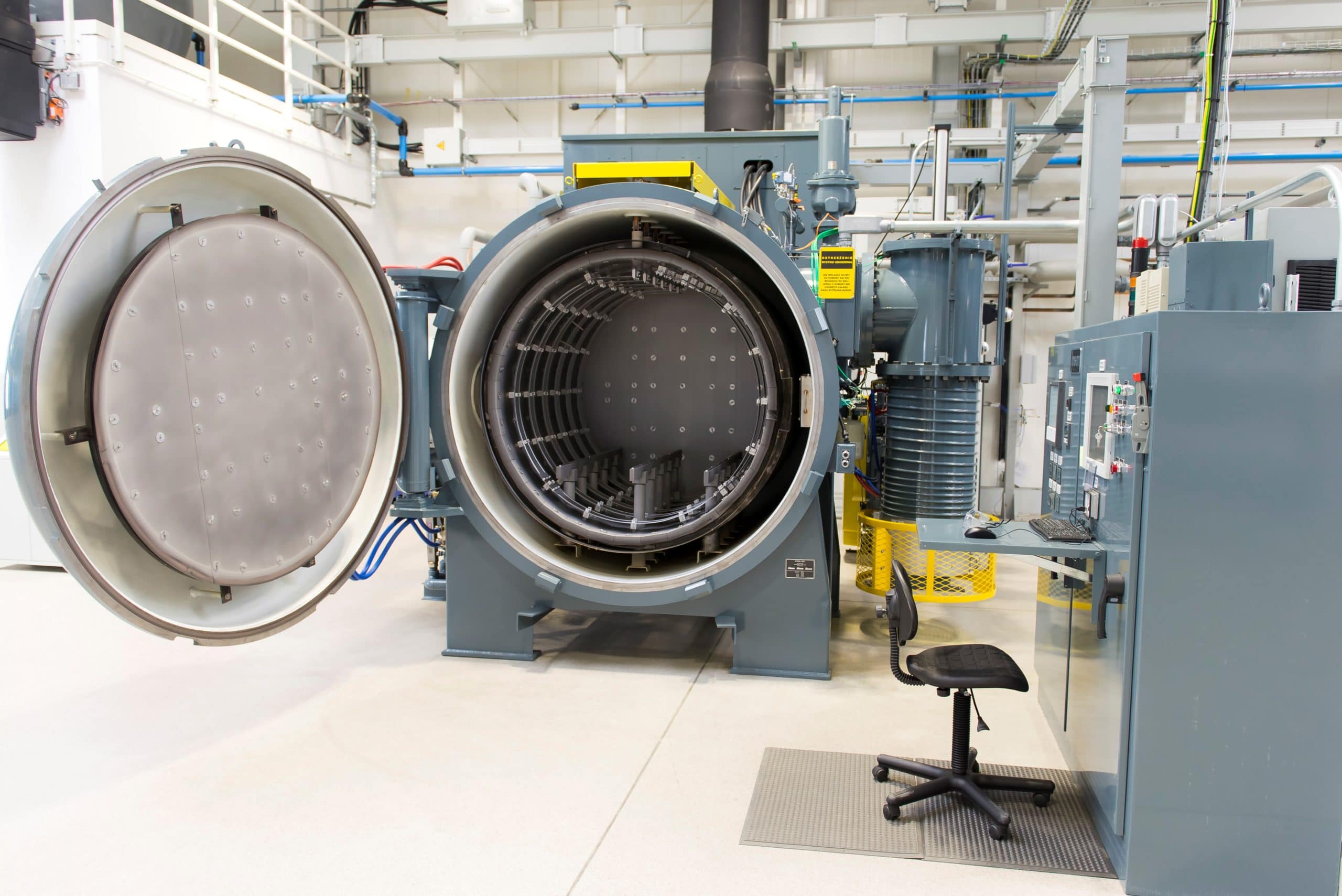

Whether you need through-hardening and tempering or surface hardening, nitriding or surface coating and finishing for your components, we have a wide range of treatment options at your disposal that will both improve the durability and generally optimize usability of your tools. With its modern furnaces offering numerous quenching methods and various other baths and plants, Aalberts surface technologies can fulfil almost any treatment demand in the field of tool manufacturing and thus optimize tools in a variety of different ways.

The quality monitoring of batches and consistent documentation of all relevant process parameters provide our customers with the quality, sustainability and support they require. If you have any questions regarding the heat treatment and surface coating of tools, please do not hesitate to contact us. Our consultants are always happy to help you out with their expertise, in particular with regard to the best possible processing of your tools.

applicable processes

process locations

get in touch

Select your preferred process location or contact us directly.