automotive

heat treatment and surface technologies for the automotive industry: innovative, reliable, sustainable

the specialist for the automotive industry

The automotive industry is a fast-changing, dynamic, and innovative sector. And it demands high-quality, economical and reproducible solutions. From slip coatings of moving parts for reduced friction, high-quality hardening and tempering for automotive components, to protection against corrosion or scratch-resistant paintwork, for decades Aalberts surface technologies has been a powerful partner for the industry.

Our name is synonymous with the development, manufacture and refinement of functional and heavy-duty surface coatings and heat treatment for metallic and non-metallic materials. With over one thousand successful projects completed, we continue to fine-tune our expertise and gain a wealth of experience that our customers benefit from.

Every day, we treat several million parts in our plants. While each year, Aalberts surface technologies functionally refines more than one billion components. There is virtually no automobile in the world that does not contain a component that we have treated.

innovative designs

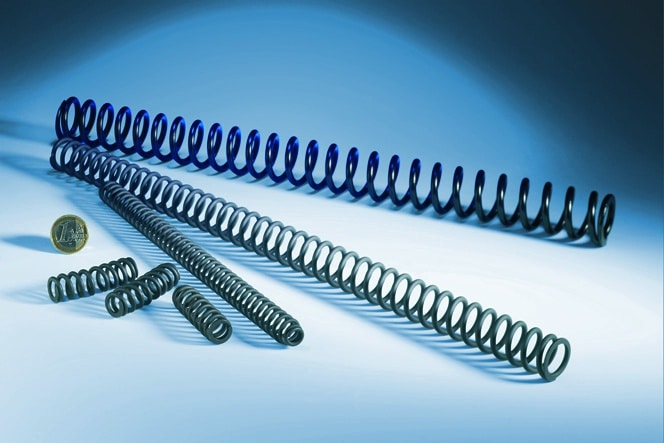

Aalberts surface technologies offers a wide range of high-quality treatments for the automotive industry. The treatments’ properties are different or combined. On the production side, our products accelerate processes, increase service life and lead to reduced costs. This benefits the customer in numerous ways, from high-performance engine components, lower fuel consumption, a velvety feel to the interior, and durable components with excellent corrosion protection. Tailor-made properties can extend the service life of moving components and reduce maintenance costs.

high demands, dependable results

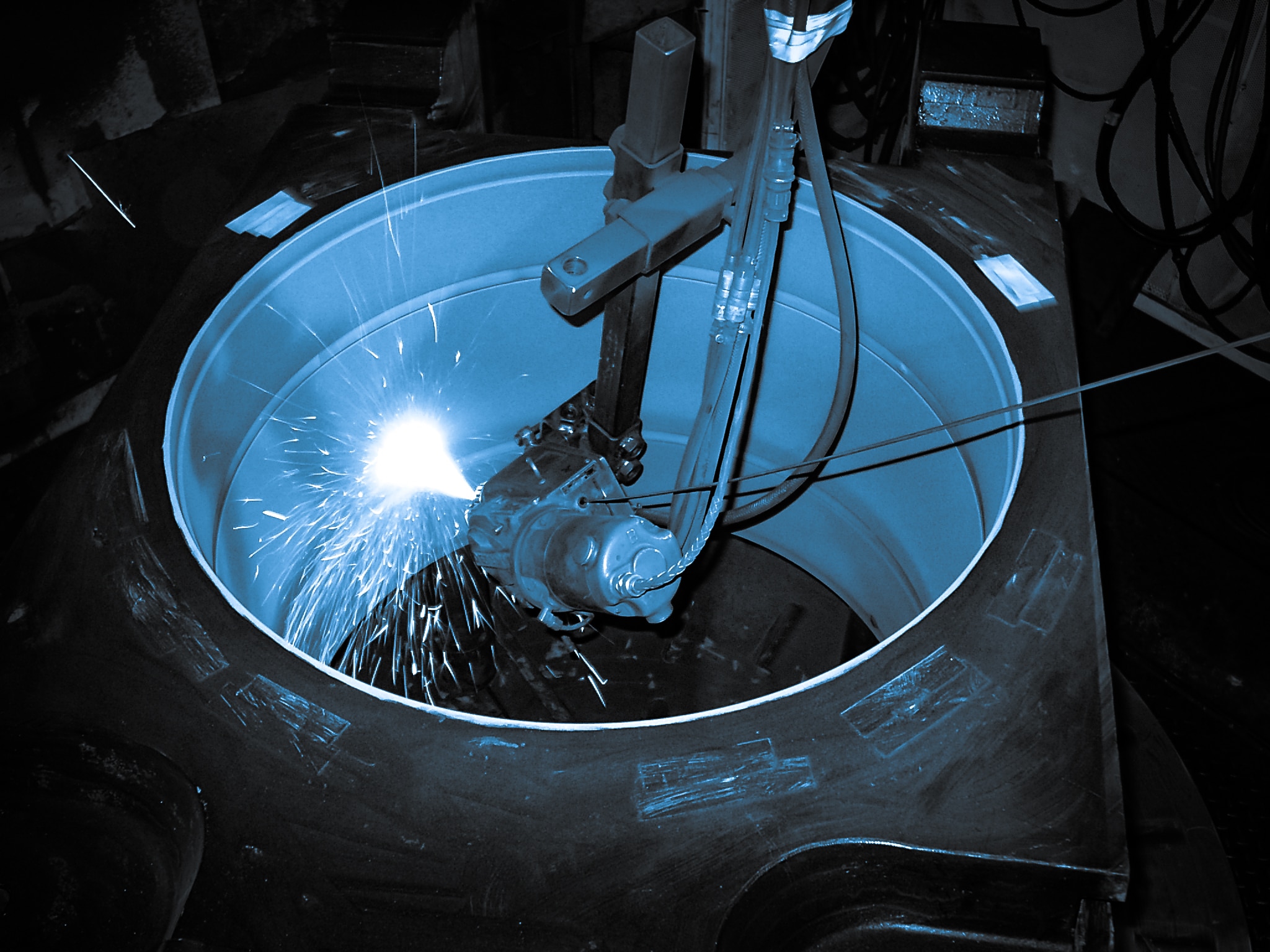

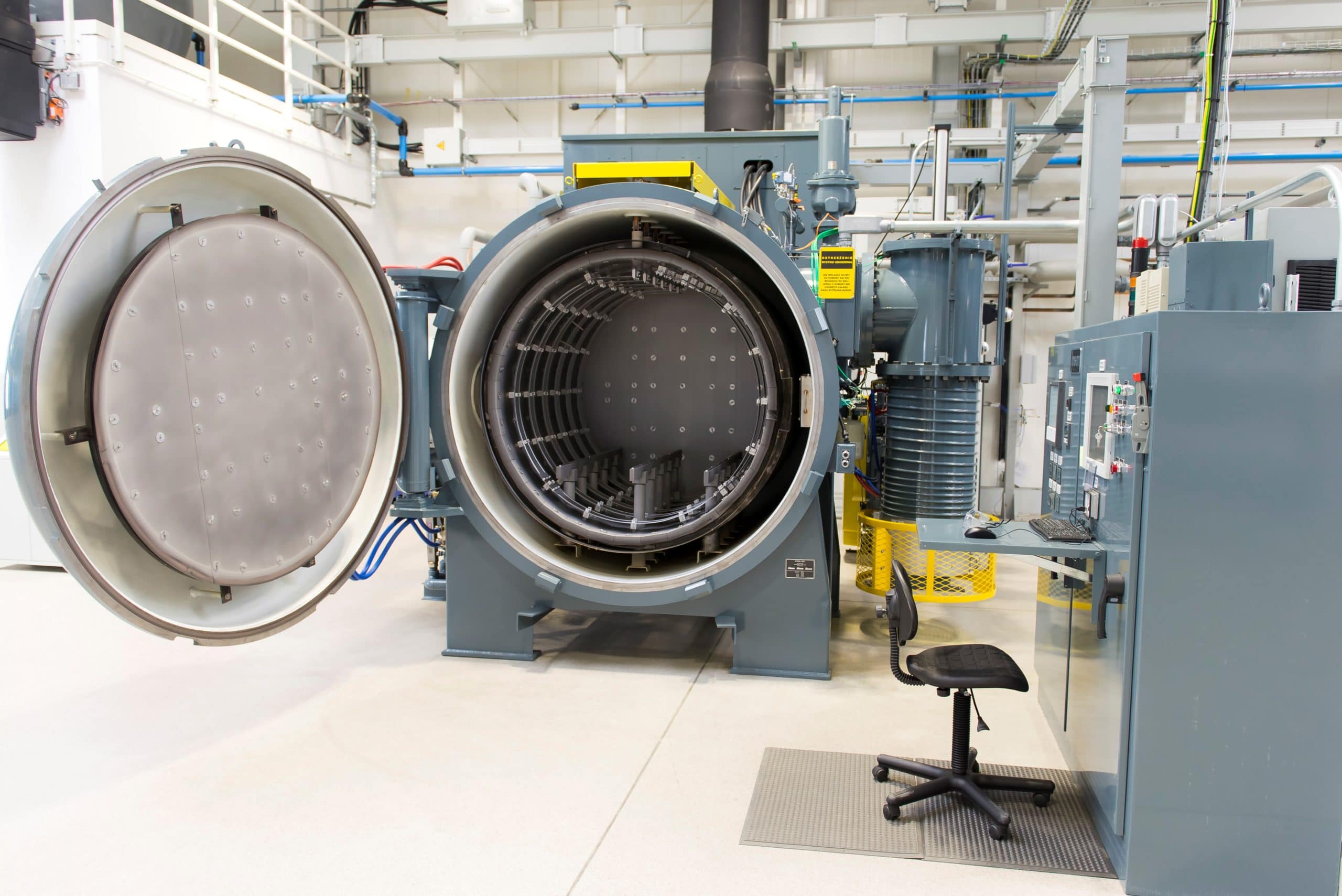

Our treatments for cars are extremely effective and meet the high standards and strict regulations of the automotive sector and its suppliers. Proven processes such as annealing in vacuum, hydrogen brazing, dip spinning, fully automatic wet painting or hardening and tempering are used to apply optimum protect to automotive parts or production machines.

Our comprehensive quality management always ensures the latest automotive industry standards are adhered to, and guarantees compliance with industry-specific requirements for material composition, environmental specifications and treatment tolerances.

Corrosion protection, friction reduction, wear protection, increase strength or scratch resistance are just some of the demands we place on our treatments. Depending on which component you produce for the automotive sector, additional individual treating properties can maximise component safety and performance. There are many optimisation possibilities.

benefits of automotive industry

corrosion protection

Excellent rust protection is one of the most important treating for the automotive industry. And with good reason:

- In the case of load-bearing parts, corrosion can represent a safety risk over the long term

- Oxidation has a negative effect on the value of the vehicle

- Car paint no longer adheres to corroded areas and forms blisters

- Repairs are costly – red rust often reappears in the same places

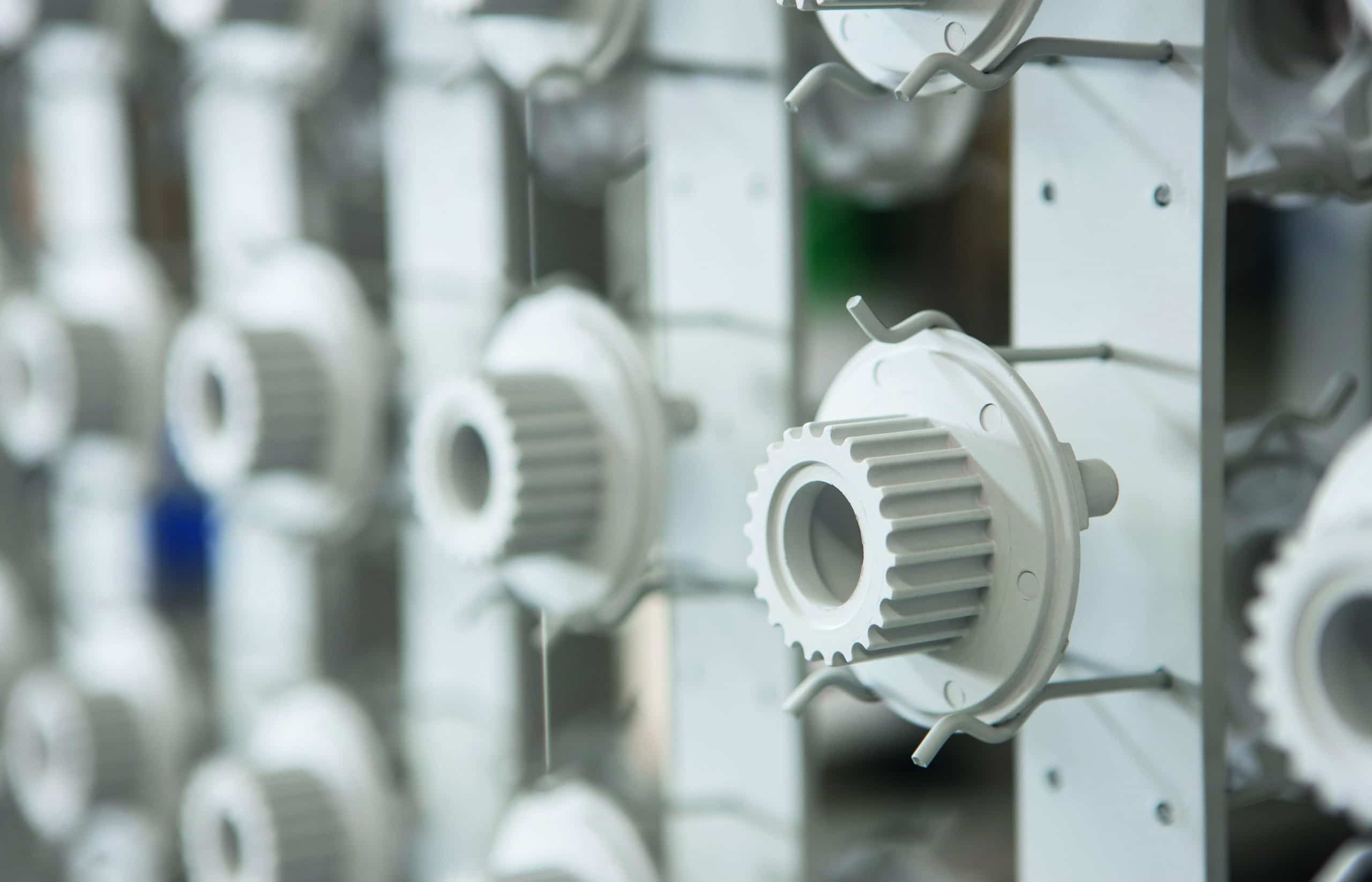

Hard anodizing HART-COAT® and electroless nickel DURNI-COAT® are indispensable as corrosion and wear protection coatings for transmission components, valve casings, fuel pumps and exhaust gas recirculation systems.

In selective galvanic finishing (SELGA-COAT®), defined surface areas are treated by using the electrolyte in closed tools only at the intended points. The partial coating is used for wheel hubs and bearings, valves (such as injection pumps), engine pistons, valve pistons, brake system components, clutch components, pump housings and intermediate plates, amongst others.

Our innovative and highly efficient zinc flake coatings provide reliable corrosion protection for the automotive industry. The chromium-VI-free zinc flake system, for example, actively counteracts oxidation on steel components and provides an excellent adhesion base for functional or decorative topcoats.

With cathodic dip painting, we produce resistant anti-corrosion coatings for your cars – and their installed components. It is perfectly suited as a duplex coating on zinc.

The corrosion-resistant anti-friction coating TempCoat®, with non-stick properties, gives many types of plastics, ceramics and metals enormous surface resistance: Our customers in the automotive industry benefit from these durable surface finishes for safety-relevant belt systems or extendable bicycle racks.

more options in downsizing & lightweight construction

Smaller, lighter, smoother. The downsizing demands placed on engine components are challenging and require ever-higher quality components. Our systems provide customers’ components with the material properties they demand.

The automotive industry is constantly looking to increase performance and reduce the weight of the vehicles they produce. Austempered materials have a proven track record of providing strength, toughness and dependability for safety critical components including suspension systems, and drivetrain applications.

The following will provide a good overview on what applications would be helped by Austempered Steel, Carbo-Austempered Steel, and Austempered Ductile Iron

Austempered Steel

- Transmission Components

- Engine valvetrain

- Bolts, Brackets, Clips and Clamps

- Structural and Chassis Components

Carbo-Austempered Steel

- Output, Pump and Drive Shafts

- Transmission pawls and gears

Austempered Ductile Iron

- Control Arms and Steering Knuckles

- Planet carriers and differential cases

- CV Joints

- Wheel Hubs

- Brake calipers and carriers

Austempered Gray Iron

- Brake rotors

Increasingly, new possibilities for reducing cubic capacity are opening up for designers, such as through turbochargers or compressors. DURNI-COAT®-coated compressor wheels have a significantly higher thermomechanical load capacity. One of its key impacts is on the supply of exhaust gases on the compressor side of a turbocharger, as the finest particles put excessive stress on the compressor wheel at immense speeds.

In these systems, extremely small-gap dimensions are required to enable lower hydraulic pressures and reduced oil circulation volumes. This makes it possible to build smaller, more cost-effective oil pumps that result in reduced CO2 emissions. The control edges of the pistons are electroless nickel plated using the DURNI-COAT® process. The coating is then ground down precisely. The coating reduces the risk of “piston jamming” due to foreign particles and improves the tribological properties of the pistons.

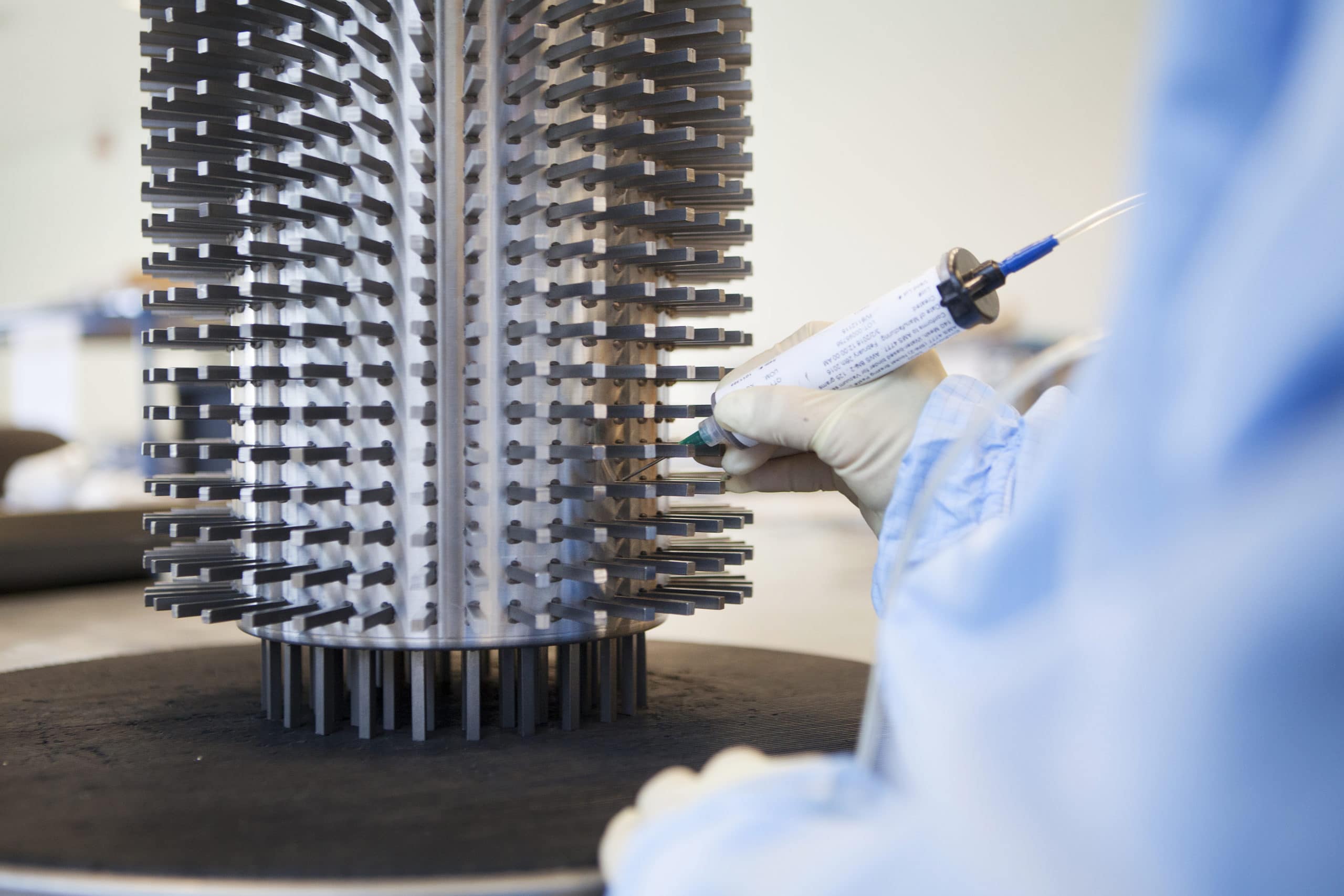

In addition to efficient treatment for automotive components, shortened cycle times and low-maintenance machines play an important role in automotive engineering.

Today, the industry is faced with the challenge of process optimisation on a daily basis. The number of fully automated processes continues to rise, with robots increasingly performing monotonous or hazardous activities. Yet the purchase of expensive systems is only justified if the automation technology works sustainably and economically.

Our wide range of anti-friction coatings, anti-adhesion coatings and protective treatments improve reliability in automation and significantly reduce downtimes. At the same time, they are easy to clean due to dirt-repellent surfaces. Our treatments are cost-effective and sustainable, helping to reduce resource use and cut downtimes.

STAINIHARD® NC

For years we offer Stainihard® NC. This process ensures a strong improvement of the wear resistance and the fatigue strength, but also prevents against the well-known “galling”. This while the corrosion resistance remains unchanged and in some cases is even improved. Generally it offers the industry an excellent solution when wear and galling resistance must go hand in hand with good to very good corrosion resistance. In the automotive industry there is a large variety of products and parts that will benefit from this treatment

Just one example is a solenoid valve/switch to function properly, a stainless steel tube/bushing is needed between the copper winding and the soft iron core. One of the advantages of austenitic stainless steel compared to steel is its non-magnetic properties. The disadvantage, however, is that the soft iron core is harder and therefore the stainless steel housing will show excessive wear. With Stainihard it is possible to apply a wear-resistant zone even to the inside (even if it is closed at one end) of a product. These Stainihard-treated sleeves easily pass the prescribed lifetime test.

individual solutions for heat and surface treatment in the automotive industry

High-quality workmanship, durability, innovation and environmental protection are the foundation of long-term success in the automotive industry. To satisfy these high demands, our engineers develop exclusive surface technologies that provide tailor-made solutions to your problem. Contact our technological consulting team now and let our products inspire you.

applicable processes

relevant process locations

get in touch

Select your preferred process location or contact us directly.