polymer coating

Aalberts surface technologies Landsberg

about this location

welcome to Landsberg

In 1961 our company was founded in Starnberg, Bavaria. The headquarters was expanded in 1989 by the branch plant in Nidda-Borsdorf in Hessen and then in 1999 moved to Landsberg am Lech to further increase production capacity. We now proudly combine the advantages of a medium-sized company with those of a global corporation. Since 2016 we belong to Aalberts N.V. and since 2019 we have been carrying this outwardly through our new name.

We are still your “medium-sized company”; on site and not only distinguish ourselves by our flexibility and quality in order processing, but also by our personal contact with our customers. If we don’t offer your coating solution here at the site, our global structures will take effect: Aalberts surface technologiesis unbeatable with a huge portfolio of different surface treatment processes and plants worldwide. We offer you what you need. In addition to optical aspects of the coating, our surface coatings make some processes possible or significantly improve them: production and cleaning times are shortened, downtimes are reduced and the service life is extended. Auxiliary and operating materials can be omitted. Our location stands for the best polymer and nano coatings and also offers special services such as sandblasting and paint stripping. If components exceed our maximum dimension of 6 meters, our Nidda plant is the right partner for you.

our services

We are the right partner for both new parts business and component maintenance. In addition to offering various coating processes, our competence also includes partial coating of components and keeping technically necessary areas of the components free from coating. In individual areas we also offer light assembly steps after coating.

process overview

| process | max. size in mm | max. weight in kg |

| NANOFINISH® | 3300x900x900 | 500 |

| MagnaCoat® / SafeCoat® | 6000x2500x2450 | 6000 |

| TempCoat® / SafeCoat® | 6000x2500x2450 | 6000 |

| DELTAPROTEKT® | 6000x2500x2450 | 6000 |

| DELTASEAL® | 6000x2500x2450 | 6000 |

| DELTATONE® | 6000x2500x2450 | 6000 |

coating services

- Corrosion protection

- Non-stick coating

- Slide coating

- Wear protection

- Antimicrobial treatment

- Reduction in friction

- Reduction in noise

process services

- Wet painting

- Powder coating

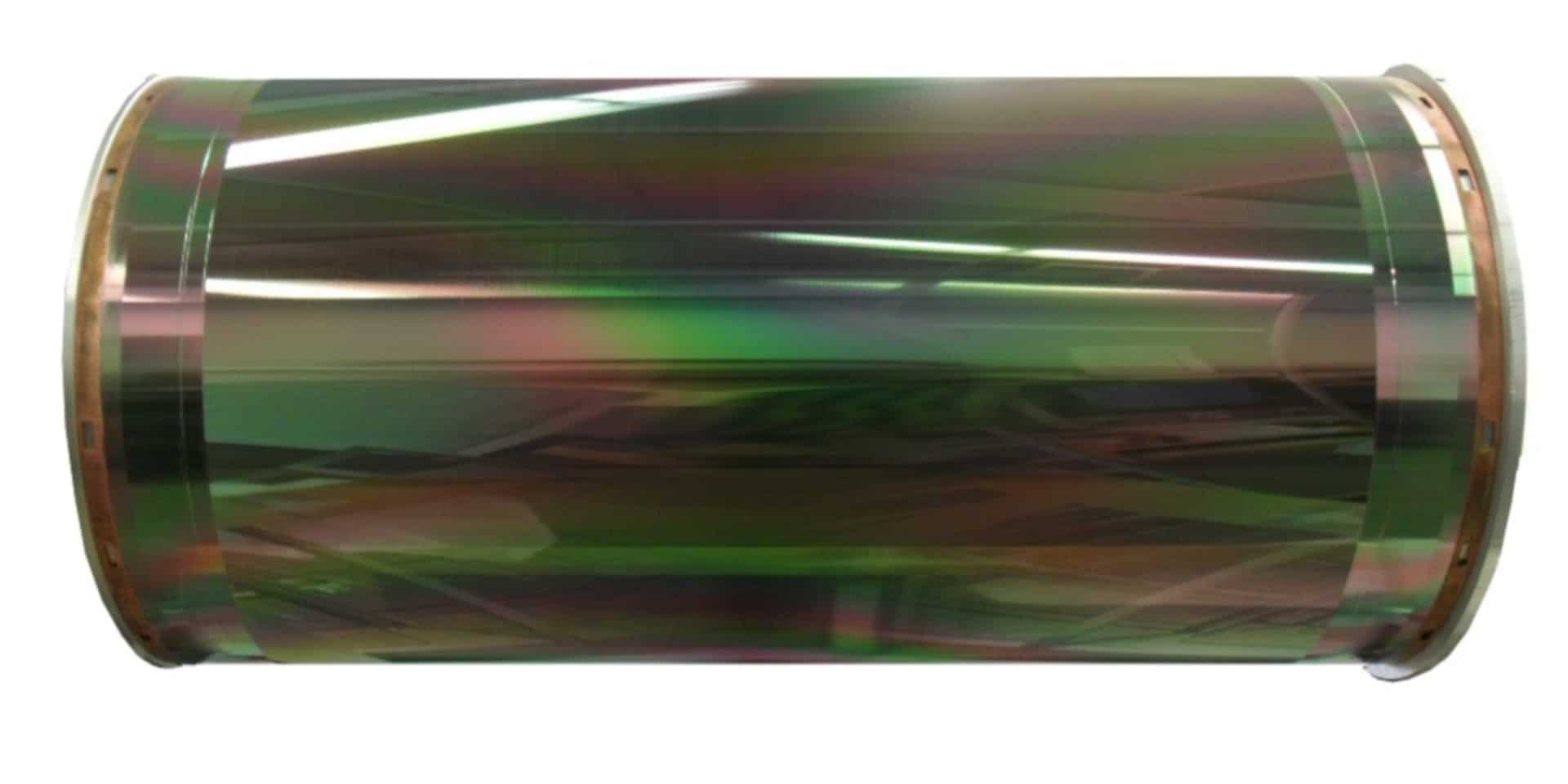

- Polymer coatings (PFA, FEP, Halar/ECTFE, EFTE, PTFE, PEEK, PE, Polyrethan)

- Vacuum coating

- Wet, powder and combination coating

special services

- Paint stripping

- Sandblasting

- Disassembly and assembly

quality and know-how

As a coating company certified by ISO, we guarantee optimal, reproducible quality – whether its machine components or serial parts. Quality, on-time delivery, precision and reliability are a matter of course. Our coatings are constantly being enhanced, allowing us to always find the ideal coating for the customer’s application. Our manufacturing processes follow the most modern production standards and meet all of the common industry requirements.

applications

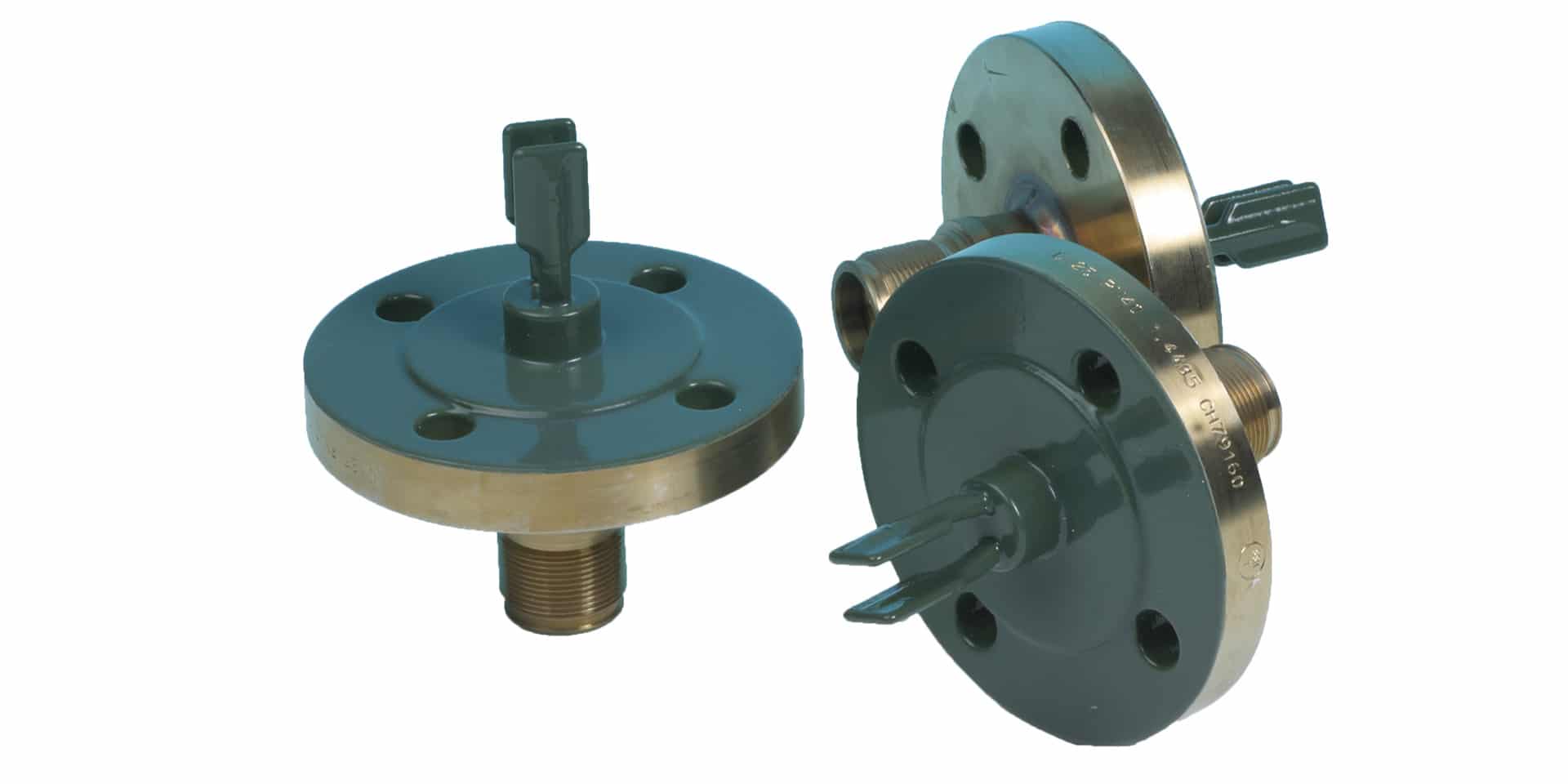

Chemical resistance, dry lubrication, sliding properties, resistance to wear, non-stick properties, resistance to impact and scratching, thick coatings are just a few of the features offered by our coating systems. They facilitate greater production output, quicker cleaning and less machine downtime. Whether pumps, pistons, fans, mixers, baking pans, chutes, rolls, screws, ink pans, glue tanks… – We work with you to find the ideal solution for your application.

non-stick coating

Thanks to material and environmentally friendly application processes such as polymer and nano-vacuum coatings, wet painting and powder coating from Landsberg, the components have long-lasting properties. MagnaCoat® and TempCoat® (formerly known as ChemCoat® and SafeCoat®), HCP zinc flake and nanocoating: these product families offer a range of proven solutions to optimize applications.

downloads

Aalberts surface technologies offers security. We want to offer you the greatest possible security. That is why our Aalberts surface technologies sites are certified.

certificates

general terms and conditions

our inhouse processes

We are the right partner for both new parts business and component maintenance. In addition to offering coatings like vacuum coatings, wet painting, polymer coatings and nanocoatings, our competence also includes partial coating of components and keeping technically necessary areas of the components free from coating.

industries we serve

contact & directions

Aalberts Surface Technologies GmbH