heat treatment

Aalberts surface technologies Dzierżoniów

about this location

The Dzierżoniów plant was established in 2014 with a completely new building, as one of the investments of the Aalberts group in this region. Our target markets are automotive as well as the mechanical engineering industry. We are located in the south-west of Poland, at Industrial Park and are very proud that we’ve created a successful, well-known and profitable business.

We are committed to deliver the highest quality of services not only in the field of heat treatment of your components but also to the way we treat our customers. We always act in close cooperation with our customers and we are able to adapt our processes to the specific requirements.

With our procedures dialed into the automotive industry, combined with in-depth heat treatment expertise, increased volumes, improved efficiency and disciplined capital allocation in new equipment, we are developing this long-term production program with a focus on Central and Eastern Europe.

As an exclusive and strategic supplier, we demonstrate our competence for critical mass production.

“Being “best in class” is not about our core technologies, but about our flexibility with which we service our customers and the way we are able to integrate our processes in their supply chain.” Bartlomiej Olejnik, managing director

quality

As a commercial heat treatment company, we are strongly focused on quality and process technology. Thus, we work closely with our customers to ensure that our production is always tailored to their specific needs. Existing processes and applications are optimized and new possibilities are continuously developed.

Using the experience offered by our experts and the possibilities afforded us by our own in-house material analysis laboratory, we develop the optimal solution for any customer.

Our plant technologies enable us to implement such solutions, whether they involve individual pieces or large-volume series.

We avail of many years of experience in dealing with the high demands of the automotive, power aerospace and mechanical industries.

quality system

We are a company open to new IT solutions, to streamlining all processes within the organization. Planning and control of production take place using the latest ERP system technology, which allows us to ensure Just in Time deliveries to our customers.

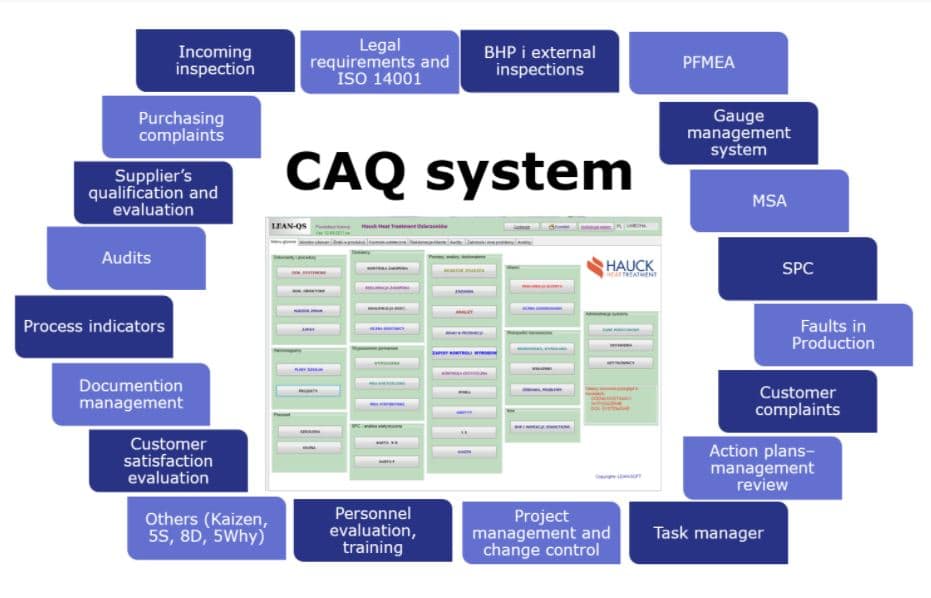

The continuously developed a fully Integrated Management System for Quality (CAQ) in compliance with:

- IATF 16949 (quality)

- ISO 14001 (environment)

- ISO 50001 (energy)

We are fully engaged in delivering safe products and services with a minimum impact on the environment and maintaining high energy efficiency which are both fully compliant with the requirements of our customers.

Our management strategy is based on three fundamentals:

- customer orientation, understanding their needs and ongoing satisfaction assessment

- process and resource management

- continuous analysis of production results, performance indicators and continuous improvement.

We use numerous tools within the Lean Manufacturing philosophy, such as the 5S standard, the Kaizen system, TPM, work standardization and the Six Sigma methodology both at the design stage (DFSS) as well as at the process optimization stage (DMAIC).

heat treatment services

Hardening

The process of thorough hardening consists of combination of hardening and high tempering.

Depending on the cooling medium used, we have the following technologies:

– under protective atmosphere with oil quenching

– in a vacuum atmosphere with gas quenching (max 25 bar abs)

High tempering processes are carried out in a protective or nitrogen atmosphere.

We can distinguish typical, gradual, isothermal, surface finish hardening. Depending on the type of hardening, the steel microstructure is martensite or bainite.

Annealing

The annealing process involves heating the material to a predetermined temperature, soaking at this temperature and slow cooling under a protective atmosphere or in air. Depending on the process parameters, we can distinguish between homogenizing, complete, normalizing, spheroidizing, recrystallizing and stress relieving annealing.

In the scope of annealing, we offer annealing with:

– slow cooling in a protective atmosphere

– slow cool in air atmosphere

– slow cool under vacuum

– slow or forced cool under nitrogen or argon

Tempering

Tempering is a heat treatment process consisting in heating the previously hardened steel to a certain temperature, withstanding and slow air cooling. The purpose of tempering is to remove the stresses created during hardening, to change the physical properties and, above all, to increase impact resistance at the expense of reduced hardness.

We can distinguish three types of tempering:

– Low tempering at 150-250°C, applied in order to reduce hardening stresses. It does not significantly influence hardness reduction.

– Average tempering at 250-450°C, applied in order to provide significant strength and elasticity while maintaining sufficient resilience and ductility.

– High tempering at 450-Ac1, applied in order to significantly reduce hardness and obtain good flexural properties.

Carbonitriding

It consists in simultaneous enrichment of the part’s case with carbon and nitrogen. It is a modified carburizing process, carried out at lower temperatures (775 – 900°C) and for a shorter time. The process is used to increase the wear resistance of lightly loaded, small-sized products. We offer carbonitriding in an enriched, protective carburizing atmosphere.

Gas carburizing

Gas carburizing is a thermo-chemical treatment consisting in heating steel parts to the temperature of 870 – 1000 ° C and heating them in a carburizing atmosphere. The purpose of carburizing is to enrich the surface layer with carbon and, as a result, increase its hardness and abrasion resistance while maintaining a ductile core. Directly after carburizing, hardening and tempering are most often carried out.

We offer carburizing in a protective atmosphere according to the following stages:

– Direct: (carburizing -> quenching -> tempering)

– Single: (carburizing -> slow cooling -> heating to austenitization temperature along with hardening -> tempering)

– With isothermal stop: (carburizing -> cooling down to the set temperature -> heating to austenitization temperature with quenching -> tempering)

– Double: (carburizing -> quenching -> heating to austenitizing temperature along with quenching -> tempering)

Single carburizing processes or with an isothermal stop are especially dedicated when it is necessary to perform, respectively: additional soft machining, austenite grain refinement (the so-called perlitization process).

Nitriding

Nitriding is another form of surface hardening of steels. It is a thermochemical process in a nitrogen-releasing environment. In this atmosphere the material is heated to a temperature between 475 and 550°C. The material is then held at this temperature for a certain time. This time can vary from a few minutes up to 120 hours. Eventually, the material is cooled down.

The desired hardness is created by the transfer of nitrides into the metal mesh. Different degrees of hardness can be achieved depending on the element used.

The characteristics of the process are:

- Low temperature between 475°C to 550°

- Flexibly applied – process duration modified according to the specification of the required final component properties.

- Environmentally friendly compared to serious alternatives (e.g. chrome plating).

- Clean for the component –g. leaving no heavy surface contaminant or residue

Nitrocarburizing

Nitrocarburizing is a process for surface hardening of materials. As a result of thermochemical diffusion, the surface layer of the material is enriched with nitrogen and carbon. In contrast to nitriding this is a process in which only nitrogen is deposited in the surface layer. The compound layer formed through nitrocarburizing is generally thicker, more corrosion resistant and often takes the form of Epsilon Iron Nitride.

Straightening

We have fully automated lines for straightening round and flat parts, as well as details of complex geometry (shafts, profiles). The lines are endowed in integrated sensor for internal crack detection.

– 160kN pressure force

– Workpiece lengths: 200-1000 mm

– Workpiece weight: 0.5-5 kg

– Straightening accuracy: up to 0,01 mm

Eddy current

A fully automatic crack detection device. The scope of application of the crack testing machine includes 100% testing of key safety components such as drive shafts, wheel hubs or brake discs. Non-destructive vortex tests are performed by fully scanning the electromagnetic fields of the respective areas to eliminate the presence of cracks in the details.

One of the most important elements in the heat treatment process is washing before and after the process. We are aware of that! That’s why we have high-performance chamber units for parts cleaning.

Water – Based

Cieffe WCF-8/2 / E-R – chamber cleaning device with two tanks for cleaning parts before the process. The advanced technology of used water-based detergents makes the details before the process perfectly washed, which has a decisive influence on the quality of the heat treatment while taking care of the environment.

Hydrocarbon – based

EMO VAIOCS – high-performance hydrocarbon cleaner for cleaning the right part after heat treatment. It is characterized by excellent degreasing (vacuum degreasing) and washing features, which plays a crucial role in the subsequent production steps, affecting the quality of the finished product surface.

Manual and automatic sandblasting machine MHG Strahlanlagen is available and characterizes by high performance and very good results of blasting the sandblasted parts.

Modern laboratory equipment enabling the implementation of:

– Sample preparation, including mounting and polishing

– Hardness measurement by the methods of Vickers, Rockwell, Brinell

– Measurement of microhardness with measurement of the hardened layer CHD and NHT Microstructure analysis

– Analysis of the chemical composition of the material using a spectrometer

We offer laboratory services as part of the heat treatment technology services and on individual orders.

downloads

certificates and management policy

general terms and conditions

our inhouse processes

Aalberts surface technologies in Dzierżoniów is your specialist for an excellent thermal or thermo-chemical heat treatment, with a focus on case hardening of driveline components (e.g.: tubular drive shafts).

We improve the surface and mechanical properties of your components for the long term, with specially developed processes and state-of-the-art plant technology.

industries we serve

contact & directions

Aalberts Surface Technologies Heat Sp. z o.o.

ul. Strefowa 5