anti-corrosion coating

zinc flake coating

what is zinc flake coating?

Zinc flake coating is a coating of zinc and aluminum flakes that is applied to protect against corrosion.

The zinc flake coating protects the underlying metal from environmental influences. Zinc flake coating is applied with state-of-the-art coating techniques, such as dip-spin, rack dip-spin or fully automated spray processes.

Zinc flake coating is used, above all, to reliably protect high-tensile steels, aluminum alloys and die-cast zinc against corrosion. When opting for this non-electrolytic coating solution, the risk of hydrogen embrittlement in the base material is minimized. Originally designed as a chromium VI-free alternative to electroplating, zinc flake anti-corrosion coating has become well established due to its wide range of uses in the automotive sector and other applications. Zinc flake coatings are applied using state-of-the-art dip-spin, dip coating or fully automated wet coating processes. As license holder of the leading suppliers, Aalberts surface technologies can offer these processes at its global facilities.

Depending on the area of application, Aalberts surface technologies also offers different pre-treatments, such as degreasing, sandblasting and phosphating. In order to find the base and top coat solutions that best match your components, we will provide you with individual advice and cooperate with you to determine the relevant work steps from initial sampling to series production. Upon request, we will complete our technical services by a logistics concept with pick-up and delivery services tailored to your needs. We apply zinc flake coatings using dip-spin processes for bulk goods, rack dip-spin techniques and (fully automated) spray methods.

properties of zinc flake coating

Apart from high corrosion resistance, the outstanding properties of zinc flake coating also include constant coefficients of friction, dimensional accuracy and individual coloring. Not only is this surface coating free from chromium VI, but its zinc and aluminum flakes offer cathodic corrosion protection. Hydrogen embrittlement, as known from electroplated zinc layers, does not occur. The application of specifically developed combination layers, moreover offers the possibility to achieve good non-stick properties and to optimize the zinc flake coating’s gliding properties.

A few characteristics at a glance:

- Long-term corrosion protection under cyclic loads

- > 1,000h free from red rust in the salt spray test (DIN EN ISO 9227)

- Delayed formation of red & white rust and contact corrosion

- Resistance to chemicals (acids, alkalis, cleaners, oils, gasoline)

- Thin layer thicknesses (6 – 25 µm) are possible

- Topcoat for Duplex coatings and non-ferrous metal

- Temperature resistance (180 – 300 °C, depending on the product)

- Process temperatures from air drying to thermal cross-linking

Base materials

Aluminum alloys, steel, stainless steel and die-cast zinc are among the base materials suitable for zinc flake coating.

fields of use of zinc flake coating

It is used primarily in the automotive industry and wherever excellent corrosion protection combined with other functional and decorative properties is paramount. Aalberts surface technologies fulfills the entire set of specifications of the international automobile manufacturers.

The most important applications at a glance:

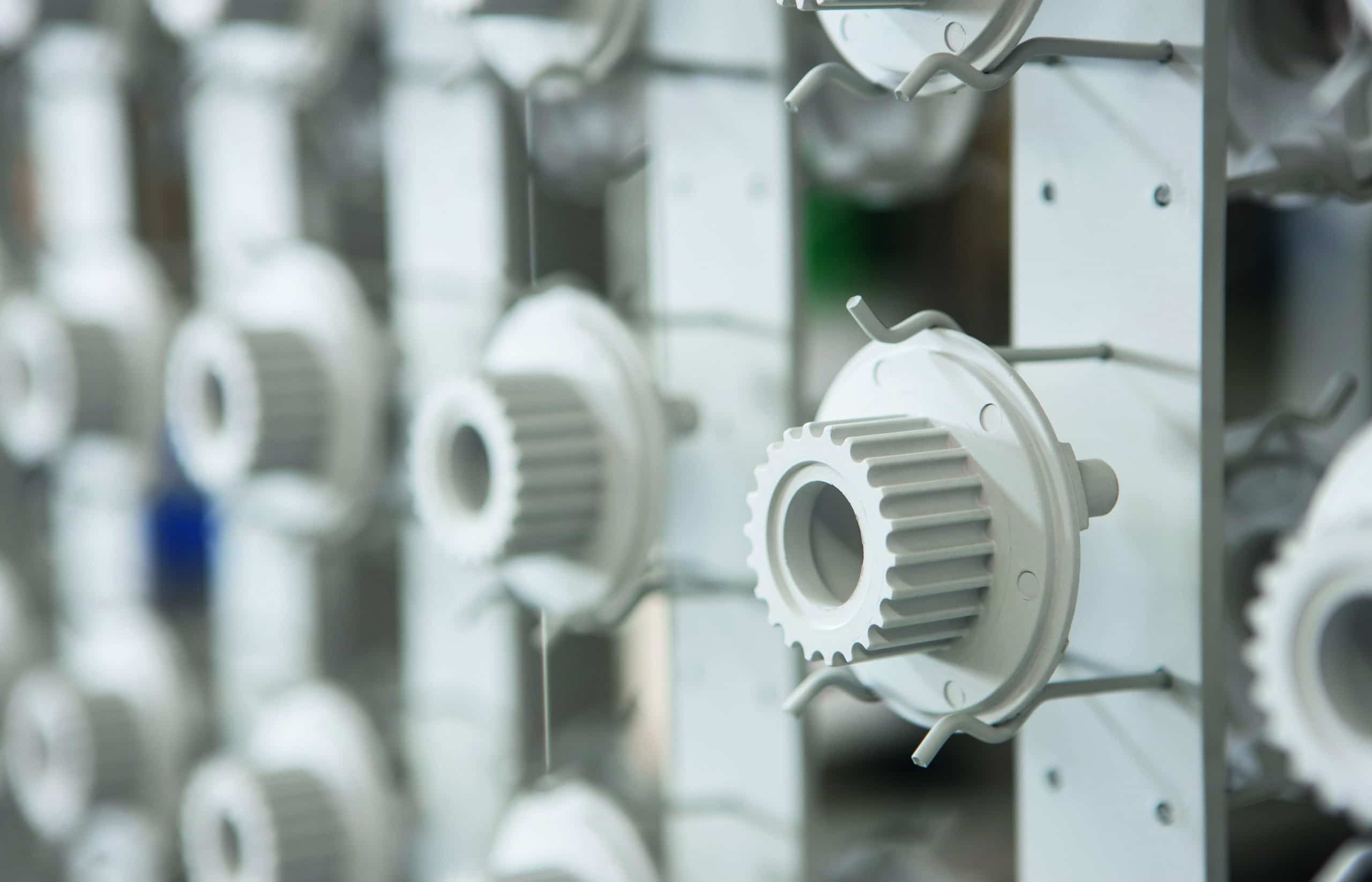

- Fastening elements

- Brake components

- Chassis components

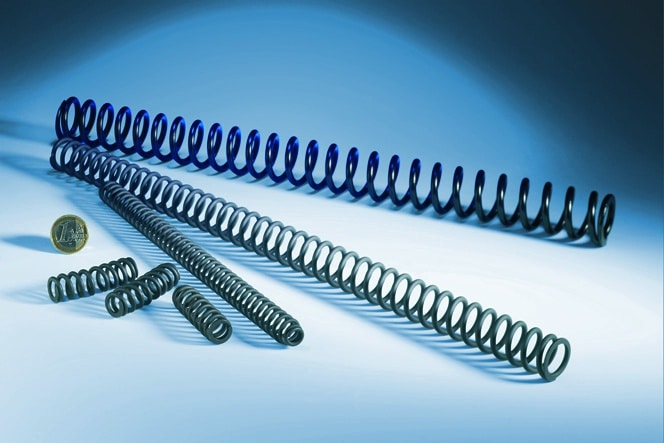

- Springs

- Threaded parts

- Punched parts

downloads

industries we serve

frequently asked questions - zinc flake coating

Thin-film zinc flake coatings offer long-lasting corrosion protection, especially under cyclic loads. Applied in non-electrolytic processes, they prevent hydrogen embrittlement in the base material.

Further advantages include:

- No hydrogen embrittlement

- No warping

- Secure coating of cavities and undercuts

- Best possible corrosion protection for high-tensile components

- Very good protection against contact corrosion

- Available worldwide and established in all sectors

Our zinc flake systems can be combined with colored topcoats.

Topcoats created with zinc flake coating processes can be combined with electroplating systems and other base coats. Compared to other electroplated coatings, for example, they significantly increase the material’s protection against corrosion and optimize its functional properties.

Topcoats are also used with the aim of protecting non-ferrous metals or optimizing their features.

Zinc flake systems have become an integral part of the automotive industry. The majority of all connecting elements are coated with zinc flake systems, not least because the requirements have significantly increased in recent years. With the aim of protecting materials or optimizing their functions, Zinc flake systems are also universally used for structural parts and chassis components as well as in the composite/mixed construction area.

While zinc plating uses electrical current to apply the zinc coat, zinc flake coating is a non-electric process where zinc and aluminum flakes are applied with the use of different coating techniques such as dip-spin, rack dip-spin or spraying. Both processes aim to increase corrosion resistance.

process locations

Any questions? Contact us directly or select a process location near you.

Cleveland (Tennessee)

United States 35.1227709-84.9104398 info@aalberts-st.us +1 423 559 9900 show locationDeurne

the Netherlands 51.45566135.7704517 deurne@aalberts-st.com +31 493 352 820 show locationLandsberg am Lech

Germany 48.068575810.8542243 landsberg@aalberts-st.com +49 8191 91186 10 show locationLüneburg

Germany 53.245976910.4758467 lueneburg@aalberts-st.com +49 4131 882 10 show locationNidda

Germany 50.42982898.9779735 nidda@aalberts-st.com +49 6043 9613 0 show locationPulversheim

France 47.8338557.301753 pulversheim@aalberts-st.com +33 389 2832 80 show locationShanghai

China 31.175354121.135765 shanghai@aalberts-st.cn +86 (21) 6921 1758 show locationTatabánya

Hungary 47.582185518.3456132 tatabanya@aalberts-st.com +36 34 5146 70 show locationUnsere Verfahren

Wir bieten weltweit alle Arten von Wärmebehandlungsprozessen an. Unsere Anlagen sind logistisch eng miteinander verknüpft, so dass Ihnen alle Verfahren zur Verfügung stehen. Erfahren Sie mehr zu unseren Wärmebehandlungsverfahren.

Heiß-Isostatisches Pressen (HIP) dient der Beseitigung von Porosität. Sie benötigen bei Lötverbindungen eine hohe mechanische Haltbarkeit und Unempfindlichkeit bei hohen Temperaturen? Wir bei Aalberts surface technologies bieten die Lösung durch Hartlöten (brazing).

Polymerbeschichtungen können auf viele Grundmaterialien aufgebracht werden und bieten lang anhaltenden Schutz. Sie sind mechanisch besonders gut mit dem Untergrund verankert und bieten verbesserte Gleiteigenschaften und/oder hohe Verschleißfestigkeit.

Mit 40 Jahren Erfahrung in der kontinuierlichen Veredelung von reel to reel können Sie sich auf Aalberts surface technologies verlassen, um innovative Lösungen zu finden. Unser Service umfasst Trommelgalvanik, kontinuierliche selektive Galvanik und Gestellgalvanik.

Fast alle metallischen Grundwerkstoffe können mit unseren selbstentwickelten und patentierten Verfahren durch Oberflächenbeschichtungen in ihren Eigenschaften optimiert werden, egal ob sie besonders hart, glatt, verschleißfest oder korrosionsbeständig sein sollen.

Discover our services

We offer all types of heat treatment processes. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. For a complete list and description of heat treatment technologies please select the button.

Hot isostatic pressing (HIP) is used to eliminate porosity. Do you need high mechanical durability and insensitivity to high temperatures for solder joints? We at Aalberts surface technologies offer the solution through brazing.

Polymer coatings can be applied to a wide variety of base materials and offer long-lasting protection. They are particularly well anchored mechanically to the substrate. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance.

With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. Our service includes barrel plating, continuous selective plating and rack plating.

Almost all metallic base materials can have their properties optimised by surface coatings using our proprietary and patented processes, regardless of whether they should be particularly hard, smooth, wear-resistant or corrosion-resistant.

The Aalberts websites use cookies (read more) to analyse website usage and improve usability. We also use third party tracking-cookies to measure user preferences, enable content sharing on social media and interest-based advertising. If you hit 'accept' you allow to us to place the different types of cookies.

privacy overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |