thin and yet top-performing coatings

vacuum coatings

what is a vacuum coating process?

In the vacuum coating process, metallic or ceramic coatings are deposited in a vacuum system with a layer thickness of a few micrometers, in some cases even just nanometers.

Our coatings are based on two advanced finishing processes: cathodic arc evaporation and plasma-assisted chemical vapor deposition.

cathodic arc deposition

Cathodic arc evaporation is one of the PVD processes (physical vapor deposition). In this process, metal (e.g. chromium or titanium) is vaporized using an electric arc and the metal vapour is ionized. These metal ions are then accelerated onto the workpiece at high speed in an electric field. They condense as a thin film on the component to be coated and form a very firmly adhering protective layer on the workpiece.

Ceramic coatings based on carbide, oxide or nitride are produced by adding reactive gases. Their hardness is over 100 HRC, well above that of hardened steels. This gives steel components a quasi-ceramic character. PVD coatings are therefore a cost-effective alternative to fully ceramic components. The best-known representative of these coatings is the titanium nitride coating known from the golden drills.

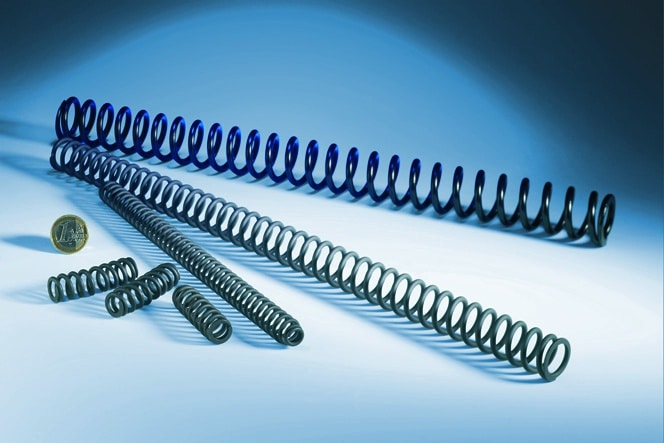

These extremely hard hard material coatings, which are only a few micrometers thick, are the perfect finish coatings for tools and components of all kinds, i.e. they do not require any post-processing. The edge build-up familiar from electroplated coatings does not occur and the workpiece geometries are reproduced with contour accuracy. Such coatings are therefore ideal for wear and corrosion protection, as non-stick coatings and for reducing friction in high-performance components.

As part of a hydrogen technology project, an innovative inline PVD coating process was developed for PTLs (porous transport layers) and bipolar plates. The aim was to achieve a high-precision precious metal nanocoating with platinum and other precious metals using physical vapor deposition (PVD).

The initial situation presented a considerable challenge: The customer needed a reproducible and scalable coating solution that minimized the use of precious metals without compromising electrochemical performance. The previous batch processes proved to be economically inefficient for industrial quantities.

The technical objectives of the project included the development of an inline-capable PVD process with a high throughput rate, a uniform layer thickness of less than 30 nm with high adhesive strength, and a reduction in precious metal consumption while maintaining electrochemical activity. High layer thickness homogeneity, precious metal deposition of less than 0.05 mg/cm², and a process time suitable for series production were defined as key performance indicators.

An inline PVD process with rotating substrate holders and optimized target utilization was developed for implementation. The coating technology contributed to improved adhesion, while precise process control was ensured by layer thickness measurement using XRF (X-ray fluorescence analysis). Process development was carried out in close cooperation with customers and plant manufacturers. The results were validated by electrochemical tests such as cyclovoltammetry (CV) and ICE resistance measurements (interfacial contact resistance).

Result: The precious metal application was reduced to less than 0.05 mg/cm² for a coating area of 1100 x 780 mm (with limitations up to 1600 mm). The developed inline process was successfully transferred to series production.

It was shown that our inline PVD coating enables scalable and cost-efficient production of high-performance PTLs and bipolar plates for PEM electrolysers. For the future, we plan to expand the process to other products and continue optimizing it to further reduce costs and increase capacity to over 1 GW (coated electrolyzer power).

plasma-enhanced chemical vapor deposition (PECVD = Plasma Enhanced Chemical Vapour Deposition)

Plasma-enhanced chemical vapor deposition is a coating process in which the chemical deposition of reactive gases is supported by a plasma. The plasma acts as a catalyst for the reaction of the reactive gases to form a thin layer on the surface of the workpiece at temperatures below 200°C, which means that the temperature load on the component is significantly lower than with conventional chemical vapor deposition (CVD).

This technology is ideal for producing extremely hard diamond-like carbon (DLC) coatings.

properties and possible applications of PVD and PECVD coatings

Our coatings can solve a wide range of problems on components and tools of all kinds:

- Wear protection

- Corrosion protection

- Reduction of friction coefficients

- High electrical conductivity

- Oxidation protection

- Anti-stick effect

- High IR reflection

- Allergy reduction

- Biocompatibility

- Catalytic soot prevention

- and much more.

Our innovative coating processes cover a wide range of possible applications. This is why our coatings are used in many different industries.

In the new hydrogen technology, they increase the conductivity of bipolar plates and PTL/GDL in fuel cells and electrolyzers and protect them from long-term degradation.

In combustion engines, for example, they are now used in series production on piston pins and rings, in valve trains and on transmission components.

Our globally unique cerid® 5N coating also prevents soot deposits on vehicle valves.

In medicine, our biocompatible allergy-reducing coatings have been used on implants and surgical instruments for over 30 years and help to sustainably improve patients’ quality of life every day.

NANOFINISH® – corrosion-resistant nanocoating

NANOFINISH® is an ultra-thin, non-stick nanocoating that remains stable even when damaged. Gases and liquids cannot penetrate the coating, so any defects stay localized without spreading. The contour-conforming layer is ideal for high-precision applications and polished surfaces. Whether used for demolding, as a protective film, or for sealing, NANOFINISH® provides reliable corrosion protection and long-lasting performance on nearly all substrates – for example, in electronics and medical technology.

benefit from our services, from the idea to series production:

- We develop individual solutions together with you

- Support from the idea to series production

- First-class customer care

- Highest quality – from small to large series

- Certified according to DIN EN ISO 9001:2015, VDA 6.1:2016 and ISO 13485:2016

downloads

industries we serve

frequently asked questions - vacuum coatings

WHAT ARE PVD COATINGS?

PVD stands for Physical Vapor Deposition. This method creates hard ceramic layers on the material which are only a few µm thick. These coatings are created in a plasma vacuum process.

WHY IS IT THAT VACUUM COATING TECHNIQUES ACHIEVE THE BEST RESULTS WHEN IT COMES TO THIN COATING THICKNESSES?

Thin coatings are true surface finishes which do not require any rework.

WHY DO VACUUM COATINGS PLAY A PARTICULARLY IMPORTANT ROLE IN THE AREA OF MEDICAL TECHNOLOGY?

When it comes to medical devices, vacuum coatings offer advantages like accurate contours and allergy-reducing surfaces. They are applied, for example, to dental, knee and hip implants.

ARE VACUUM COATINGS SUITABLE FOR TOOLS SUBJECT TO HEAVY LOADS?

Highly stressed forming tools and molds used in the areas of metal forming and plastic injection molding as well as all kinds of components are protected against wear, adhesion and corrosion. The tools’ service life is thus increased by factors between 3 and 10.

WHAT ARE THE STRENGTHS OF VACUUM COATING PROCESSES?

Vacuum coating processes create extremely pure and very thin layers. Thanks to these properties, vacuum coatings can also be used in sensitive areas, such as medical technology.

process locations

Any questions? Contact us directly or select a process location near you.

Kirkby-In-Ashfield

United Kingdom 53.1043759-1.2474762 nottingham@aalberts-st.com +44 1623 753 107 show locationLandsberg am Lech

Germany 48.068575810.8542243 landsberg@aalberts-st.com +49 8191 91186 10 show locationLübeck

Germany 53.8989610.79366 luebeck@aalberts-st.com +49 451 39006 0 show locationTamworth

United Kingdom 52.6419852-1.7146314 tamworth-oct@aalberts-st.com +44 1827 634 89 show locationWoonsocket (Rhode Island)

United States 41.998443-71.4767334 info@aalberts-st.us +1 401 766 3353 show locationUnsere Verfahren

Wir bieten weltweit alle Arten von Wärmebehandlungsprozessen an. Unsere Anlagen sind logistisch eng miteinander verknüpft, so dass Ihnen alle Verfahren zur Verfügung stehen. Erfahren Sie mehr zu unseren Wärmebehandlungsverfahren.

Heiß-Isostatisches Pressen (HIP) dient der Beseitigung von Porosität. Sie benötigen bei Lötverbindungen eine hohe mechanische Haltbarkeit und Unempfindlichkeit bei hohen Temperaturen? Wir bei Aalberts surface technologies bieten die Lösung durch Hartlöten (brazing).

Polymerbeschichtungen können auf viele Grundmaterialien aufgebracht werden und bieten lang anhaltenden Schutz. Sie sind mechanisch besonders gut mit dem Untergrund verankert und bieten verbesserte Gleiteigenschaften und/oder hohe Verschleißfestigkeit.

Mit 40 Jahren Erfahrung in der kontinuierlichen Veredelung von reel to reel können Sie sich auf Aalberts surface technologies verlassen, um innovative Lösungen zu finden. Unser Service umfasst Trommelgalvanik, kontinuierliche selektive Galvanik und Gestellgalvanik.

Fast alle metallischen Grundwerkstoffe können mit unseren selbstentwickelten und patentierten Verfahren durch Oberflächenbeschichtungen in ihren Eigenschaften optimiert werden, egal ob sie besonders hart, glatt, verschleißfest oder korrosionsbeständig sein sollen.

Discover our services

We offer all types of heat treatment processes. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. For a complete list and description of heat treatment technologies please select the button.

Hot isostatic pressing (HIP) is used to eliminate porosity. Do you need high mechanical durability and insensitivity to high temperatures for solder joints? We at Aalberts surface technologies offer the solution through brazing.

Polymer coatings can be applied to a wide variety of base materials and offer long-lasting protection. They are particularly well anchored mechanically to the substrate. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance.

With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. Our service includes barrel plating, continuous selective plating and rack plating.

Almost all metallic base materials can have their properties optimised by surface coatings using our proprietary and patented processes, regardless of whether they should be particularly hard, smooth, wear-resistant or corrosion-resistant.

The Aalberts websites use cookies (read more) to analyse website usage and improve usability. We also use third party tracking-cookies to measure user preferences, enable content sharing on social media and interest-based advertising. If you hit 'accept' you allow to us to place the different types of cookies.

privacy overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |