nickel phosphorus alloy coatings

electroless nickel plating

what is electroless nickel plating?

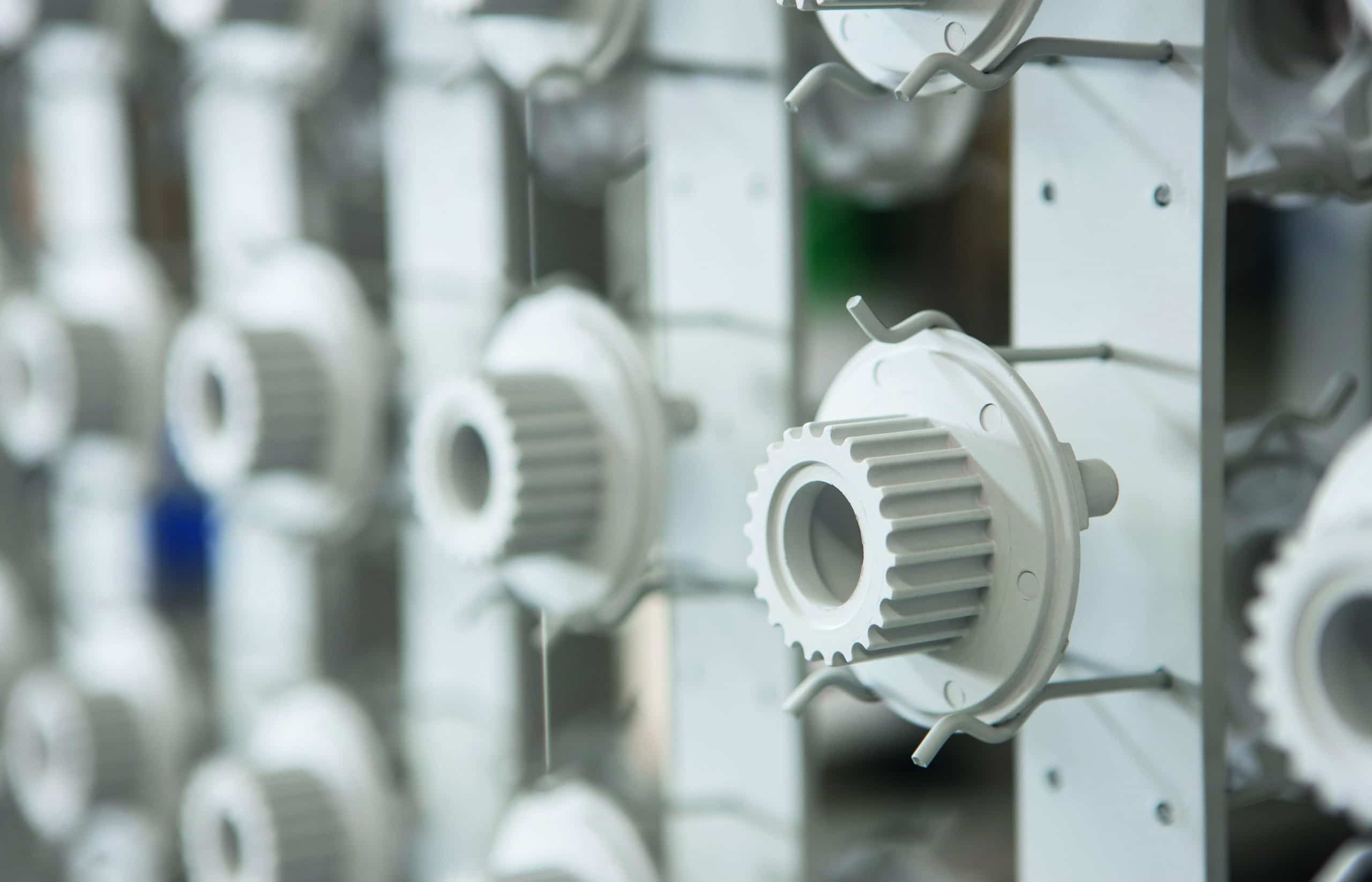

Electroless nickel plating (chemical nickel plating) is a procedure that has been used since the 1950s for finishing surfaces with a nickel-phosphorus coating. Apart from aluminum and steel, all other base materials may be optimized with electroless nickel plating. High precision, uniform plating thicknesses – especially when it comes to components with complex shapes – and safety during series production are among the many advantages offered by this process. The dispensability of an external power source makes electroless nickel plating even more interesting.

Aalberts surface treatment is your partner when it comes to electroless nickel plating. Equipped with state-of-the-art technology, our factories will finish your components in a highly functional and economic way.

metal finishing with DURNI-COAT®

Our most important method for the functional finishing of metals with electroless nickel plating is called DURNI-COAT®, referred to in short as DNC. Customized to the type of material, processing and use, it protects metal components against wear and corrosion. When it comes to this nickel coating process, Aalberts surface treatment can look back on more than 50 years of practical experience. Every year, we durnicoat more than 350 million components.

DURNI-COAT® nickel coatings are ideal for applications with special requirements. The scope of performance covers everything from chemical resistance to dimensional accuracy and ideal gliding behavior to increased hardness. Below we have summarized the most important coating properties:

- Excellent corrosion resistance

- Erosion and cavitation resistance

- High resistance to wear

- Elongation at break of up to 2%

- Uniform coating deposition

- Good dimensional accuracy

- Excellent hardness

- Magnetic properties

- Joinability / solderability

- Conductive surface

- Ideal frictional behavior

- Good chemical resistance

our DURNI-COAT® chemical nickel plating process

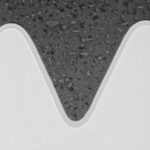

Our versatile DURNI-COAT® electroless nickel plating processes are characterized by uniform and accurate coating depositions, even on geometrically complex surfaces. Edges, recesses, accessible cavities and drillings will thus be evenly coated as well. This is an advantage, especially in comparison with electroplated coatings. The uniform DURNI-COAT® layer allows for narrow plating thickness tolerances: ±10 percent of the required plating thickness are common, whereas the minimum tolerance is ±3μm.

fields of application for DURNI-COAT® electroless nickel plating

DURNI-COAT® chemical nickel plating is used in many sectors, such as the automotive industry, the chemical industry, the electrical engineering industry, the mechanical engineering industry, the textile industry and the area of aircraft construction.

Durnicoated surfaces can also be suitable for use in the food industry, but this is subject to special requirements, including VO (EC) 1935/2004 and VO (EC) 2023/2006. More information on requirements and conditions can be found here.

The range of base materials which can be finished with DURNI-COAT® comprises the metals most frequently used in technical applications:

- All low-alloy ferritic steels

- Cast-iron materials

- Stainless steels

- Non-ferrous metals, such as copper, brass and bronze

- Aluminium alloys

- Sintered metals

- Further materials following previous sample coatings

standard DURNI-COAT® plating thicknesses

Layer thicknesses of 2 to 5 μm are sufficient when DURNI-COAT® coatings are used as soldering aids. When selecting the DURNI-COAT® variants and layer thicknesses, it is moreover necessary to consider the corrosive environment, the type and quality of the base material and its surface, the tribological system and the required service life.

According to DIN EN ISO 4527, the following plating thickness distribution is common for parts subject to wear and corrosion:

- Minor stress

- 5 to 10 μm (when subject to wear)

- 2 to 10 μm (when subject to corrosion)

- Moderate stress

- 10 to 25 μm

- High stress

- 25 to 50 μm

- Extremely high stress

- 50 μm

electroless nickel plating with dispersed PTFE

PTFE-DURNI-DISP surface finish consists of an electroless (chemically) deposited nickel-phosphorus alloy layer applied according to the DURNI-COAT® process in which PTFE dry lubricant is uniformly and

homogeneously dispersed. The dispersion layer combines the properties of the DURNI-COAT® layer with those of the PTFE. The corrosion resistance and hardness of pure DURNI-COAT® layers are barely affected by the dispersed dry lubricant, and the tribological characteristics are actually considerably improved.

downloads

metal finishing with NEDOX®

The NEDOX® electroless nickel plating procedure also involves the application of a nickel-phosphorus alloy onto metal surfaces. This chemical coating contains countless pores created by a series of patented production steps. The controlled diffusion of polymers solidifies the surface. In the final phase of the NEDOX® process, the polymers are fully integrated with the surface. The nickel coating is deposited in a precise and uniform way.

The NEDOX® process creates a hard, smooth and self-lubricating surface with high protection against wear and corrosion. NEDOX® features high chemical stability and comes with lasting non-stick and antistatic properties. There are many variables which can be controlled during the different stages of our NEDOX® process in order to improve different surface properties.

fields of application for NEDOX® electroless nickel plating

A versatile product, NEDOX® is often used as industrial coating in the automotive industry, the energy technology sector (oil and gas), the semiconductor industry, the aerospace industry, the pharmaceuticals industry and the area of pneumatics.

NEDOX® coating is suitable for a great variety of materials, such as

- low-alloy ferritic steels

- cast-iron materials

- stainless steels

- non-ferrous metals such as copper, brass or bronze

- aluminium alloys

- sintered metals

- further materials provided that their suitability has been confirmed (sample coating).

important properties of NEDOX® coatings

As a leading electroless nickel plating company, Aalberts surface treatment implements different NEDOX® coating variants with individual characteristics. Customized to the requirements of each individual application, the following (combined) properties are paramount:

- Non-slip properties

- Resistance to UV radiation

- Chemical stability

- Noise reduction

- Gliding behavior

- Corrosion protection

- Coatings that prevent the adhesion of adhesive tape and glue

- Temperature resistance

- Wear protection

Friction-enhancing coatings DNC® SIC 9, SIC + and SIC 35

For applications involving frictional torque and force transmission, we offer a reliable solution through targeted functionalization of the relevant surface areas. The nickel coatings with embedded hard material particles applied without external current (chemically) enable a significant increase in the resulting coefficient of friction between two contact partners. In frictional connections, higher forces or moments can thus be transmitted without having to increase the surface ratios or the dimensions of the components.

The function of the frictional connection is ensured by the embedded silicon carbide particles (SiC). Depending on the application conditions and the base and counter bodies, friction coefficients of over 0.5 can be achieved in this way. The incorporation of the SiC particles also increase the wear resistance of the coating.

One advantage of electroless metal deposition compared to galvanic processes is the uniform and almost geometry-independent layer thickness distribution, which also remains the case with this process variant. The silicon carbide particles used have a high hardness (up to 2,500 HV) and temperature resistance (up to almost 2,000 °C). In addition, they are chemically very resistant even at high temperatures and are ecologically and regulatory harmless.

The coatings have already proven themselves many times over in various applications and industries and are applied by our specialists at the Eindhoven plant in accordance with the most precise pre-defined requirements for our customers.

industries we serve

frequently asked questions

All metallic base materials, i.e. steel, high-alloy steel, stainless steel, aluminum, non-ferrous metals (copper, brass, bronze), and die-cast zinc. The suitability of further materials needs to be checked by means of sample coatings.

Not for the (main) coating process (electroless nickel plating). However, it might be required for the pre-treatment of some materials (stainless steel, die-cast zinc, non-ferrous metals).

- Extremely uniform plating thickness distribution, even on component surfaces with complex geometries

- Ideal combination of wear and corrosion protection

- Electrical conductivity and stainless steel look

Depending on the application, it is possible to achieve plating thicknesses between 5µm and 50µm. In exceptional cases, a thickness of 100µm can be achieved (when using special rack systems).

Our versatile DURNI-COAT® electroless nickel plating processes are characterized by uniform and accurate coating depositions, even on geometrically complex surfaces.

process locations

Any questions? Contact us directly or select a process location near you.

other processes

Chicago (Illinois)

United States 41.9897386-87.7325852 sales@ppc1904.com +1 773 583 3333 show locationCormenon

France 47.97014060.8907598 ast.cormenon@aalberts-st.com +33 (0) 2 54 73 45 40 show locationEindhoven

the Netherlands 51.43406225.4346575 eindhoven@aalberts-st.com +31 402 5076 07 show locationGöppingen

Germany 48.66539429.6795345 eschenbach@aalberts-st.com +49 7161 15688 0 show locationKerpen

Germany 50.88076.6800999 kerpen@aalberts-st.com +49 2237 502 0 show locationKirchheim-Heimstetten

Germany 48.151143811.7440283 muenchen@aalberts-st.com +49 89 990241-0 show locationWeiterstadt

Germany 49.897638.61422 weiterstadt@aalberts-st.com +49 6151 9806 0 show locationBerlin

Germany 52.528455313.5331206 berlin@aalberts-st.com +49 30 549904 0 show locationUnsere Verfahren

Wir bieten weltweit alle Arten von Wärmebehandlungsprozessen an. Unsere Anlagen sind logistisch eng miteinander verknüpft, so dass Ihnen alle Verfahren zur Verfügung stehen. Erfahren Sie mehr zu unseren Wärmebehandlungsverfahren.

Heiß-Isostatisches Pressen (HIP) dient der Beseitigung von Porosität. Sie benötigen bei Lötverbindungen eine hohe mechanische Haltbarkeit und Unempfindlichkeit bei hohen Temperaturen? Wir bei Aalberts surface technologies bieten die Lösung durch Hartlöten (brazing).

Polymerbeschichtungen können auf viele Grundmaterialien aufgebracht werden und bieten lang anhaltenden Schutz. Sie sind mechanisch besonders gut mit dem Untergrund verankert und bieten verbesserte Gleiteigenschaften und/oder hohe Verschleißfestigkeit.

Mit 40 Jahren Erfahrung in der kontinuierlichen Veredelung von reel to reel können Sie sich auf Aalberts surface technologies verlassen, um innovative Lösungen zu finden. Unser Service umfasst Trommelgalvanik, kontinuierliche selektive Galvanik und Gestellgalvanik.

Fast alle metallischen Grundwerkstoffe können mit unseren selbstentwickelten und patentierten Verfahren durch Oberflächenbeschichtungen in ihren Eigenschaften optimiert werden, egal ob sie besonders hart, glatt, verschleißfest oder korrosionsbeständig sein sollen.

Discover our services

We offer all types of heat treatment processes. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. For a complete list and description of heat treatment technologies please select the button.

Hot isostatic pressing (HIP) is used to eliminate porosity. Do you need high mechanical durability and insensitivity to high temperatures for solder joints? We at Aalberts surface technologies offer the solution through brazing.

Polymer coatings can be applied to a wide variety of base materials and offer long-lasting protection. They are particularly well anchored mechanically to the substrate. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance.

With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. Our service includes barrel plating, continuous selective plating and rack plating.

Almost all metallic base materials can have their properties optimised by surface coatings using our proprietary and patented processes, regardless of whether they should be particularly hard, smooth, wear-resistant or corrosion-resistant.

The Aalberts websites use cookies (read more) to analyse website usage and improve usability. We also use third party tracking-cookies to measure user preferences, enable content sharing on social media and interest-based advertising. If you hit 'accept' you allow to us to place the different types of cookies.

privacy overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |