where robustness meets durability

thermal spraying

what is thermal spraying?

Thermal spraying is the process of applying a coating material in powdered or wire form to a surface to improve or modify its properties. The surface coating process is typically performed using a thermal energy source such as a flame, plasma or arc to melt or vaporize the spray material. The melted or vaporized material is then sprayed onto the surface to be coated, where it emerges and cools to form a thin, homogeneous coating.

Thermally sprayed coatings are characterized by high surface hardness as well as excellent non-stick properties. Using metals, ceramics and polymers, our experienced Aalberts surface technologies team create the optimum protection for heavily stressed components in a variety of process variants.

thermal spraying at Aalberts surface technologies

We will cooperate with you in order to find the coating process to match your material. All kinds of surfaces can be coated using thermal spray: aluminum, steel, and other types of metals, but also glass, ceramics, plastics, and more. From initial sampling to series introduction, we will determine the relevant process steps together with you. We also support you in choosing the right spraying method such as flame spraying, plasma spraying or arc spraying. Upon request, we will supplement our technical services by a logistics concept with pick-up and delivery services tailored to your needs. We will find the right solution for your needs – request a quote now and use the contact form at the bottom!

PlasmaCoat® thermal spraying for excellent non-stick properties

Our PlasmaCoat® thermal spray coating process comprises different coatings which are applied to components with varying degrees of roughness and different profiles with the aim of creating surfaces with excellent non-stick and traction properties as well as corrosion protection. Prior to thermal spraying applications, we clean the material and roughen up its surface. This results in the spray particles’ mechanical adherence to the surface and guarantees coating adhesion strength. An embedded metal or ceramic layer serves as a substrate for the anti-corrosion coating. Depending on the coating type and application, the coating thicknesses customary to thermal spraying range between one-tenth of a millimeter and several millimeters.

properties of thermal spray coatings

Our PlasmaCoat® spray coating process merges the extreme surface hardness and excellent wear protection of thermally sprayed metal or ceramic coatings with the non-stick and gliding properties of polymers and fluoropolymers. In this way, we prolong the service life of components subject to heavy mechanical loads. When mechanically reworked, PlasmaCoat® coatings can also replace hard-anodized layers. Precise diamond tools are usually required for high quality and clean reworking of the hard surfaces. Thanks to our comprehensive expert knowledge and high-quality tools, the results we achieve are accurate to one-thousandth of a millimeter.

By the targeted thermal spray coating of different materials, we also create other excellent functionalities, such as:

- Non-stick properties

- Improved tribological values

- Corrosion resistance

- Very low porosity

- Low degrees of roughness

- Resistance to temperatures

base materials suitable for thermal spraying

PlasmaCoat® coatings can be applied to almost all metallic materials as well as to CFRP components. Thermal spray coatings are primarily applied to aluminum, steel, stainless steel, cast iron, brass and copper. However, it is also possible to apply this type of coating to ceramics, glass or temperature-sensitive materials, such as (fiber-reinforced) plastics, wood or fabrics. We will find the appropriate procedure for your requirements, be it plasma spraying, electric arc spraying or flame spraying.

fields of application of thermal spraying

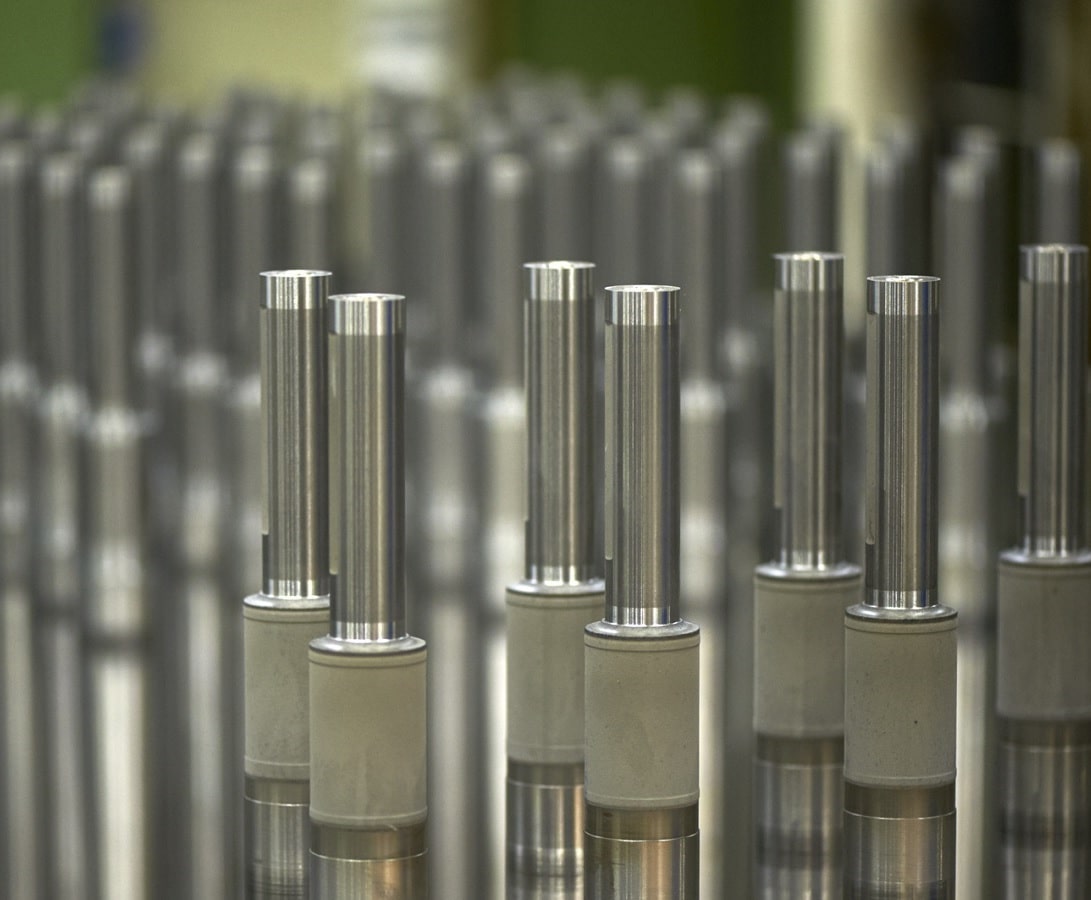

PlasmaCoat® is primarily used as a surface finish in the nonwovens industry. To allow for the safe and trouble-free transport of materials or webs made from plastics, textiles or paper, transport rollers and other relevant components require wear-resistant traction coatings. Depending on the type of application, non-stick and conductive properties might be required as well. Thermal spray coatings by Aalberts surface treatment create precisely these characteristics.

- Gearwheels

- Gear & pinion shafts

- Roller surfaces

- Shaft protection sleeves

- Pins

- Piston rod running surfaces

- Valve spindles

- Cylinders

- Cylinder liners

- Seal seats & sliding fits of rotors

- Axis & shaft seats

- Bearing holes

- Rollers

- Sealing bars

We also offer special repair services: With the help of our processes, worn components can be fully refurbished. When doing so, we restore the required original dimensions along with all the characteristics offered by relatively new protective coatings. As a customer, you will save both costs for new acquisitions and resources.

downloads

industries we serve

frequently asked questions - thermal spraying

Due to the wide range of possible materials and the targeted creation of characteristics, thermal spraying processes are superior to many other coating processes. Apart from metals and metal alloys, it is possible to process hard metals, ceramics and plastics.

Almost all metallic base materials can be finished with thermal spraying (aluminum, steel, cast iron, brass, copper, etc.). However, it is also possible to coat ceramics, glass or temperature-sensitive materials, such as (fiber-reinforced) plastics, wood or fabrics. Since the coating adhesion is usually based on mechanical interlocking, the surfaces to be coated have to be roughened up by sandblasting.

Thermal spraying is an excellent method for repairing worn components, as their original dimensions can be restored while protecting their surfaces against further wear and tear.

Thermal sprayed coatings are particulary characterized by high surface hardness. In addition, some properties such as temperature resistance, corrosion protection or wear protection can be achieved or improved by the coating process. Using metals, ceramics and polymers, our experienced employees create the ideal protection for components subject to heavy loads with different process variants.

process locations

Any questions? Contact us directly or select a process location near you.

other processes

Beuningen

the Netherlands 51.85577565.735604 beuningen@aalberts-st.com +31 24 677 7911 show locationFairburn (Georgia)

United States 33.5542357-84.5850179 info@aalberts-st.us +1 770-969-9191 show locationLüneburg

Germany 53.245976910.4758467 lueneburg@aalberts-st.com +49 4131 882 10 show locationMoers

Germany 51.41045086.6639974 moers@aalberts-st.com +49 2841 88980 0 show locationPulversheim

France 47.8338557.301753 pulversheim@aalberts-st.com +33 389 2832 80 show locationTamworth

United Kingdom 52.5839467-1.6570035 tamworth@aalberts-st.com +44 1827 871 400 show locationUnsere Verfahren

Wir bieten weltweit alle Arten von Wärmebehandlungsprozessen an. Unsere Anlagen sind logistisch eng miteinander verknüpft, so dass Ihnen alle Verfahren zur Verfügung stehen. Erfahren Sie mehr zu unseren Wärmebehandlungsverfahren.

Heiß-Isostatisches Pressen (HIP) dient der Beseitigung von Porosität. Sie benötigen bei Lötverbindungen eine hohe mechanische Haltbarkeit und Unempfindlichkeit bei hohen Temperaturen? Wir bei Aalberts surface technologies bieten die Lösung durch Hartlöten (brazing).

Polymerbeschichtungen können auf viele Grundmaterialien aufgebracht werden und bieten lang anhaltenden Schutz. Sie sind mechanisch besonders gut mit dem Untergrund verankert und bieten verbesserte Gleiteigenschaften und/oder hohe Verschleißfestigkeit.

Mit 40 Jahren Erfahrung in der kontinuierlichen Veredelung von reel to reel können Sie sich auf Aalberts surface technologies verlassen, um innovative Lösungen zu finden. Unser Service umfasst Trommelgalvanik, kontinuierliche selektive Galvanik und Gestellgalvanik.

Fast alle metallischen Grundwerkstoffe können mit unseren selbstentwickelten und patentierten Verfahren durch Oberflächenbeschichtungen in ihren Eigenschaften optimiert werden, egal ob sie besonders hart, glatt, verschleißfest oder korrosionsbeständig sein sollen.

Discover our services

We offer all types of heat treatment processes. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. For a complete list and description of heat treatment technologies please select the button.

Hot isostatic pressing (HIP) is used to eliminate porosity. Do you need high mechanical durability and insensitivity to high temperatures for solder joints? We at Aalberts surface technologies offer the solution through brazing.

Polymer coatings can be applied to a wide variety of base materials and offer long-lasting protection. They are particularly well anchored mechanically to the substrate. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance.

With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. Our service includes barrel plating, continuous selective plating and rack plating.

Almost all metallic base materials can have their properties optimised by surface coatings using our proprietary and patented processes, regardless of whether they should be particularly hard, smooth, wear-resistant or corrosion-resistant.

The Aalberts websites use cookies (read more) to analyse website usage and improve usability. We also use third party tracking-cookies to measure user preferences, enable content sharing on social media and interest-based advertising. If you hit 'accept' you allow to us to place the different types of cookies.

privacy overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |