wet painting

what is wet coating?

Wet coating is a popular and widely used coating technique suitable for almost all substrates. This spraying process allows for a wide range of effects, surface structures and color variations. No matter if we are talking about small parts, like washers, or large prototypes: Aalberts surface technologies coats all workpieces which can be transported by road.

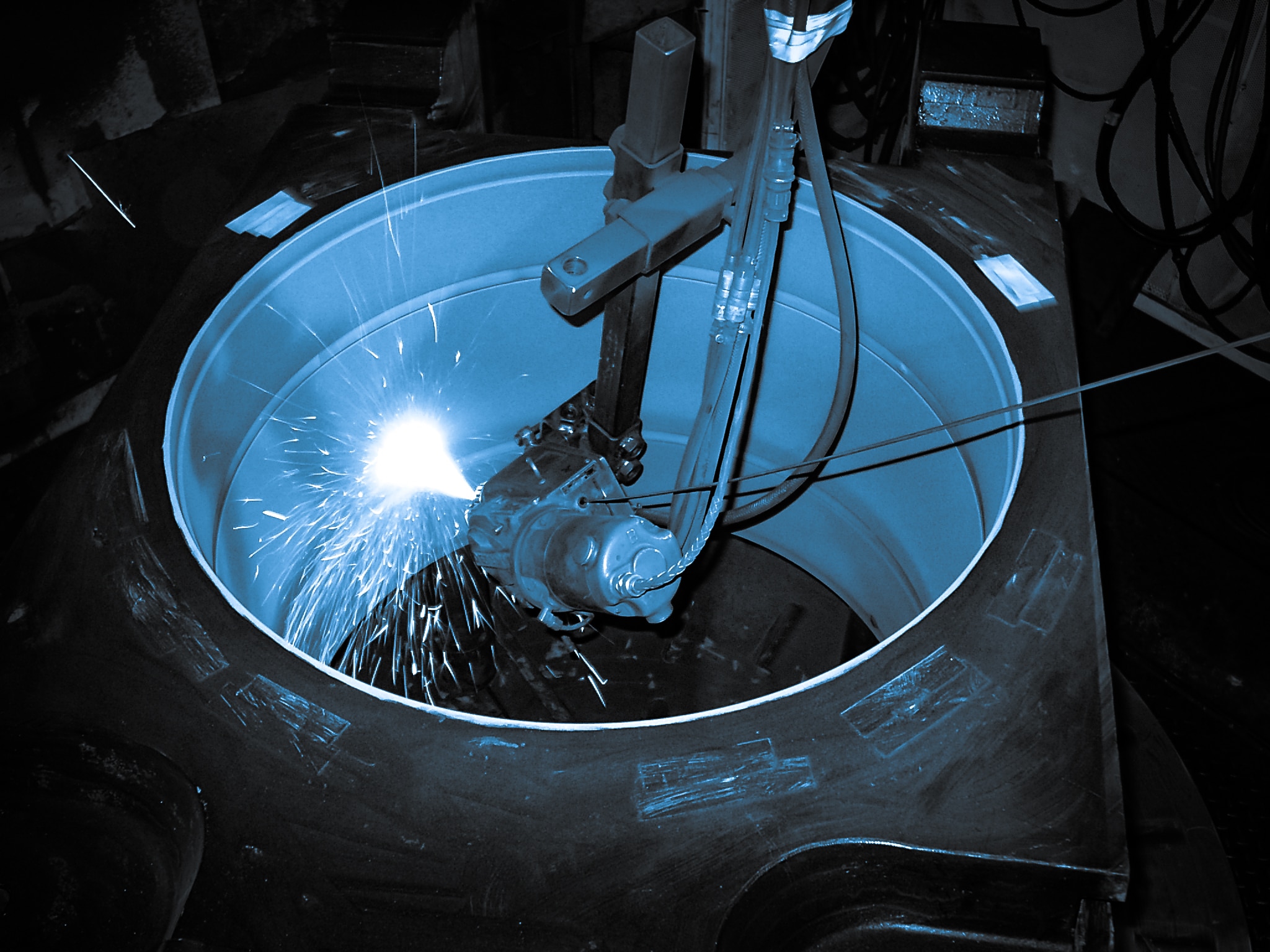

this is how our wet coating processes look like

With our high-performance wet coating systems, polymer coatings, primers and lubricant films, we have expanded our range of services to include useful follow-up treatments so that you can save both time and money. The following applies to many industrial coatings: The time for subsequent process steps is limited. By taking care of the coating and finishing processes, we can guarantee the fulfillment of these requirements – and avoid additional packaging and transport costs as well as delays.

By combining suitable coatings with matching anodized or conversion coatings, the achievable improvements are not limited to surface protection. With the help of wet coating processes, designers can have their components finished in different colors or have them marked and treated with further surface finishes. What is more, the selective application of coatings with masking and localized spraying makes it possible to deliver finished parts which are ready for being assembled. We use techniques such as wet-on-wet coating and mechanical rework to increase our surface coatings’ efficiency and functionality even further.

properties of wet coating processes

We offer a wide range of wet coatings which are applied to components with the aim of increasing their performance in certain situations. Wet coating processes are ideal for customization. We perform them manually, with the assistance of robots or in conveyor systems to create, for example, the following effects:

- Reduced friction welding

- Increased gliding properties

- Protection against high temperatures

- Improved resistance to chemicals

- Creation of non-stick properties

- Improved cleanability

basic materials suitable for wet coating

When it comes to our wet coating processes, we currently focus on anodized or other coated components made from aluminum alloys, steel alloys and titanium materials. The drying temperature of the used coatings ranges from 50°C to 100°C – temperatures which almost all materials can withstand. In general, our wet coating processes are able to create decorative surfaces on almost all substrates.

fields of application of wet coatings

Our wet and lubricant coatings are much sought after in the aerospace industry, in defense technology and in the automotive industry. However, we also have special equipment for the coating of exceptionally large steel structures, such as bridge or crane components or dolphins for harbors. We can apply our high-quality anti-corrosion and fire-retardant coatings to everything that rolls into our halls by road transport.

Your workpieces are difficult to transport or need to be operational immediately after coating? If so, please do not hesitate to get in touch with us. We offer custom solutions which can be implemented at your premises.

industries we serve

frequently asked questions

It is possible to create the full range of RAL colors with wet coating.

We can coat components in dimensions of 3x3x30 m (height/width/length). However, smaller components are equally well suited for wet coating.

Wet coating is a highly customizable process, and there are certified coating systems available for the highest corrosivity classes.

Wet coating improves the component’s resistance to chemicals and protects against high temperature loads. Even geometrically complex components are suitable for wet coating. They can be treated to offer effective and long-lasting protection against corrosion and fire.

Basically, our wet coating processes are suitable for almost all substrates, and thus also for anodized parts.

At Aalberts surface technologies, solvent-based coatings or water-based coating systems are applied in spray booths with wet and dry separation combined with heat recovery and exhaust air purification.

process locations

Any questions? Contact us directly or select a process location near you.

Landsberg am Lech

Germany 48.068575810.8542243 landsberg@aalberts-st.com +49 8191 91186 10 show locationPulversheim

France 47.8338557.301753 pulversheim@aalberts-st.com +33 389 2832 80 show locationSolingen

Germany 51.20048227.0787766 solingen@aalberts-st.com +49 212 25834 0 show locationTatabánya

Hungary 47.582185518.3456132 tatabanya@aalberts-st.com +36 34 5146 70 show locationLübtheen

Germany 53.26711911.088846 rfq@i-process-techonologies.com +49 37754 505 23 to locationUnsere Verfahren

Wir bieten weltweit alle Arten von Wärmebehandlungsprozessen an. Unsere Anlagen sind logistisch eng miteinander verknüpft, so dass Ihnen alle Verfahren zur Verfügung stehen. Erfahren Sie mehr zu unseren Wärmebehandlungsverfahren.

Heiß-Isostatisches Pressen (HIP) dient der Beseitigung von Porosität. Sie benötigen bei Lötverbindungen eine hohe mechanische Haltbarkeit und Unempfindlichkeit bei hohen Temperaturen? Wir bei Aalberts surface technologies bieten die Lösung durch Hartlöten (brazing).

Polymerbeschichtungen können auf viele Grundmaterialien aufgebracht werden und bieten lang anhaltenden Schutz. Sie sind mechanisch besonders gut mit dem Untergrund verankert und bieten verbesserte Gleiteigenschaften und/oder hohe Verschleißfestigkeit.

Mit 40 Jahren Erfahrung in der kontinuierlichen Veredelung von reel to reel können Sie sich auf Aalberts surface technologies verlassen, um innovative Lösungen zu finden. Unser Service umfasst Trommelgalvanik, kontinuierliche selektive Galvanik und Gestellgalvanik.

Fast alle metallischen Grundwerkstoffe können mit unseren selbstentwickelten und patentierten Verfahren durch Oberflächenbeschichtungen in ihren Eigenschaften optimiert werden, egal ob sie besonders hart, glatt, verschleißfest oder korrosionsbeständig sein sollen.

Discover our services

We offer all types of heat treatment processes. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. For a complete list and description of heat treatment technologies please select the button.

Hot isostatic pressing (HIP) is used to eliminate porosity. Do you need high mechanical durability and insensitivity to high temperatures for solder joints? We at Aalberts surface technologies offer the solution through brazing.

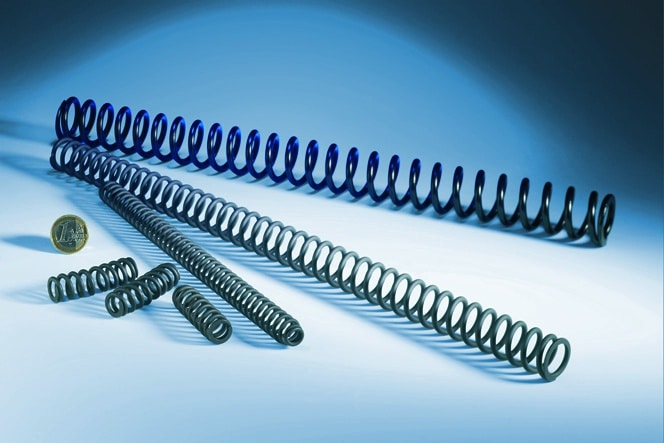

Polymer coatings can be applied to a wide variety of base materials and offer long-lasting protection. They are particularly well anchored mechanically to the substrate. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance.

With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. Our service includes barrel plating, continuous selective plating and rack plating.

Almost all metallic base materials can have their properties optimised by surface coatings using our proprietary and patented processes, regardless of whether they should be particularly hard, smooth, wear-resistant or corrosion-resistant.

The Aalberts websites use cookies (read more) to analyse website usage and improve usability. We also use third party tracking-cookies to measure user preferences, enable content sharing on social media and interest-based advertising. If you hit 'accept' you allow to us to place the different types of cookies.

privacy overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |