small structures with a major effect

nanocoatings

what is nanocoating?

nanocoatings: Innovative premium coatings with a major effect

NANOFINISH® as infiltration-resistant nanocoating

fields of application of NANOFINISH®

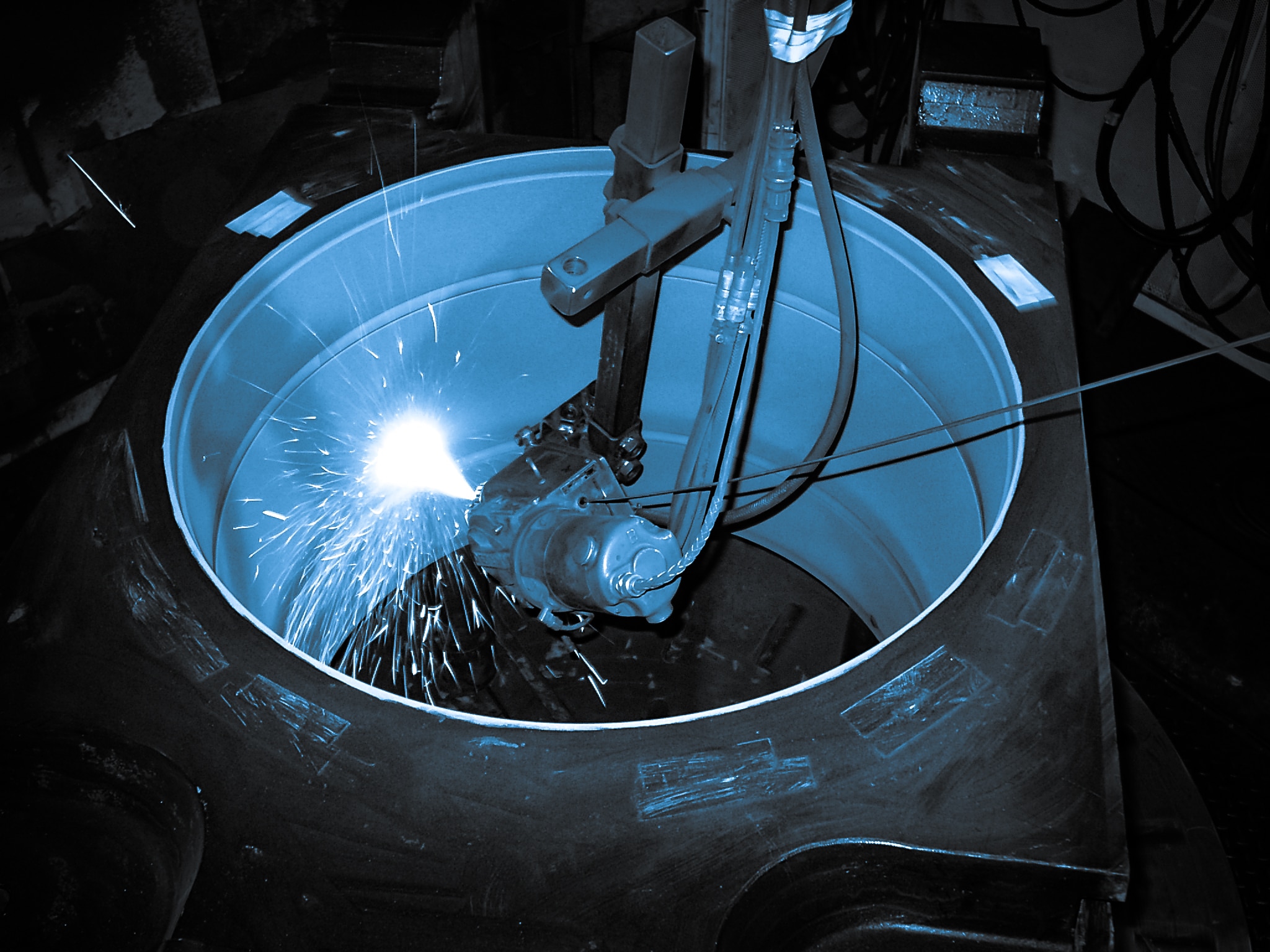

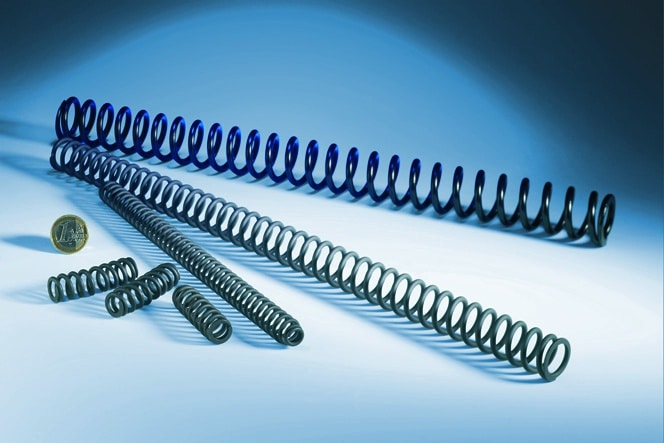

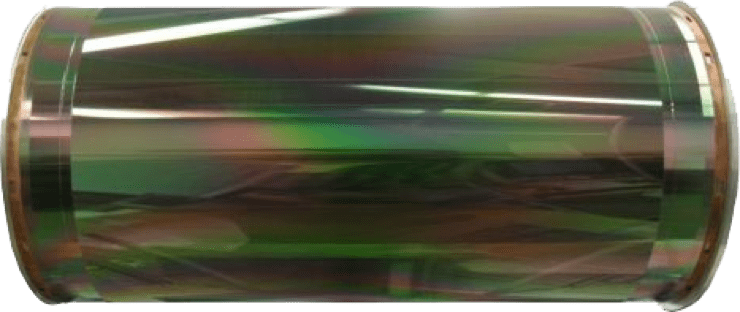

Finely structured nanoscale coatings are particularly suitable for fine-pored parts and high-precision applications. Nanotechnology in the form of extremely thin non-stick coatings is used in the area of demolding or as a protective layer for the sealing of many different surfaces. This highly performing nanocoating is also suitable for molds used in the electronics and medical technology industries. What is more, NANOFINISH® offers excellent corrosion protection for a wide range of applications where precision and continued functionality are required.

industries we serve

frequently asked questions - nanocoatings

process locations

Landsberg am Lech

Germany 48.068575810.8542243 landsberg@aalberts-st.com +49 8191 91186 10 show locationTamworth

United Kingdom 52.6419852-1.7146314 tamworth-oct@aalberts-st.com +44 1827 634 89 show locationUnsere Verfahren

Wir bieten weltweit alle Arten von Wärmebehandlungsprozessen an. Unsere Anlagen sind logistisch eng miteinander verknüpft, so dass Ihnen alle Verfahren zur Verfügung stehen. Erfahren Sie mehr zu unseren Wärmebehandlungsverfahren.

Heiß-Isostatisches Pressen (HIP) dient der Beseitigung von Porosität. Sie benötigen bei Lötverbindungen eine hohe mechanische Haltbarkeit und Unempfindlichkeit bei hohen Temperaturen? Wir bei Aalberts surface technologies bieten die Lösung durch Hartlöten (brazing).

Polymerbeschichtungen können auf viele Grundmaterialien aufgebracht werden und bieten lang anhaltenden Schutz. Sie sind mechanisch besonders gut mit dem Untergrund verankert und bieten verbesserte Gleiteigenschaften und/oder hohe Verschleißfestigkeit.

Mit 40 Jahren Erfahrung in der kontinuierlichen Veredelung von reel to reel können Sie sich auf Aalberts surface technologies verlassen, um innovative Lösungen zu finden. Unser Service umfasst Trommelgalvanik, kontinuierliche selektive Galvanik und Gestellgalvanik.

Fast alle metallischen Grundwerkstoffe können mit unseren selbstentwickelten und patentierten Verfahren durch Oberflächenbeschichtungen in ihren Eigenschaften optimiert werden, egal ob sie besonders hart, glatt, verschleißfest oder korrosionsbeständig sein sollen.

Discover our services

We offer all types of heat treatment processes. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. For a complete list and description of heat treatment technologies please select the button.

Hot isostatic pressing (HIP) is used to eliminate porosity. Do you need high mechanical durability and insensitivity to high temperatures for solder joints? We at Aalberts surface technologies offer the solution through brazing.

Polymer coatings can be applied to a wide variety of base materials and offer long-lasting protection. They are particularly well anchored mechanically to the substrate. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance.

With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. Our service includes barrel plating, continuous selective plating and rack plating.

Almost all metallic base materials can have their properties optimised by surface coatings using our proprietary and patented processes, regardless of whether they should be particularly hard, smooth, wear-resistant or corrosion-resistant.

The Aalberts websites use cookies (read more) to analyse website usage and improve usability. We also use third party tracking-cookies to measure user preferences, enable content sharing on social media and interest-based advertising. If you hit 'accept' you allow to us to place the different types of cookies.

privacy overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |