polymer coating

Aalberts surface technologies Solingen

about this location

welcome to Solingen

In the north of Solingen you will find our factory premises. Our qualified employees work here to protect your components with the help of innovative coating methods. Our surface finishing processes in Solingen protect against corrosion and wear in order to reduce costs and increase the efficiency and quality of your production.

With our plant in Dycker Feld, we have established ourselves in the region and beyond through our services in the field of surface technology – since 2000 as part of AHC Oberflächentechnik GmbH and now since 2019 as a member of the Aalberts family. Our customers, who, for example, are rooted in the automotive and construction industries, appreciate the guarantee of high quality standards, individual technical advice and punctual delivery.

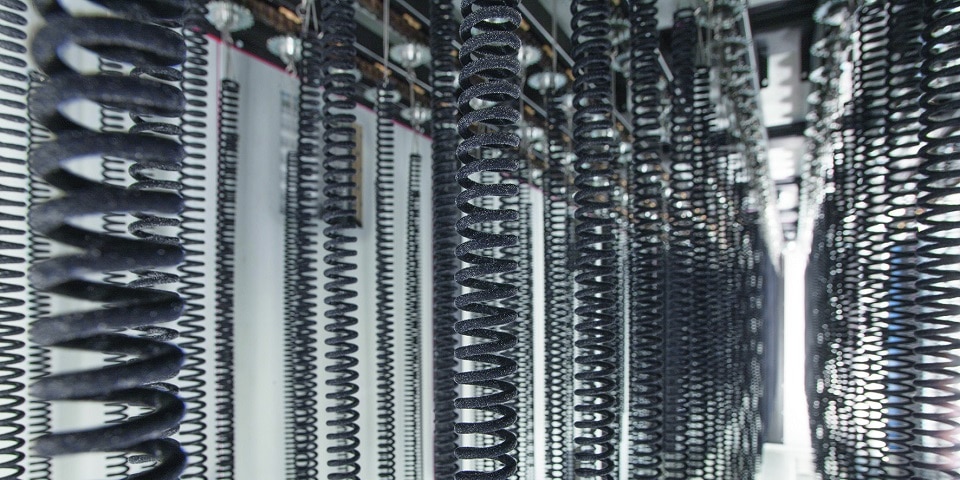

The major focus of the coating processes at the Solingen site is on dry-lubricating anti-friction coatings, which are well-known on the market under the name GLISS-COAT®. They ensure optimal sliding behavior of technical components, increase their corrosion and wear resistance and minimize unwanted noise such as creaking and squeaking. Phosphating as well as cathodic dip painting and the coating of circular symmetric components are additional segments of our comprehensive range of services.

“We are a competent partner and problem solver for our customers and we are proud to live this philosophy within Aalberts surface technologies.”

Miguel Rodrigues, plant manager

process overview

| process | max. size in mm | max. weight in kg |

| GLISS-COAT® | 1700x800x500 | 10 |

| GLISS-COAT® green | 1700x800x500 | 10 |

| GLISS-COAT® FLOCK | 1300x600x100 | 10 |

| PPG XYLAN® 1010 | on request | 2,5 |

| Wet paint | on request | on request |

| Cathodic dip painting | 1000x1000x600 | 1 (piece weight) |

| Zinc phosphating | 1000x1000x600 | 250 |

dry lubrication

From the point of view of the technical application, dry lubrication is a grease-free, low-maintenance lifetime lubrication for reducing the coefficient of friction and simultaneously reducing noise. The basis of dry lubrication is formed by solid lubricants such as PTFE, MoS2 or graphite, which we integrate into an environmentally friendly aqueous coating system. Aalberts Surface Technologies GmbH Solingen offers the key to this in the form of environmentally friendly and innovative product developments from the GLISS-COAT®, GLISS-COAT® green and GLISS-COAT® FLOCK ranges.

GLISS-COAT® coatings are permanent sliding coatings on whose surface a sliding film with constantly low coefficients of friction is formed. They offer friction coefficient and noise reduction in combination with wear and corrosion protection to functionalize your surfaces.

- Functional coating of solid lubricants embedded in a synthetic resin matrix

- Constant sliding film of dry lubricants

Environmentally friendly system through the use of water-based coatings

Functional coating for maintenance-free permanent lubrication

- Grease-free, low-maintenance lifetime lubrication

- Wear reduction with simultaneous noise reduction

- High process reliability due to constantly low coefficients of friction

- High corrosion resistance through pretreatment with cathodic dip coating

The PPG XYLAN® 1010 coating we offer is a solvent-based, resin-bonded, temperature-resistant sliding coating formulated to reduce the coefficient of friction. PPG XYLAN® 1010 provides an optimum low friction to wear ratio. Suggested end-use applications include valves and actuators.

our coating services

- Noise reduction

- Friction coefficient reduction

- Corrosion protection

- Wear protection

- GLISS-COAT® → self developed slide coatings

- GLISS-COAT® FLOCK → manual and automated flocking system

- GLISS-COAT® green

- PPG XYLAN® 1010 → Application to round symmetrical components with partially automated processes

- Around injection application → competence center (Anker)

- Cathodic Dip Painting: CPD-Coating und phosphating

- Combined coatings

special services

For our customers we assemble components and package them according to customer specifications. In addition, special combination coatings are used also based on pre-coatings by our sister sites at Aalberts surface technologies.

- Corona flame

- Corona plasma

- Degreasing

- Combined coatings

- Phosphating

- Sandblasting

GLISS-COAT® - self developed slide coatings

GLISS-COAT® is a self-developed, dry-lubricated slide coating to reduce friction and wear. The coating material is water-based and can be applied in various spray applications.

GLISS-COAT® green the PFAS-free solution for your surface

The newly developed GLISS-COAT® green systems are not only PFAS-free, but the use of the latest composite polymers has further increased the service life in the application as well as the reduction of friction values compared to their PFAS-containing predecessors.

GLISS-COAT® FLOCK - manual and automatic flocking system

GLISS-COAT® FLOCK is a coating developed to increase the absorption capacity for impacts and noises. To achieve this a lubricious GLISS-COAT® adhesive is combined with polymer fibers.

GLISS-COAT® FLOCK can be applied to phosphated, anodized and blasted metal surfaces, as well as on plastic.

cathodic dip painting (KTL) - for high quantities and complicated textures

KTL (cathodic dip painting) is a process in which the workpiece to be coated is negatively charged through electricity and dipped into a paint bath with positively charged paint particles. These particles are attracted by the workpiece, deposited on it and form a uniform film over the entire surface. After application of the coating layer, heat treatment (baking) is carried out at 180 to 220 °C. The coating is then applied to the workpiece (in an automatic batch line).

Daimler:

- DBL 7390

- DBL 7381

- DBL 7382

- DBL 7391

VW:

- VW TL 260 Ofl-x-634

- VW TL 260 Ofl-x-630

- VW TL 262 Ofl-x-635

- VW TL 227 Ofl-x-633 KTL

Honda:

- HES D2021-07 Class 1 Grade 4

MAN:

- MAN Nutzfahrzeuge AG Werknorm M3078

- MAN 3018

BMW:

- BMW GS 90011, Anführungsgruppe LASW 3

- BMW AA0055

Toyota:

- Toyota TSH 2354G

Ford:

- Ford WSK-M2P-153

individual coating of round symmetrical components - application of anti-friction coatings on circular spraying machines

We in Solingen, Germany, are the competence center for the coating of round symmetrical components with bonding coatings. Armatures for solenoid valves for switching and braking systems for motor vehicles are such components. The coating is applied uniformly within narrow tolerances. Partial coatings with the water- and solvent-based bonded coating systems are also possible.

quality & know-how

We are your competent partner for surface treatment in Solingen and throughout Germany. In order to guarantee consistently high quality, we are regularly certified according to ISO standards. Regardless of your order volume or type of component, we promise on-time delivery, precision and a high standard. With our many years of experience in the field of surface technology, our specialists are constantly working to further improve proven processes or to develop innovative new coatings – always according to your wishes as our customers or according to the requirements of certain industries.

applications

Depending on the process variant, all technically interesting metals, light metals and plastics can be coated to enable low-slip or noise-reduced applications for the customer.

areas of application

Our various processes find suitable use on all parts which are exposed to a high frictional load or where the coating of components requires a certain functionality and/or corrosion protection, e.g. movable vehicle interior components, closing components, hinge pins, bearing pins as well as approximately symmetrical components and helical compression springs for damping systems. In many cases a replacement for grease and lifetime lubrication.

downloads

Aalberts surface technologies offers security. We want to offer you the greatest possible security. That is why our Aalberts surface technologies sites are certified.

certificates

general terms and conditions, company policy and brochures

our inhouse processes

We are the right partner for anti-friction coatings and cathodic dip painting. In addition to offering various coating processes, our competence also includes partial coating of components and keeping technically necessary areas of the components free from coating. In individual areas we also offer light assembly steps after coating.

industries we serve

contact & directions

Aalberts Surface Technologies GmbH