selective finishing of metal surfaces

selective coatings

what is selective coating?

The area of selective coating covers all processes during which, for technical or functional reasons, workpieces are only partially coated. While this allows for the targeted protection of component areas which are subject to heavy loads, the remaining surface remains available for other treatments (e.g. grounding).

How the area to be coated is isolated, whether by targeted coating applications or by masking certain areas of the component, is ultimately determined by the process. With LASOX-COAT® and SELGA-COAT®, Aalberts surface technologies currently offers two selective coating methods.

selective coating with SELGA-COAT®

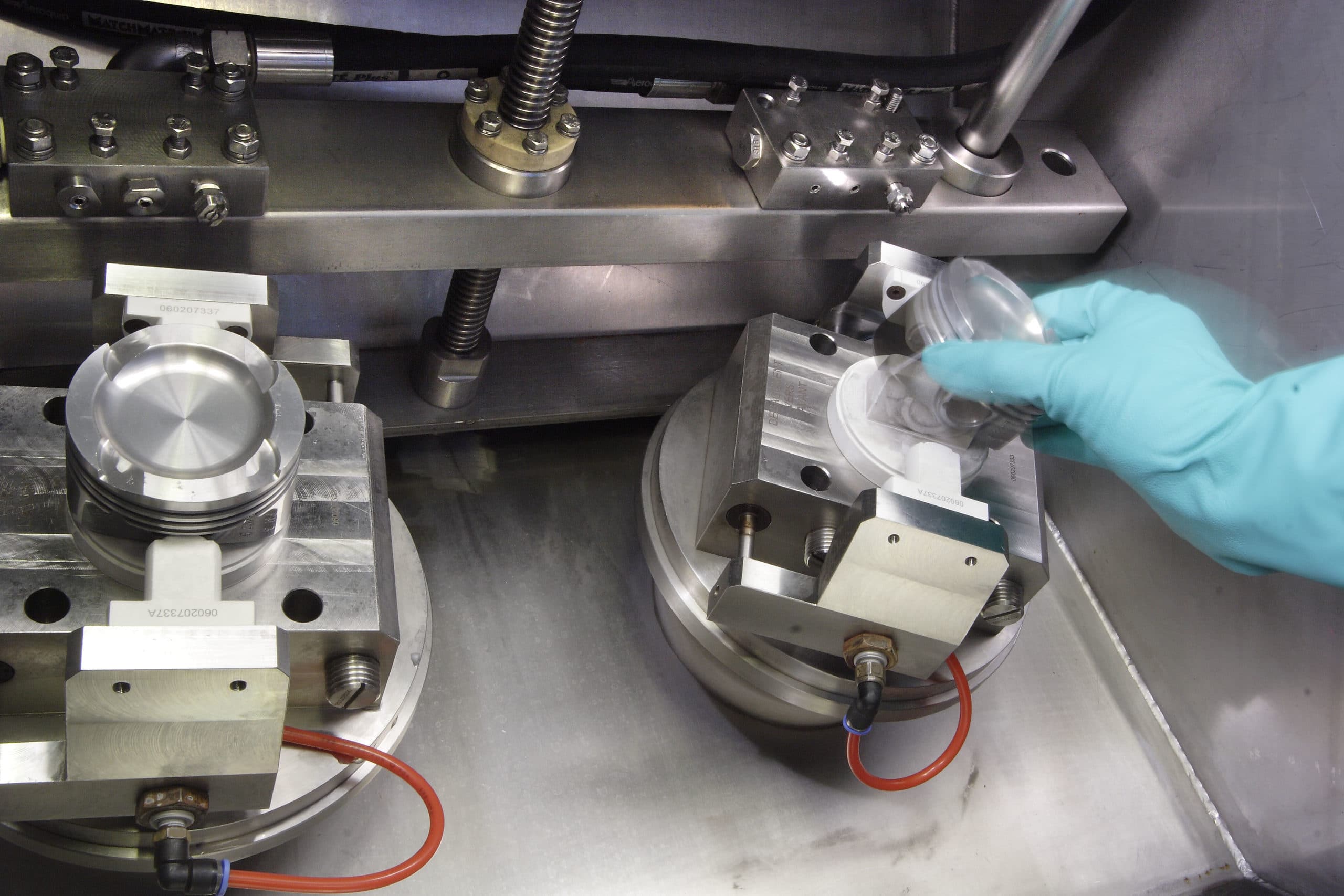

SELGA-COAT® is a selective plating process for metal surfaces. Areas that do not require plating are covered inside a tool with a built-in sealing system. After that, an electrolyte is pumped into the tool housing. It flows around the area to be coated to galvanize it. When aluminum alloys are finished with hard anodizing processes, the workpiece is used as the anode. We offer the SELGA-COAT ® process in Faulquemont. Our dedicated team of experts is there to support you.

selective coating with LASOX-COAT®

LASOX-COAT® is a selective coating process involving the laser-induced formation of aluminum oxide. When exposed to laser radiation, the alloy particles on the surface of the component to be processed melt and vaporize. Oxygen plasma and part of the molten aluminum react to form aluminum oxide (corundum, Al2O3), which now covers the treated surface. Underneath the corundum layer there is a remelt zone whose thickness is approximately 10 times greater.

Since the laser beam is guided across the workpiece surface section by section, the coating duration is proportionate to the area to be coated. Using this selective coating process, we can also create letterings, individual lines or complex shapes and patterns.

properties of SELGA-COAT®

SELGA-COAT® coatings on aluminum materials are partial anodizing or hard anodizing coatings and, in addition to the typical properties in terms of electrical insulation, thermal insulation, corrosion protection, and wear protection, have significantly improved properties and advantages over classically produced coatings. These include:

- fast coating time

- precise layer build-up

- low roughness

- improved hardness

- uniform structures

- no rework and pretreatment necessary

- controlled manufacturing process

- compact production line

- low material input

- sustainable closed loop system “Think GREEN – think SELGA-COAT®”

properties of LASOX-COAT®

The great advantage of selective coating methods, as opposed to electroplating processes, is the fact that they do not require any process chemicals, such as acid electrolytes. That is why it is not difficult at all to have LASOX-COAT® plants authorized. LASOX-COAT® plants are enclosed and rated as Class 4 lasers according to EN 60825-1. Therefore, they can be easily incorporated into existing production lines.

The LASOX-COAT® process increases the wear resistance of component surfaces to a significant extent. It produces extremely hard and durable aluminum oxide, because it does not create any micro-pores in the oxide layer.

In order to increase a component’s resistance to wear, it is not always necessary to coat its entire surface. Even surfaces coated in a “tartan pattern” are already more resistant to wear.

fields of application of SELGA-COAT®

SELGA-COAT® is used in various industries where a high-quality coating of aluminum is required. Especially in the automotive industry, this process has been used for years to selectively anodize different assemblies such as engine pistons, valves and pump housings. Particularly in the case of high volumes, companies benefit from the reduction of processing steps and thus a minimization of costs.

In principle, almost all aluminum alloys can be coated with SELGA-COAT®. However, it is advisable to clarify in each individual case which surface properties are to be given priority and which alloy is then suitable for the SELGA-COAT® process. Depending on the application, the coatings can be produced using Cr6-containing* or Cr6-free electrolytes.

The SELGA-COAT® process can also be adapted to other surface variants. Please contact us and we will work out a solution proposal.

*Request for authorization submitted via Hapoc GmbH & Co. KG.

base materials which can be coated with SELGA-COAT®

| Process | Base Materials |

| SELGA-COAT® |

|

fields of application of LASOX-COAT®

The LASOX-COAT® process is preferably used for the selective coating of those areas of a workpiece surface which are continuously subjected to wear, such as a housing rim repeatedly hit by a cover that is opened and closed or the impeller of a pump which is subject to partial wear. Further common applications include laser markings and labeling on aluminum components for traceability and documentation purposes. The process is also used for the surface treatment of pneumatic valves, proportional valves, brake pistons, hydraulic shutters and pneumatic shutters.

base materials which can be coated with LASOX-COAT®

In general, almost all aluminum alloys may be coated with LASOX-COAT®. In individual cases, however, it is advisable to first clarify the desired surface characteristics in order to determine the type of alloy suitable for the LASOX-COAT® process.

downloads

industries we serve

frequently asked questions - selective coatings

In the case of the SELGA-COAT® process, work is carried out in a closed-loop system. Due to the closed circuit, employees and the environment are protected from harmful influences.

The process designated LASOX-COAT® is a selective oxidation of aluminum surfaces by laser. Since no process chemicals such as electrolytic acids are used, the process is environmentally friendly and is not subject to the usual environmental guidelines.

SELGA stands for SELective GAlvanizing. The SELGA-COAT® process is ideal for the selective galvanization of geometrically sophisticated components produced in high volumes.

During the SELGA-COAT® process, only the functional surface of the component is passed and coated by the electrolyte using electric current. The components do not have to be masked nor do they require any mechanical rework.

process locations

Any questions? Contact us directly or select a process location near you.

Cormenon

France 47.97014060.8907598 ast.cormenon@aalberts-st.com +33 (0) 2 54 73 45 40 show locationFaulquemont

France 49.05433856.6082113 faulquemont@aalberts-st.com +33 387 0043 80 show locationKerpen

Germany 50.88076.6800999 kerpen@aalberts-st.com +49 2237 502 0 show locationUnsere Verfahren

Wir bieten weltweit alle Arten von Wärmebehandlungsprozessen an. Unsere Anlagen sind logistisch eng miteinander verknüpft, so dass Ihnen alle Verfahren zur Verfügung stehen. Erfahren Sie mehr zu unseren Wärmebehandlungsverfahren.

Heiß-Isostatisches Pressen (HIP) dient der Beseitigung von Porosität. Sie benötigen bei Lötverbindungen eine hohe mechanische Haltbarkeit und Unempfindlichkeit bei hohen Temperaturen? Wir bei Aalberts surface technologies bieten die Lösung durch Hartlöten (brazing).

Polymerbeschichtungen können auf viele Grundmaterialien aufgebracht werden und bieten lang anhaltenden Schutz. Sie sind mechanisch besonders gut mit dem Untergrund verankert und bieten verbesserte Gleiteigenschaften und/oder hohe Verschleißfestigkeit.

Mit 40 Jahren Erfahrung in der kontinuierlichen Veredelung von reel to reel können Sie sich auf Aalberts surface technologies verlassen, um innovative Lösungen zu finden. Unser Service umfasst Trommelgalvanik, kontinuierliche selektive Galvanik und Gestellgalvanik.

Fast alle metallischen Grundwerkstoffe können mit unseren selbstentwickelten und patentierten Verfahren durch Oberflächenbeschichtungen in ihren Eigenschaften optimiert werden, egal ob sie besonders hart, glatt, verschleißfest oder korrosionsbeständig sein sollen.

Discover our services

We offer all types of heat treatment processes. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. For a complete list and description of heat treatment technologies please select the button.

Hot isostatic pressing (HIP) is used to eliminate porosity. Do you need high mechanical durability and insensitivity to high temperatures for solder joints? We at Aalberts surface technologies offer the solution through brazing.

Polymer coatings can be applied to a wide variety of base materials and offer long-lasting protection. They are particularly well anchored mechanically to the substrate. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance.

With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. Our service includes barrel plating, continuous selective plating and rack plating.

Almost all metallic base materials can have their properties optimised by surface coatings using our proprietary and patented processes, regardless of whether they should be particularly hard, smooth, wear-resistant or corrosion-resistant.

The Aalberts websites use cookies (read more) to analyse website usage and improve usability. We also use third party tracking-cookies to measure user preferences, enable content sharing on social media and interest-based advertising. If you hit 'accept' you allow to us to place the different types of cookies.

privacy overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |