developing for the plastics industry

creating solutions to surface challenges

Today, customers in the plastic industry not only demand excellent non-stick properties, good demoldability and high wear resistance, they want sustainable solutions, such as conventional separating agents. At the same time, accelerated production speeds and more complex designs of rubber and plastic parts are placing ever-greater demands on the surface systems used in production processes. The plastics industry needs sophisticated heat treatment and surface coatings. And we have the answer.

benefits for the plastics industry

efficient and reliable solutions

Our efficient and reliable solutions improve our customers’ cycle times, significantly reduce their cleaning time, and boosts productivity.

Our plastic coatings become firmly anchored in materials such as steel, stainless steel, aluminum, copper, ceramics and support elements, even those made from plastics.

surface technologies: available globally

We develop complex and unique industrial services, helping thousands of customers across a wide range of industries. And we do it globally, from our operations across three continents. We are your surface technologies partner.

- Traction and non-stick coating of cylinders and rollers the foil processing

- Non-stick coating for flat nozzles in film manufacturing

- Better mold removal in injection molding via nonstick coating

- Carbonitriding (in vacuum or atmospheric) for wear resistance of matrices

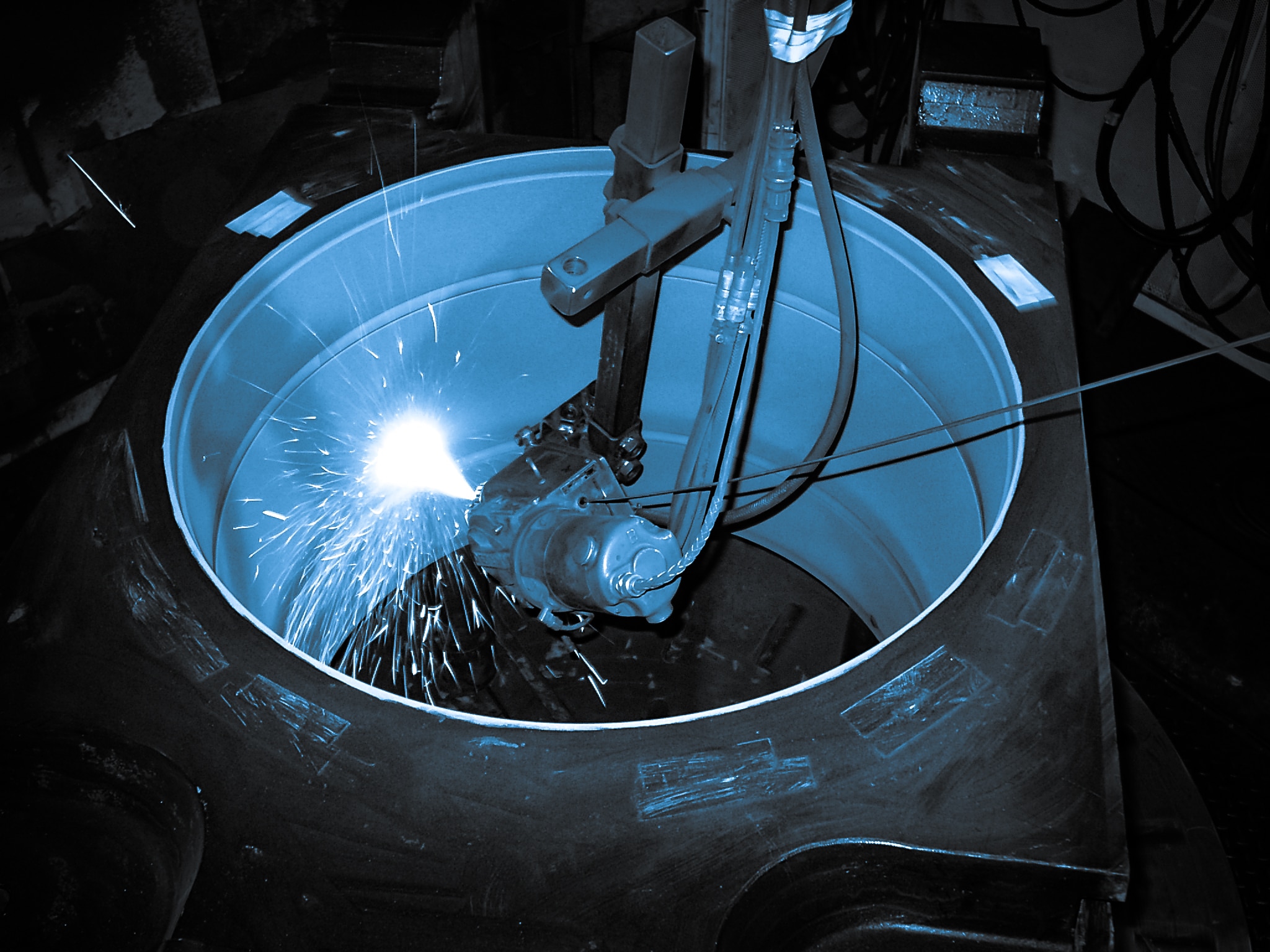

Our comprehensive range of premium products fulfills all the requirements of the plastics industry. Where required, an intermediate metal or ceramic layer may be applied by thermal spraying or a transformation by heat treatment of the base material structure may be done. Such treatments create a high degree of surface hardness. The subsequent possible plastic coating is applied using infusion technology based on powder coating. Our polymer and fluoropolymer finishes also offer excellent corrosion protection and a high resistance to chemicals.

Accordingly, the range of applications is very versatile:

- Welding mirrors

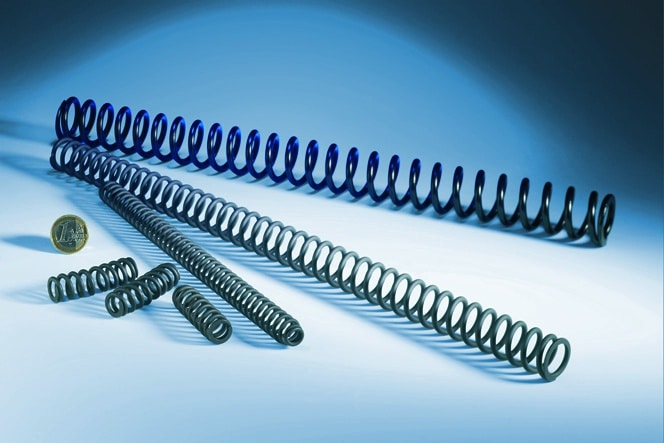

- Rollers (smooth rollers and structured rollers)

- Sealing bars

- Molds and injection molds

- Glue nozzles and spray nozzles

To provide you with a better impression of our tailor-made systems, we have compiled a small selection of the optimization solutions we have developed for the plastics industry.

During the production of special films, large sheets of film have to be double-coated with adhesive whose material properties differ depending on the application. After that, the film is dried using several flat fan nozzles arranged in a row. These nozzles blow air onto the sheets of the film. At the end of the plant, the cooled film is cut and finally wound onto rolls.

The nozzles need to be cleaned after each production job. Depending on the adhesive used, the intensity of the adhesions differs so that it might take up to 30 minutes to clean a single nozzle. But the duration of the cleaning process is not the only disadvantage. In the long run, this mechanical cleaning process will damage the surface and thus the functionality of the nozzle.

When using TempCoat® (formerly known as ChemCoat®) for surface optimizations in the plastics industry, the nozzle surfaces’ non-stick properties are considerably improved. Less adhesive remains stuck to the nozzles, and the adhesive residues can be easily wiped off with a cloth. Additionally, the nozzles become resistant to wear and tear. Since the coating does not affect the electrical conductivity, the film does not become electrically charged. Thanks to the coating, cleaning requirements for the flat nozzles can be reduced by 95%, which results in significantly increased productivity.

The manufacture of isolators for energy facilities involves the production of injection-molded parts. First, a liquid elastomer is injected into the steel tool (consisting of mold core, mold shell and base plate) under pressure and heat. After cooling, the finished component is removed from the mold. During the demolding process, adhesions frequently occur between the bridge of the injection channel and the finished product. Any crevices and fractures must be reworked using separating agents.

In order to improve the demolding process, especially in the area of the injection channel, our specialists use TempCoat® (formerly known as ChemCoat®) surface coating for the plastics industry. This durable non-stick coating ensures that the finished parts can always be perfectly removed without causing any crevices and fractures.

The advantages of this surface finish speak for themselves:

- Easier and quicker demolding

- No rejects

- Cost savings with regard to release agents

- No undesired damages to the mold, increasing the service life

Film strips for cigarette pack wrappings are processed using rollers between which the material is transported back and forth. The film must be glued, laminated, cut and packed. Due to the rollers’ smooth surface, the functionality might be limited: the film slips off or tears under excessive tension. The production needs to be interrupted and a lot of material gets lost due to slippage when the plant is restarted.

Production processes in the plastics industry can be considerably improved when rollers are coated with TempCoat® (formerly known as ChemCoat®) and PlasmaCoat®. The improved traction properties keep the film from slipping off or tearing. Additionally, the rollers become resistant to wear and tear, which keeps the film from getting damaged during cutting or punching processes. The rollers’ required electrical conductivity remains unaffected. Not only does the use of surface technologies avoid losses caused by production downtimes, it also cuts production costs.

process locations

get in touch

Select your preferred process location or contact us directly.