polymer coating

Aalberts surface technologies Moers

about this location

welcome to Moers

In 2019, the former GF-Flamm-Metallspritz GmbH Moers (founded in 1979) was integrated into the Aalberts Group and renamed Aalberts Surface Technologies GmbH. With our coating solutions, we improve both the protection and functionality of new parts, as well as those of repair stressed and worn components.

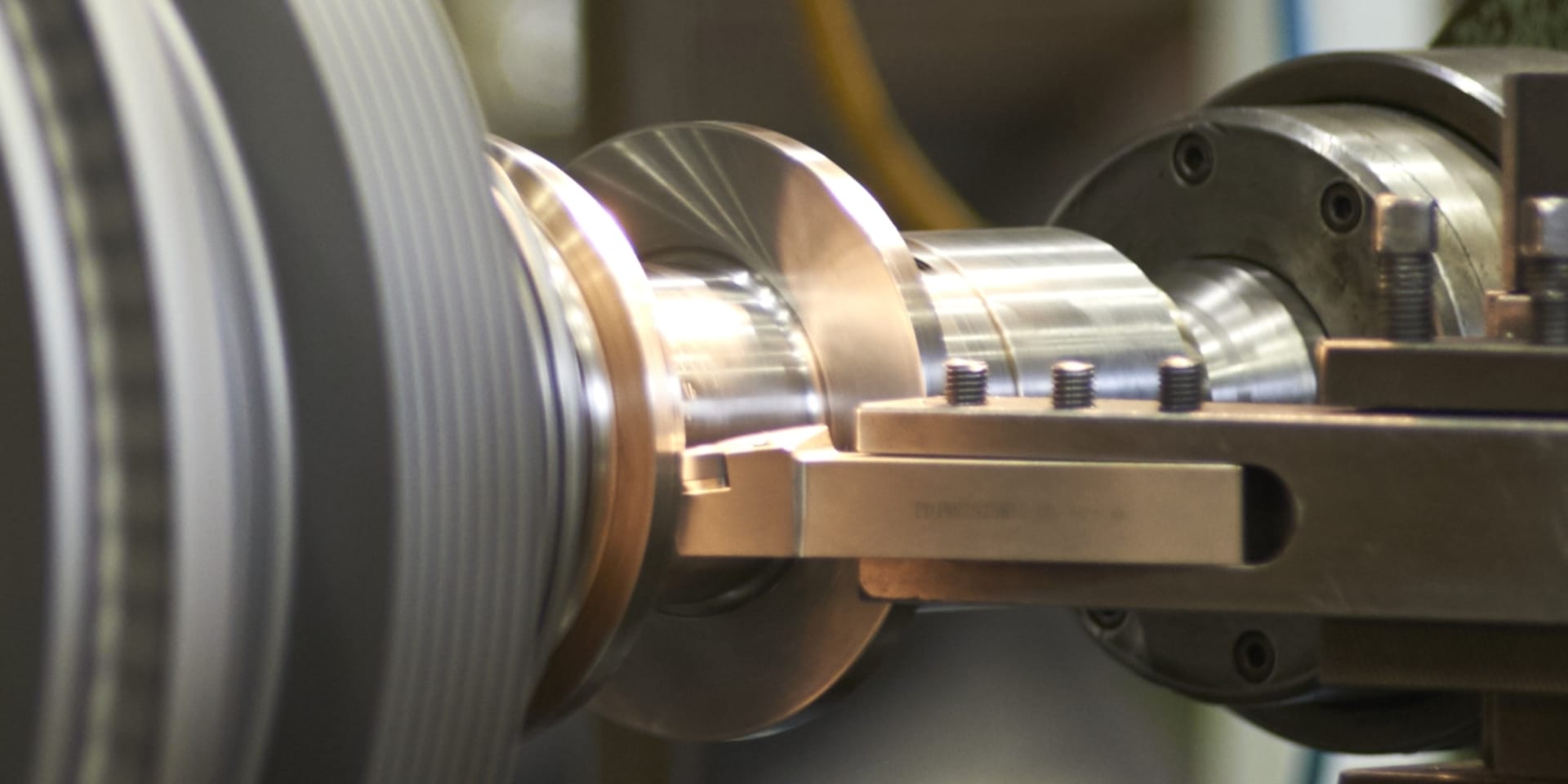

In addition to coatings through the means of various thermal spraying processes, Aalberts surface technologies Moers also provides the necessary mechanical pre-machining and finishing. This includes processes such as turning, honing, lapping and grinding as well as superfinishing. If required, we can also carry out the coating on your premises.

our services for surface technology in Moers

We know the technology of our customers, the function of their components and the requirements in use. For us, cooperation based on partnership is the basis for an optimal solution to your individual problems. Technical know-how, qualified employees and efficient machines and plants guarantee short delivery times with excellent coating quality and precise dimensional accuracy.

process overview

| process | max. size in mm | max. weight in kg |

| Arc spraying | D1500xL10000 D3250xL3000 | 18000 |

| Flame spraying and fusing | D300xL3350 D2000xL1000 | 2000 |

| High velocity flame spraying (HVOF) | D1500xL10000 D3250xL3000 | 18000 |

| Powder flame spraying | D1500xL10000 D3250xL3000 | 18000 |

process services

- Coating by thermal spraying

- Pre-machining and finishing by turning, grinding, honing, superfinishing

- Repair and overhaul of worn components

- Preventive wear and corrosion protection of new parts

- Functional coatings for special surface properties

coating materials

- Molybdenum

- Chrome/chrome-nickel steels

- Hard metals from tungsten and chromium carbide

- Nickel- and cobalt-based hard alloys

- Nickel-chromium alloys

- Bronze

- White metal

special services

- Technical advice on coating selection and design

- Application-oriented layer development

- Quality assurance layer and component testing

- Complete production of coated components

- Powder flame spraying

- Wire flame spraying

- Flame spraying and melting down

- High velocity flame spraying

- Arc spraying

- Turning

- Grinding

- Honing

- Superfinishing

|

Machinery |

Ø (mm) |

length/ height (mm) |

weight (t) |

|

injection bench |

1500 |

10000 |

18 |

|

spray lathe |

3250 |

3000 |

12 |

|

Turning & Support Loops |

1450 |

8000 |

12 |

|

cylindrical grinding |

650 |

3500 |

2 |

The rise in the performance and productivity of machinery and equipment increases the stress on the components and requires additional measures to secure the function. Highly stressed surfaces must be protected so that they can withstand the loads. Wear-resistant coatings ensure functionality, increase the service life and provide those desired properties. Many applications are only made possible by applying a coating via the process of thermal spraying.

Wear is one of the undesirable side effects in the industrial environment when moving parts are in contact. Changes in part geometry or surface properties lead to a lack of the function or even the failure of the system. With thermal sprayed coatings, the geometry and function of worn components can be recovered and further improve the properties of the surface. Due to our experience we make your components reusable for their application.

quality and know-how

applications

Thermal spray applications include wear and corrosion protection, electrical and thermal insulation or conductivity, and the generation of certain friction and sliding properties. Thermal spraying is ideal for stressed and worn components to restore geometry and function. Through the targeted selection of the coating material and the coating process, we can also guarantee longer service lives and optimum functioning of the component.

application examples

- Slide bearing and sealing seats of turbines and compressor rotors

- Bearing and coupling seats of drive shafts

- Piston rods and cylinder running surfaces of compressors

- Bearing bores of pedestal bearings, gear housings or gear wheels

- Erosion and corrosion protection of turbomachinery components

- Fan blades and conveying elements

downloads

Aalberts surface technologies offers security. We want to offer you the greatest possible security. That is why our Aalberts surface technologies sites are certified.

certificates

general terms and conditions

our inhouse processes

We are the right partner for thermal spraying. Our competence in Moers also includes partial coating of components and keeping technically necessary areas of the components free from coating. In individual areas we also offer light assembly steps after coating.

industries we serve

contact & directions

Aalberts Surface Technologies GmbH