surface treatment

Aalberts surface technologies Weiterstadt

about this location

welcome to Weiterstadt

Founded in 1983 in the Hessian city of Weiterstadt, our factory has gone through a remarkable development based on the continuous enhancement of our expertise and services. Centrally located just 2 km away from the A5 motorway access, our location can be easily reached. When it comes to functional surface finishes, we are your expert partner in the areas of aluminum electroplating and electroless nickel plating for aluminum, steel and non-ferrous metals. Fully automated processes are performed using state-of-the-art plant technology. In November 2012, we put Europe’s largest electroless nickel plating plant for series and small parts into operation. We have since been able to successfully implement many projects involving large-volume applications.

our surface finishing services in Weiterstadt:

process overview

| process | max. size in mm | max. weight in kg |

| Anodizing colorless (only cold) | 2300x1350x650 | 1000 |

| HART-COAT® colorless | 2300x1350x650 | 1000 |

| HART-COAT® HC-GL | 2300x1350x440 | 1000 |

| DURNI-COAT® DNC 471-AL lead-free | 1500x1100x600 | 1500 |

| DURNI-COAT® DNC 571-AL lead-free | 1500x1100x600 | 1500 |

| DURNI-COAT® DNC 771-AL | 1500x1100x600 | 1500 |

| PTFE-DURNI-DISP | 1500x1100x600 | 1500 |

| SIC-DURNI-DISP | 1500x1100x600 | 1500 |

| DURNI-COAT® DNC 471 lead-free | 1500x1100x600 | 1500 |

| DURNI-COAT® DNC 571 lead-free | 1500x1100x600 | 1500 |

| DURNI-COAT® DNC 771 lead-free | 1500x1100x600 | 1500 |

coatings

Anodic coating (aluminum only – all alloys):

- HART-COAT® with variations for cast and copper-based alloys

- HART-COAT®-GLATT (HC-GL)

- Technical anodizing

Electroless nickel plating:

- DURNI-COAT® 471 (high-phos.)

- DURNI-COAT® 571 (mid-phos.)

- DURNI-COAT® 771 (low-phos.)

- PTFE-DURNI-DISP (tribology: reduced friction)

- SIC-DURNI-DISP (tribology: increased friction)

Herewith we comply with the information obligation for SVHC substances within the supply chain according to article 33 of the REACH regulation (EG) 1907/2006 and point out that the amount of lead present in SIC-DURNI-DISP layers is above the limit value of 0.1 mass %.

Please take this information into account for your further evaluation according to REACH regulation.

As a result, the SIC-DURNI-DISP process is not RoHS compliant.

According to Directive 2011/65/EU, this coating may not be used in electrical and electronic equipment with RoHS requirements.

coating characteristics

- Wear protection

- Corrosion protection

- Increased hardness

- Improved gliding behavior

services

- Service Center for technical advice / sampling processes

- In-house laboratory with comprehensive metallographic Equipment

- 100% control department for checking critical features and safety-relevant components

- 100% traceability from the goods’ arrival to their handover to the forwarding company

- Customer-oriented storage of large series

- 2 halls with more than 600 storing positions for the storage of raw and finished goods

quality and know-how

applications

fields of use

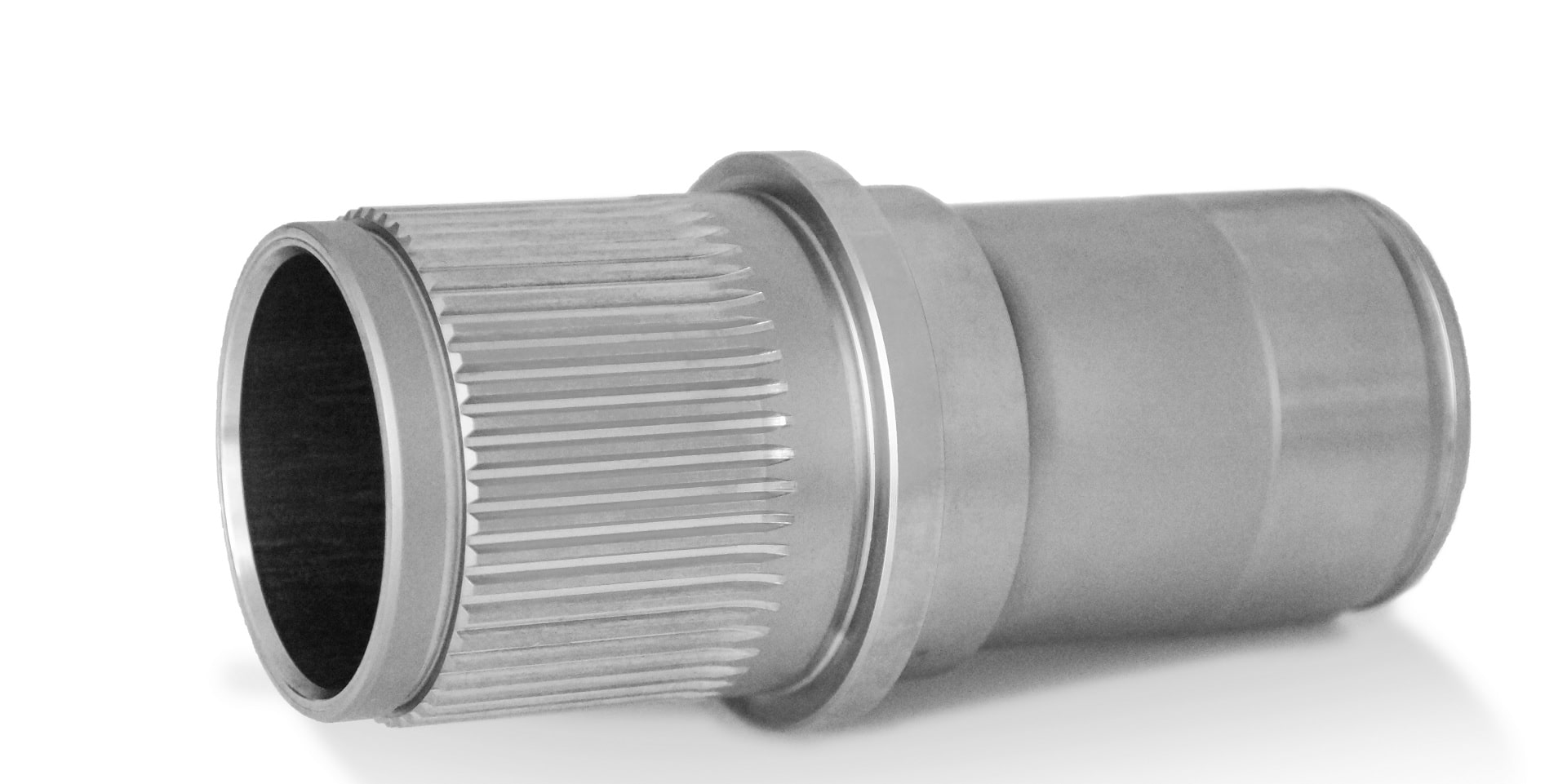

At our Weiterstadt location, we offer you HART-COAT®, HART-COAT®-GLATT (HC-GL) and technical anodizing as well as several electroless nickel plating variants, the entire range of phosphorus classes and 2 special processes for influencing the coefficient of friction. The applications and fields of use of our solutions are versatile: PTFE-DURNI-DISP is used, for example, for coating armatures for solenoid switches. The coating protects the components against corrosion and improves their gliding behavior so that the switches can function without delays. SIC-DURNI-DISP is used on pump housings, pump wheels or grippers for the transport of paper, i.e. wherever high wear resistance is of paramount importance. Whereas our HC-GL coating comes into play, for example, for aluminum pump components used for the dosing of AdBlue. AdBlue, which is used for exhaust gas treatment in the automotive sector, would attack non-coated aluminum.

downloads

Aalberts surface technologies offers security. We want to offer you the greatest possible security. That is why our Aalberts surface technologies sites are certified.

certificates

general terms and conditions

our inhouse processes

We are the right partner for both new parts business and component maintenance. In addition to offering anodizing, electroless nickel plating and hard anodizing, our competence also includes partial coating of components and keeping technically necessary areas of the components free from coating.

industries we serve

contact & directions

Aalberts Surface Technologies GmbH